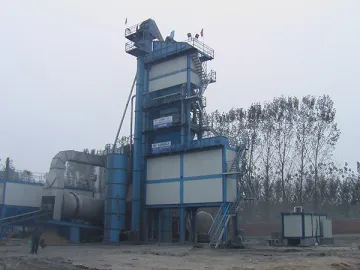

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

Designed for large-scale road construction and road maintenance projects,WCB600 stabilized soil mixing plant has high productivity that reaches up to 600 tons per hour. It may mix gravel stabilized soil used in the paving of high-grade highways, urban and rural roads, airport runways, railways and so on. It is also able to manufacture lime stabilized soil or special concrete which can be compacted. There is a discharge gate at the bottom of this building material batch mixer, leading to easy maintenance. Our specialized persons will assist you with the installation and supply professional technical instruction, so as to guarantee good security and correction operation.

Features

1. The stabilized soil mixing plant only needs one operator.

2. Both the dedicated powder oblique cone and the screw feeder come with large outlets, so as to avoid blocking phenomenon caused by being exposed to moisture.

3. The speed of this industrial batch mixing system is regulated by a computer, which ensures stable operation, high production efficiency and less failure rate. The control system for the continuous mixing plant can carry out several functions, including startup and shutdown process management, state inspection, failure alarm, overload warning, low-voltage protection and so on.

4. Within the motor-driven reduction gear, the big gear wheels rotate to realize synchronous drive. With high stability and long useful life, the reduction gear of the stabilized soil mixing plant is resistant to impact vibration and overload.

Technical Specifications

| Model | WBS600 | |

| Productivity (t/h) | 600 | |

| Volume of powder hopper (m3) | 6 | |

| Discharging volume (m3) | 7.5 | |

| Aggregate size (mm) | ≤60 | |

| Grading type | 3-5 | |

| Grading precision | Aggregate | ± 2% |

| Cement | ± 1% | |

| Water | ± 1% | |

| Main power | 166 | |

All Pictures

Links:https://globefindpro.com/products/77494.html

-

Electric Drill

Electric Drill

-

Diamond Core Drill

Diamond Core Drill

-

LB-1500 Asphalt Mixing Plant (90-120 Ton/h)

LB-1500 Asphalt Mixing Plant (90-120 Ton/h)

-

WCB300 Stabilized Soil Mixing Plant (300 Ton/h)

WCB300 Stabilized Soil Mixing Plant (300 Ton/h)

-

Sander Polisher

Sander Polisher

-

LB-4000 Asphalt Mixing Plant (240-320 Ton/h)

LB-4000 Asphalt Mixing Plant (240-320 Ton/h)

-

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

-

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

-

Electric Planer

Electric Planer

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

-

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

LB-500 Asphalt Mixing Plant (30-40 Ton/h)