D Series Eco-Friendly Pigment Paste for Textile Dyeing

Buy our D series eco-friendly pigment paste and use it to dye a wide range of materials, such as cotton, linen, polyester fiber, acrylic fiber, and other fabrics, garment, and yarns.

Color Swatch Card for D Series

Good to Know

1. The D-series eco-friendly pigment paste meets the related standards of Öeko-Tex 100:2012 Product Class II. Öeko-Tex certification system has put strict restrictions on the use of methanol, heavy metal, phthalate, APEO, and 24 types of aromatic amines.

2. This dyeing material normally provides happy decades of service. A total of 25 pigment types offer a full spectrum of basic colors, which allow you easily to create a new color between them. For more information, please refer to our color swatch card.

3. Uniform pigment size distribution and good flowability are two major benefits of our eco-friendly colorant for its end users.

4. The D-X00X series pigment paste is color fast, with great ability to withstand light and resist sublimation.

Important

1. To test the content of methanol, heavy metal, phthalate, APEO, and 24 types of prohibited aromatic amines, you should first make a thin paste that contains 10% of pigment and print it onto a piece of cotton cloth. Please test the sample of your pigment mixture before using the finished mixture for batch dyeing.

2. Ensure an even mix of pigment paste before use. It is not unlikely that there might be pigment particles precipitating from the mixture after it has long been unused. If such is the case, mix the paste thoroughly and filter out the sediments.

3. Please refer to our MSDS for more safety issues that you should watch out for before, during and after use.

Pigment Paste Recipe and Use (for Reference Only)

1. Pad Dyeing

Process

Bleached Fabrics—Apply cationic surfactant to the surface of fabrics by way of soaking and pressing---Baking---Add pigment paste to the fabrics via soaking and pressing---Drying---Apply Binder to the fabrics through soaking and pressing---Fix the color to the fabrics (often via mordant)---Cleaning ---Finished Print

Note

Add a proper amount of cross-linker if you are trying to dye a deep color. Try a little deepening agent to increase the dyeing depth. Use the wet rub-fastness enhancer to replace part of the binder in order to improve color fastness and feel of the fabrics.

Pad Dyeing Solution

| Recipe | Light Color | Light-Moderate Color | Deep Color |

| D series pigment | Less than 2g | 2-10g | 20-50g |

| Binder | 10g | 20-30g | 50-80g |

| Water | X | X | X |

| Total | 1L | 1L | 1L |

2. Pad Dyeing with Modified Fabrics

A. Dyeing Equipment: Industrial washer (suitable for coloring cotton garment and woven clothes)

B. Fabrics Pre-Treatment

Add water to the required level---Use soda ash to adjust PH value---Add cationic surfactant---Run the washer for 2-3 minutes---Throw in the garment to be dyed---Raise the washing temperature to 60°C (in 2°C/minute increment) and maintain that temperature level for 20 minutes---Pour more water to washer---Heat the water to 60°C and stay at that temperature level for 3-5 minutes---Cleaning

Paste Recipe

| Cationic Surfactant (for fabrics modification) | ≥4g/L |

| Soda Ash | Adjust PH value and maintain the PH level between 9 and 9.5 |

| Bath Ratio | 1:20-30 |

Note

Make sure the dye modifier is evenly mixed. After mixing, clean any remaining soda ash off of the fabrics in case it would affect the dyeing uniformity and efficiency.

C. Dyeing Process

Add water to required level---Adjust PH value to 7---Pour Pigment Paste and Mix it Evenly---Throw in Garment and water---Let the washer work for 10 minutes---Raise washing temperature to 60°C (in 2°C/minute increment) and maintain that temperature level for 10 minutes---Check if the dyed pattern is all right---Add binder and keep the temperature unchanged for 10 minutes---Wash the Garment---Add garment softener and raise temperature to 40°C for a 5-10 minute washing---Use soap to wash the garment (at 85°C for 10 to 15 minutes)---Washing with hot water---Washing with cold water---Drying

Dyeing Solution

| D Series Pigment | x% |

| Carbamide | 5 ~20 g/L (help with dissolution and fiber swelling) |

| Paregal O | 1 ~2 g/L (reduce the chances of binder adhering to the wall of washer) |

| Binder | 2 ~8 g/L (use rub-fastness improver to replace part of the binder for improving the feel of cloth) |

| Softener | X% |

| Soda Ash | 5 ~30g/L(washing with soap) |

| Bath Ratio | 1:20-30 |

Links:https://globefindpro.com/products/77706.html

-

76 Series Alcohol-Soluble Letterpress Printing Ink for Plastic Film

76 Series Alcohol-Soluble Letterpress Printing Ink for Plastic Film

-

QY301OPS,QY302OPS Air Tire Inflator

QY301OPS,QY302OPS Air Tire Inflator

-

Wiper Blade

Wiper Blade

-

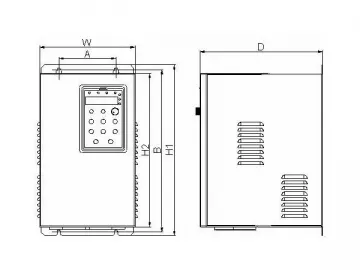

Frequency Inverter (Closed Loop Vector Control VFD)

Frequency Inverter (Closed Loop Vector Control VFD)

-

28mm PM Stepper Motor with Captive Shaft Actuator

28mm PM Stepper Motor with Captive Shaft Actuator

-

Wiper Arm

Wiper Arm

-

Digital Keypad (for Inverter Operation)

Digital Keypad (for Inverter Operation)

-

CD Series Eco-Friendly Pigment Paste for Textile One-Bath Dyeing

CD Series Eco-Friendly Pigment Paste for Textile One-Bath Dyeing

-

Heater Blower Motor

Heater Blower Motor

-

P Series Pigment Paste for Emulsion Tinting

P Series Pigment Paste for Emulsion Tinting

-

I/O Expansion Card (for Inverter Drive)

I/O Expansion Card (for Inverter Drive)

-

54 Series Alcohol-soluble Gravure Printing Ink for Paper

54 Series Alcohol-soluble Gravure Printing Ink for Paper