Frequency Inverter (Closed Loop Vector Control VFD)

KE600 frequency inverter uses a shaft encoder or shaft sensor on the motor to give motor shaft position indication back to the PID controller for correcting position error on the fly. With the shaft encoder, the behavior of the motor is sensed and fed back to the controller for performance monitoring and adjustment. From there, our frequency inverter gets its name: closed loop VFD. Thanks to advanced vector control, accurate V/F ratio adjustment can be achieved, which in turn allows precise control of motor speed and torque.

KE600 closed loop vector control VFD represents an improvement over the KE300 series in dealing with complicated motor load applications. The closed loop vector control variable frequency drive takes the control performance of any asynchronous motor to higher levels. KE600 frequency converter is widely used in applications where heavy loads need to be lifted, printing, dyeing and packaging done accurately, and certain lengths of materials need to be wound up into a roll. These occasions usually have high requirements for accurate speed regulation, quick response to changes in load torques, and high torque output at low frequency.

Features of Frequency Inverter

1. Energy Efficiency

Many applications do not require the motor to operate at full speed all the time. Lacking speed adjustment means wasting energy. With our inverter, customers from almost any motor power application fields can find the most energy saving solution for their industrial processes.

2. Compatibility with A Variety of Shaft Encoders

This adjustable-speed drive is compatible with kinds of encoders such as A.B.Z differential encoder and open collector encoder.

3. Switching between Drive Modes

Our frequency inverter supports two sets of motor parameters. Hence switching between two motor drive modes can be achieved by adjusting those parameters.

4. User-Friendly Interface

RS485 international standard communication interface is optional. MODBUS communication protocol is supported.

5. Accurate Parameters Identification

Automatic fine tuning of motor parameters allow more accurate parameters identification.

6. High Precision Torque Control

Torque control can be achieved under PG vector control mode. The control accuracy reaches ±5%, making it easy to complete tension control of a coiler by using the AC drive.

7. High Starting Torque

The closed loop vector control VFD can provide 150% starting torque (under vector control without PG) when the frequency is 0.5Hz. It offers 180% torque at zero speed (under vector control with PG) when the frequency is 0.5Hz.

8. Fast Dynamic Response

Dynamic response time is less than 5ms under vector control without PG.

9. Powerful Expansion Capability

Customers can choose I/O expansion cards, injection molding machine cards, PG cards and communication cards based on what they need.

10. Powerful Upper Computer Software

Our upper computer software supports uploading and downloading between frequency inverter and PC as well as real-time display.

Control Functions of Frequency Inverter

1. Common DC Bus: A number of frequency inverters can share a common DC bus and their capacities are automatically balanced.

2. Torque Control: Torque control with and without PG are all available.

3. Overload Protection: Torque during operation is automatically controlled to prevent frequent tripping caused by overcurrent.

4. Swing Frequency Control: Multiple triangular wave frequency control is exclusively used for spinning.

5. Fixed Time/Fixed Length/Counting Control

6. Overvoltage & overcurrent control: The current and voltage during operation are all automatically controlled to avoid tripping operations due toovercurrent and overvoltage.

7. Rotate Speed Trace and Restart: Smooth start of rotating motor without impact can be achieved. Hence, safety of the motor and the load can be protected to the maximum degree.

8. Quick View of User Parameters: Quick view of parameters set by users contributes to convenient debugging.

9. Fault Protection: The variable frequency drive provides protection in case of faults like overload, phase loss, short circuit, overcurrent, overvoltage, undervoltage, etc. Detailed information of operation status of the motor speed controller is recorded. The inverter drive also has automatic recovery function.

Special Functions of Frequency Inverter

Multiple Motor Switching: The variable frequency drive controls parameters of two motors. Switching between these two motors can be completed.

Abundant Accessories: Braking components, I/O expansion card, differential input PG cards, open collector (OC) input PG cards, injection molding machine cards and communication cards.

Powerful Upper Computer Software: Supporting operations of KE600 parameters and monitoring of real-time operation parameters.

Human Machine Interface

1. LED Display: The set frequency, output frequency, output voltage, output current, and other parameters can be displayed.

