J23 Series C Frame Inclinable Press

It As a widely recognized hydraulic press, our JH23 series C frame inclinable press has got quite mature after long-term improvement. Its body and base is designed to be separated. It can serve as a tilting type press, making the material cutting-off and the processing degree adjustment quite convenient.

Feature

1. The rotating key positive clutch is used in our JH23 series C frame inclinable press. This clutch has simple structure, making the operation and fixing quite convenient.

2. There is a mechanical overload protector in the slide.

3. As a durable product, our punch press is much heavier than many other machines of the same type.

4. The rolling bearings are adopted in the transmission mechanism of the JH23 series C frame inclinable press because their working noise is quite small.

5. For the models heavier than J23-80, a pneumatic twin cylinder is used to lower the fluctuation of the balance force, and keep the slide and the upper die balance. Thus the punch press machine can be more stable during the operation. Besides, it can also 1) avoid the clash and noise caused by the gear reversing during transmission; 2) eliminate the clearance between connecting rod and slide, 3) reduce the compact force and abrasion of some components; 4) and avoid the accident caused by falling slide when braking or connecting rod broke.

Basic configuration

J23-6.3T, J23-10T, J23-25T, J23-40T, J23-63T C frame inclinable press

AC connector, middle connector, thermal relay, auxiliary joint, control button, electric motor, mechanical overload protector

J23-80T, J23-100T C frame inclinable press

AC connector, middle contactor, thermal relay, auxiliary joint, control button, mechanical overload protector, air filter and pressure reducing valve, electric motor, balancing cylinder, air tank, electromagnetic valve

Technical parameter

| Parameter | Unit | J23-6.3 | J23-10 | J23-16 | J23-25 | J23-35 | J23-40 | J23-63 | J23-63 | J23-80 | J23-100 | J23-125 | |

| Nominal capacity | KN | 63 | 100 | 160 | 250 | 350 | 400 | 630 | 630 | 800 | 1000 | 1250 | |

| Nominal pressure stroke | mm | 2 | 2 | 2 | 2.5 | 3.5 | 6 | 6 | 7 | 7 | 7 | 8 | |

| Nominal slide stoke | mm | 35 | 45 | 55 | 65 | 80 | 90 | 110 | 110 | 120 | 140 | 150 | |

| Stroke speed | High speed | times/ min | 170 | 145 | 120 | ||||||||

| Low speed | 55 | 50 | 45 | 50 | 40 | 38 | 38 | 35 | |||||

| Maximum die set height | mm | 150 | 180 | 220 | 270 | 290 | 320 | 360 | 390 | 440 | 480 | 500 | |

| Die height adjustment | mm | 30 | 35 | 45 | 55 | 60 | 65 | 80 | 80 | 90 | 100 | 100 | |

| Throat depth | mm | 110 | 130 | 160 | 200 | 220 | 250 | 260 | 310 | 350 | 380 | 390 | |

| Distance between posts | mm | 150 | 180 | 220 | 270 | 280 | 340 | 350 | 420 | 450 | 560 | 550 | |

| Slide bottom size | Left-Right | mm | 140 | 170 | 200 | 250 | 250 | 300 | 300 | 400 | 430 | 540 | 540 |

| Front-Back | mm | 120 | 150 | 180 | 220 | 220 | 220 | 260 | 360 | 360 | 480 | 480 | |

| Stemhole size | Diameter | mm | 30 | 30 | 40 | 40 | 40 | 50 | 50 | 50 | 60 | 60 | 60 |

| Depth | mm | 55 | 55 | 60 | 60 | 60 | 70 | 70 | 70 | 75 | 75 | 75 | |

| Working table size | Left-Right | mm | 310 | 370 | 450 | 560 | 610 | 700 | 760 | 860 | 950 | 1080 | 1100 |

| Front-Back | mm | 200 | 240 | 300 | 370 | 400 | 460 | 480 | 570 | 650 | 710 | 720 | |

| Working table thickness | mm | 30 | 35 | 40 | 50 | 60 | 65 | 80 | 80 | 100 | 120 | 130 | |

| Max. tilting angle | ° | 45 | 35 | 35 | 30 | 30 | 30 | 30 | 20 | 20 | 15 | 13 | |

| Working table surface height | mm | 750 | 730 | 750 | 800 | 815 | 850 | 810 | 850 | 850 | 850 | 860 | |

| Dimensions | Front-Back | mm | 780 | 900 | 1150 | 1345 | 1460 | 1721 | 1810 | 1958 | 2060 | 2254 | 2200 |

| Left-Right | mm | 620 | 665 | 847 | 950 | 1058 | 1335 | 1350 | 1500 | 1715 | 1790 | 1790 | |

| Height | mm | 1503 | 1658 | 1910 | 2130 | 2225 | 2488 | 2740 | 2868 | 3290 | 3625 | 3590 | |

| Distance Between Foundation Bolts | Front-Back | mm | 530 | 610 | 780 | 920 | 1020 | 1060 | 1180 | 1300 | 1360 | 1550 | 1710 |

| Left-Right | mm | 314 | 394 | 450 | 600 | 650 | 750 | 850 | 920 | 1010 | 1130 | 1110 | |

| Motor Power | KW | 0.75 | 1.1 | 1.5 | 2.2 | 4 | 5.5 | 5.5 | 7.5 | 7.5 | 11 | 11 | |

| Approx. weight | KG | 420 | 595 | 1095 | 1830 | 2650 | 3600 | 4200 | 5580 | 8020 | 10800 | 12035 | |

Links:https://globefindpro.com/products/77083.html

-

Hydraulic Press Brake

Hydraulic Press Brake

-

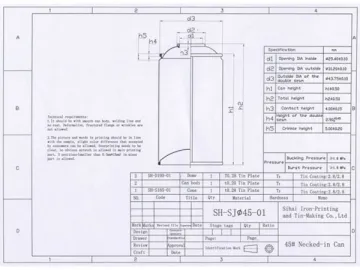

45mm Diameter Aerosol Can

45mm Diameter Aerosol Can

-

Four Column Hydraulic Press

Four Column Hydraulic Press

-

Uncoiling, Leveling and Cutting Line (Thin Plate)

Uncoiling, Leveling and Cutting Line (Thin Plate)

-

Artificial Podocarpus

Artificial Podocarpus

-

Artificial Monstera Deliciosa

Artificial Monstera Deliciosa

-

Z Channel Rolling Machine

Z Channel Rolling Machine

-

Plate Bending Roll for Shipbuilding Industry

Plate Bending Roll for Shipbuilding Industry

-

Artificial Cypress

Artificial Cypress

-

Artificial Stellaria Alsine

Artificial Stellaria Alsine

-

Artificial Butterfly Orchid

Artificial Butterfly Orchid

-

JH21 Series C Frame Press

JH21 Series C Frame Press