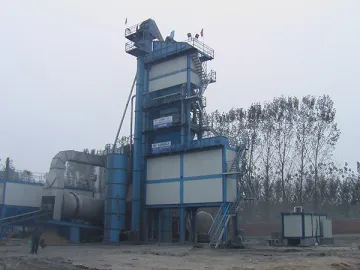

LB-500 Asphalt Mixing Plant (30-40 Ton/h)

The maximum production capability of LB-500 asphalt mixing plant is 40 tons per hour. It can be applied in expressway, runway, city road and other projects. Our asphalt batch mix plant adopts a modular design, and comes with special structure, convenient transportation and easy installation.

Features

1. Due to the modular structure, the modules of asphalt mixer are flexible and may be changed in line with your requirements. Two professional technicians will be dispatched to assist your asphalt mixing plant installation, avoiding possible installation errors.

2. The cold aggregate framework of this industrial batch mixer is provided with 4 hoppers. With the help of frequency control, its speed can be adjusted according to set productivity and proportioning requirements. The no-material alarm light is able to warn operators of material shortage or inner blockage. Manufactured from high tenacity rubber, the aggregate belt and feeding belt are easy to clean.

3. The lining of drying drum makes use of manganese steel as raw material because of good ruggedness, wear resistance and high durability. The burner of asphalt mixing plant can be fueled by diesel, heavy oil or natural gas to satisfy demands of different operating conditions.

4. This range of building material mixing plant is under the control of a microprocessor. With a complete set of control and display system, the machinery is capable of storing formulas, set parameters and production data. The standard equipment is composed of a work station, including high-precision color display, keyboard, mouse, printer and so forth. It shows various parameters on its widescreen LCD and monitors the operation of each component at any moment. The asphalt mixing plant allows manual intervention if necessary.

Main Parameters

| Model | LB-500 |

| Productivity | 30-40 ton/h (water content≤5%) |

| Fuel | Diesel, heavy oil, natural gas, coal |

| Cold aggregate framework | Frequency control |

| Drying drum | ¢1200*6080MM |

| Burner | Proportional adjustment |

| Hot aggregate elevator | Centrifugal discharge |

| Vibrating and screening device | Four-stage |

| Metering device | Computer/Aggregate controller |

| Metering precision (static) | Aggregate±0.5% Asphalt, powder±0.25% |

| Mixer | Forcing type |

| Filtering area | 245M2 |

| Intermittent mixing | 500KG/batch |

| Mixed material storage | 30T |

| Installed power | 182.2KW |

| Floor area | 30*28M |

All Pictures

Links:https://globefindpro.com/products/77488.html

-

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

LB-2500 Asphalt Mixing Plant (150-200 Ton/h)

-

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

WCB500 Stabilized Soil Mixing Plant (500 Ton/h)

-

Electric Planer

Electric Planer

-

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

LB-1000 Asphalt Mixing Plant (60-80 Ton/h)

-

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

WCB200 Stabilized Soil Mixing Plant (200 Ton/h)

-

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

WCB600 Stabilized Soil Mixing Plant (600 Ton/h)

-

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

LB-2000 Asphalt Mixing Plant (120-160 Ton/h)

-

HZS-150 Concrete Batching Plant (150m3/h)

HZS-150 Concrete Batching Plant (150m3/h)

-

Dental Apron

Dental Apron

-

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

LB-3000 Asphalt Mixing Plant (180-240 Ton/h)

-

Cordless Drill

Cordless Drill

-

Calcium Alginate Dressing

Calcium Alginate Dressing