2. Multifunction Key: QUICK/JOG key can serve as a multifunction key.

Environmental Restrictions

1. Temperature: -10°C~40°C. Derating of the variable frequency drive is required if working temperature is higher than 40°C and the working temperature should not exceed 50°C. The variable speed drive should be derated by 4% with an increase of 1°C in temperature.

2. Humidity: ≤90%RH, no moisture condensation

3. Altitude: ≤1000m: rated power output; >1000m: derated power output

4. Storage Temperature: -20°C ~60°C

Specifications

| KE600 Close Loop Vector Control Variable Frequency Drive | |||

| Input | Input Voltage | 3AC 220V±15% 3AC 380V±15% | |

| Input Frequency | 47~63Hz | ||

| Output | Output Voltage | 0~Rated voltage | |

| Output Frequency | V/f:0~3000Hz, VC: 0~300Hz | ||

| Control Feature | Control Mode | V/f , SVC, VC, Torque control | |

| Operation Command Mode | Keypad control, Terminal control, Serial communication control | ||

| Frequency Setting Mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined and switched in various modes. | ||

| Overload Capacity | 150% 60s, 180% 10s, 200% 3s. | ||

| Starting Torque | 0Hz/180% (VC); 0.5Hz/150% (SVC) | ||

| Speed Adjustment Range | 1:1000 (VC); 1:100 (SVC) | ||

| Speed Control Precision | ±0.5% (SVC); ±0.02% (VC)) | ||

| Carrier Frequency | 0.5--16.0kHz, automatically adjusted according to temperature and load characteristics | ||

| Frequency Accuracy | Digital setting: 0.01Hz Analog setting: maximum frequency ×0.05% | ||

| Torque Boost | Automatically torque boost; manually torque boost 0.1%~30.0% | ||

| V/f Curve | Three types: straight line, multiple point and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | ||

| ACC/DEC Mode | Linear/S curve; four kinds of ACC/DEC time, range 0.1s~3600.0s | ||

| DC Braking | DC braking when starting and stopping DC braking frequency: 0.0Hz~maximum frequency, braking time: 0.0s~36.0s; Braking current: 0.0%~100.0% | ||

| Jog Operation | Jog operation frequency: 0.0Hz~maximum frequency Jog ACC/DEC time: 0.1s~3600.0s | ||

| Simple PLC & Multi-Step Speed Operation | Max. 16 steps speed running via built-in PLC or control terminal. | ||

| Built-in Dual PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | ||

| Automatic Voltage Regulation | Keep output voltage constant automatically when input voltage fluctuates | ||

| I/O Terminals | Input Terminals | Programmable DI: 7 on-off inputs, 1 high-speed pulse input, can extend 3 inputs*1 2 programmable AI: AI1: voltage -10 ~ 10V A12: voltage 0 ~ 10V or current 0/4~20mA | |

| Output terminals | 1 programmable open collector output: 1 analog output (open collector output or high-speed pulse output), can extend 1 output×1 1 relay output, can extend 1 output×1 2 analog output: 0/4~20mA or 0~10V | ||

| Communication Terminal×2 | Offer RS485 communication interface, support MODBUS-RTU communication protocol | ||

Model Selection

KE600 Variable Frequency Drive Types and Technical Parameters

| Type | Voltage Classes | Matched Motor | Rated Input Current (A) | Rated Output Current (A) | |

| (V) | kW | HP | |||

| KE600-1R5G-T2 | 220 | 1.5 | 2 | 7.7 | 7 |

| KE600-2R2G-T2 | 220 | 2.2 | 3 | 10.5 | 9 |

| KE600-004G-T2 | 220 | 4 | 5 | 18 | 17 |

| KE600-5R5G-T2 | 220 | 5.5 | 7.5 | 26 | 25 |

| KE600-7R5G-T2 | 220 | 7.5 | 10 | 35 | 32 |

| KE600-011G-T2 | 220 | 11 | 15 | 46.5 | 45 |

| KE600-015G-T2 | 220 | 15 | 20 | 62.5 | 60 |

| KE600-018G-T2 | 220 | 18.5 | 25 | 76 | 75 |

| KE600-022G-T2 | 220 | 22 | 30 | 92 | 91 |

| KE600-030G-T2 | 220 | 30 | 40 | 113 | 112 |

| KE600-037G-T2 | 220 | 37 | 50 | 157 | 150 |

| KE600-045G-T2 | 220 | 45 | 60 | 180 | 176 |

| KE600-055G-T2 | 220 | 55 | 75 | 214 | 210 |

| KE600-075G-T2 | 220 | 75 | 100 | 307 | 304 |

| Type | Voltage Classes | Matched Motor | Rated Input Current (A) | Rated Output Current (A) | |

