TQ Series Casing Tong

Overview

The TQ series casing tong is perfectly designed to quickly handle your casing requirements in oil or mine field. It boasts lightweight design, high operation efficiency, as well as high safety and reliability, saving labor intensi and enhancing threaded connection quality.

This open-throat power tong adopts oscillating double-jaw tong head to guarantee reliable spider clamping. It can be configured with torque meter, and also enables computerized monitoring and management for operation pressure and torque. Currently, this casing tong has obtained multiple national patents, complying with SY/T5074 standard and API 7K specifications.

Remarkable Features

1. One-piece open tong head boasts high strength and rigidity, and thereby this casing running tool can rapidly and easily enter into or withdraw from working position.

2. Thanks to oscillating double-jaw tong head design, dismounting turns to be easier. Meanwhile, optimal scale design makes clamping more secure.

3. Our casing tong makes use of brake band for braking, characterized by large braking torque, and easy for operation, maintenance and replacement.

4. Unique supporting structure tremendously improves strength and stiffness of large gear wheel.

5. This oil well drilling outfit utilizes double-row planetary reduction gear to realize three-gear operation. In the meantime, pneumatic tube clutch capable of gear shifting without stop effectively prevents casing tong from being stuck by jaws. Thus, motor stop and low efficiency are avoided.

6. Because of adoption of special craft and structure, torque of gear motor is increased by about 20%.

7. The casing of our tong is made from 16Mn (low-alloy high-tensile structural steel) material. All jaws are fabricated via precision casting craft, featured by elegant contour and high strength.

8. Our casing tong is also engineered with a hydraulic load moment indicator and interface, convenient for computer management.

| Model | TQ178-16 | TQ178-16Y | TQ340-35 | TQ340-35Y | TQ356-55 | TQ356-55Y | TQ508-70Y | TQ340-85Y | ||

| Size range | mm | 101.6-178 | 101.6-178 | 114.3-340 | 114.3-340 | 114.3-356 | 114.3-356 | 114.3-340 | 114.3-340 | |

| inch | 4-7 | 4-7 | 41/2-133/8 | 41/2-133/8 | 41/2-14 | 41/2-14 | 95/8-20 | 41/2-133/8 | ||

| Max. Pressure | MPa | 18 | 16 | 18 | 20 | 16.6 | 20 | 20 | 18 | |

| psi | 2610 | 2320 | 2610 | 2900 | 2400 | 2900 | 2900 | 2610 | ||

| Flow Rating | L/min. | 110-160 | 110-160 | 110-160 | 110-170 | 110-140 | 110-170 | 110-170 | 110-170 | |

| gpm | 29.3-42.7 | 29.3-42.7 | 29.3-42.7 | 29.3-45.4 | 29.3-37.3 | 29.3-45.4 | 29.3-45.4 | 29.3-45.4 | ||

| Air pressure | MPa | 0.5-0.9 | - | 0.5-0.9 | - | 0.5-0.9 | - | - | - | |

| psi | 72-130 | 72-130 | 72-130 | |||||||

| Max. torque | High gear | kN·m | 2.4-3 | 2.4-3 | 2.5-3 | 3.5-6 | 3.8-4.2 | 7 | 8.4-10.7 | 12.5-14 |

| ft·lbf | 1770-2210 | 1770-2210 | 1844-2210 | 2580-4425 | 2800-3100 | 5160 | 6190-7890 | 9220-10325 | ||

| Medium gear | kN·m | - | - | 6.0-7.5 | - | - | - | - | - | |

| ft·lbf | 4425-5530 | |||||||||

| Low gear | kN·m | 14.5-17.5 | 16-19 | 32-40 | 22-37 | 53-58 | 57 | 48.9-70.5 | 85-90 | |

| ft·lbf | 10694-12900 | 11060-13270 | 23600-29500 | 16225-27285 | 39080-42775 | 42030 | 37244-52000 | 62690-66375 | ||

| Speed | High gear | rpm | 54-79 | 50-72 | 60-86 | 50-90 | 56-70 | 39.4-60.9 | 26-43.6 | 30-45 |

| Medium gear | rpm | - | - | 21-30 | - | - | - | - | - | |

| Low gear | rpm | 9-13.1 | 9-13 | 3.6-5.3 | 8-14 | 4-5 | 4.8-7.4 | 4-6.6 | 3.2-5 | |

| Lifting distance | mm | - | - | - | 622 | - | 615 | 622 | 622 | |

| inch | 24.5 | 24.2 | 24.5 | 24.5 | ||||||

| Size | mm | 1450×760×740 | 1500×760×800 | 1580×900×880 | 1580×900×1060 | 1770×960×850 | 1770×960×780 | 2080×1280×760 | 1995×1150×680 | |

| inch | 57×30×29.1 | 59×30×34.6 | 62.2×35.4×34.6 | 62.2×35.4×34.6 | 69.7×37.8×33.5 | 69.7×37.8×30.7 | 82×50.4×30 | 78.5×45.3×26.8 | ||

| Weight | kg | 580 | 560 | 780 | 760 | 1150 | 1100 | 1550 | 1700 | |

| lb | 1280 | 1230 | 1720 | 1670 | 2530 | 2420 | 3410 | 3740 | ||

Links:https://globefindpro.com/products/77992.html

-

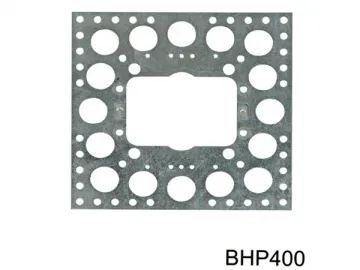

Plaster Wallboard Bracket

Plaster Wallboard Bracket

-

Double 3 Pin Surface Mounted Outlet

Double 3 Pin Surface Mounted Outlet

-

Active/Neutral Link

Active/Neutral Link

-

Single 3 Pin Surface Mounted Outlet

Single 3 Pin Surface Mounted Outlet

-

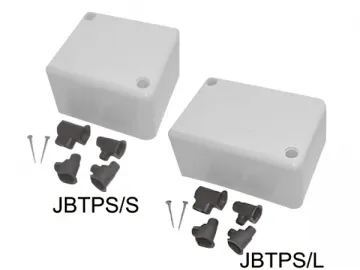

Junction Box with Connectors

Junction Box with Connectors

-

Flat Bracket with Nails

Flat Bracket with Nails

-

TB Series Casing Tong with Clincher Back-Up

TB Series Casing Tong with Clincher Back-Up

-

Hydraulic Lifting Platform

Hydraulic Lifting Platform

-

IP56 Junction Box with Screw-Down Cover

IP56 Junction Box with Screw-Down Cover

-

Three Phase 4 Pin Socket

Three Phase 4 Pin Socket

-

YXM Series Rotary Catheads

YXM Series Rotary Catheads

-

ZTQ Series Dual-purpose Power Tong

ZTQ Series Dual-purpose Power Tong