| (V) | kW | HP | |||

| KE600-1R5G-T4 | 380 | 1.5 | 2 | 5 | 3.8 |

| KE600-2R2G-T4 | 380 | 2.2 | 3 | 7 | 6 |

| KE600-004G-T4 | 380 | 4 | 5 | 10 | 9 |

| KE600-5R5G-T4 | 380 | 5.5 | 7.5 | 15 | 13 |

| KE600-7R5G-T4 | 380 | 7.5 | 10 | 20 | 17 |

| KE600-011G-T4 | 380 | 11 | 15 | 26 | 25 |

| KE600-015G-T4 | 380 | 15 | 20 | 35 | 32 |

| KE600-018G-T4 | 380 | 18.5 | 25 | 38 | 37 |

| KE600-022G-T4 | 380 | 22 | 30 | 46 | 45 |

| KE600-030G-T4 | 380 | 30 | 40 | 62 | 60 |

| KE600-037G-T4 | 380 | 37 | 50 | 76 | 75 |

| KE600-045G-T4 | 380 | 45 | 60 | 92 | 90 |

| KE600-055G-T4 | 380 | 55 | 75 | 150 | 110 |

| KE600-075G-T4 | 380 | 75 | 100 | 157 | 150 |

| KE600-090G-T4 | 380 | 90 | 125 | 180 | 176 |

| KE600-110G-T4 | 380 | 110 | 150 | 214 | 210 |

| KE600-132G-T4 | 380 | 132 | 175 | 256 | 253 |

| KE600-160G-T4 | 380 | 160 | 210 | 307 | 304 |

| KE600-185G-T4 | 380 | 185 | 250 | 350 | 340 |

| KE600-200G-T4 | 380 | 200 | 260 | 385 | 377 |

| KE600-220G-T4 | 380 | 220 | 300 | 430 | 423 |

| KE600-250G-T4 | 380 | 250 | 330 | 468 | 465 |

| KE600-280G-T4 | 380 | 280 | 370 | 525 | 520 |

| KE600-315G-T4 | 380 | 315 | 420 | 590 | 585 |

| KE600-350G-T4 | 380 | 350 | 470 | 665 | 650 |

| KE600-400G-T4 | 380 | 400 | 530 | 785 | 720 |

| KE600-450G-T4 | 380 | 450 | 600 | 880 | 820 |

| KE600-500G-T4 | 380 | 500 | 660 | 960 | 900 |

| KE600-560G-T4 | 380 | 560 | 750 | 1050 | 1000 |

| KE600-630G-T4 | 380 | 630 | 840 | 1130 | 1100 |

| Type | Voltage Classes | Matched Motor | Rated Input Current (A) | Rated Output Current (A) | |

| (V) | kW | HP | |||

| KE600-015G-T6 | 660 | 15 | 20 | 21 | 19 |

| KE600-018G-T6 | 660 | 18.5 | 25 | 28 | 22 |

| KE600-022G-T6 | 660 | 22 | 30 | 35 | 28 |

| KE600-030G-T6 | 660 | 37 | 40 | 40 | 35 |

| KE600-037G-T6 | 660 | 37 | 50 | 47 | 45 |

| KE600-045G-T6 | 660 | 45 | 60 | 55 | 52 |

| KE600-055G-T6 | 660 | 55 | 75 | 65 | 63 |

| KE600-075G-T6 | 660 | 75 | 100 | 90 | 86 |

| KE600-090G-T6 | 660 | 90 | 105 | 100 | 98 |

| KE600-110G-T6 | 660 | 110 | 130 | 130 | 121 |

| KE600-132G-T6 | 660 | 132 | 175 | 170 | 150 |

| KE600-160G-T6 | 660 | 160 | 210 | 200 | 175 |

| KE600-185G-T6 | 660 | 185 | 250 | 210 | 195 |

| KE600-200G-T6 | 660 | 200 | 260 | 235 | 215 |

| KE600-220G-T6 | 660 | 220 | 300 | 257 | 245 |

| KE600-250G-T6 | 660 | 250 | 330 | 265 | 260 |

| KE600-280G-T6 | 660 | 280 | 370 | 305 | 300 |

| KE600-315G-T6 | 660 | 315 | 420 | 350 | 330 |

| KE600-350G-T6 | 660 | 350 | 470 | 382 | 374 |

| KE600-400G-T6 | 660 | 400 | 530 | 435 | 410 |

| KE600-450G-T6 | 660 | 450 | 600 | 490 | 465 |

| KE600-500G-T6 | 660 | 500 | 660 | 595 | 550 |

| KE600-560G-T6 | 660 | 560 | 745 | 610 | 590 |

| KE600-630G-T6 | 660 | 630 | 840 | 700 | 680 |

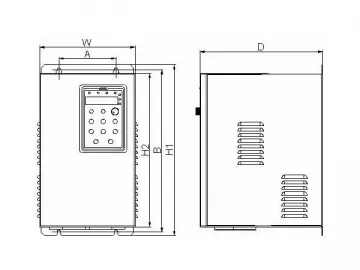

Overall Dimensions

KE600 Three Phase 380V Variable Frequency Drive Dimensions

0.75~5.5kW

7.5~30kW

37~200kW (including standard machine with power ranging from 90kW to 200 kW)

| Power Range (kW) | W | H | D | A | B |

| 1.5~4 | 135 | 240 | 173 | 122.6 | 229 |

| Power Range (kW) | W | H1 | H2 | D | A | B |

| 7.5~15 | 200 | 330 | 300 | 188.8 | 90 | 317 |

| 18.5~30 | 255 | 440 | 403 | 229 | 140 | 423.6 |

| Power Range (kW) | W | H1 | H2 | D | A | B |

| 37~45 | 280 | 570 | 521 | 269 | 190 | 552 |

| 55~75 | 320 | 600 | 552 | 330 | 230 | 582 |

| 90~110 | 320 | 715 | 662 | 356 | 230 | 695.5 |

| 132~200 | 480 | 790 | 725 | 385 | 360 | 768 |

Applications

With excellent performance, KE600 close loop vector control variable frequency drive enjoys a wide range of applications.

Injection Molding Industry

Lifting Appliances and Belt Conveyors

Machine Equipment

Textile Industry Metal Processing Industry

Medical and Pharmaceutical Industry

Other High-End Application Occasions Such as Food Processing Industry

Links:https://globefindpro.com/products/77710.html

-

28mm PM Stepper Motor with Captive Shaft Actuator

28mm PM Stepper Motor with Captive Shaft Actuator

-

Wiper Arm

Wiper Arm

-

Eco-Friendly Fluorescent Pigment Paste

Eco-Friendly Fluorescent Pigment Paste

-

Wiper Motor

Wiper Motor

-

QY660L RH750 Tire Changer

QY660L RH750 Tire Changer

-

Eco-Friendly Water-based Pigment Paste

Eco-Friendly Water-based Pigment Paste

-

Wiper Blade

Wiper Blade

-

QY301OPS,QY302OPS Air Tire Inflator

QY301OPS,QY302OPS Air Tire Inflator

-

76 Series Alcohol-Soluble Letterpress Printing Ink for Plastic Film

76 Series Alcohol-Soluble Letterpress Printing Ink for Plastic Film

-

D Series Eco-Friendly Pigment Paste for Textile Dyeing

D Series Eco-Friendly Pigment Paste for Textile Dyeing

-

Digital Keypad (for Inverter Operation)

Digital Keypad (for Inverter Operation)

-

CD Series Eco-Friendly Pigment Paste for Textile One-Bath Dyeing

CD Series Eco-Friendly Pigment Paste for Textile One-Bath Dyeing