35kV XLPE Insulated (Flame-Retardant) Power Cable

Depending on the flame retardant property, the 35kV XLPE insulated power cable is divided into two types, common type and flame-retardant type.

For the common type, it adopts advanced photo cross-linking and three layer co-extrusion technologies, so it shows the advantages of outstanding reliability, high degree of crosslinking, good resistance to high temperature, etc. Based on these features, it is suitable for power system where the conductor works at 90℃. On the other hand, the flame-retardant type uses protective jacket that is resistant to fire, and flame retardant is added to the materials which ensures the excellent fire proofing property of the cable. So, this product is applied for the places that have strict flame-retardant requirement.

Model Explanation

| Model | Descriptions | Applications | |

| Cu Core | Al Core | ||

| YJV | YJLV | XLPE insulated and PVC sheathed power cable | It can be laid in outdoor tunnel, cable duct, reinforced concrete pipeline and loose soil. It can not bear external mechanical force, but a certain tensile force is applicable. |

| YJV22 | YJLV22 | XLPE insulated, steel tape armored and PVC sheathed power cable | It is laid underground, and it can stand external mechanical force. However, big tensile force should not be applied. |

| YJV32 | YJLV32 | XLPE insulated, thin steel wire armored and PVC sheathed power cable | It is laid in tunnels, mines and indoor places, and mechanical force and quite big tensile force are both applicable. |

| YJV42 | YJLV42 | XLPE insulated, thick steel wire armored and PVC sheathed power cable | It is suitable for tunnel, mine, vertical place and indoor place. In addition, big tensile force and external mechanical force won't destroy this product. |

Note:

1. The models also contain flame-retardant type.

2. The single core type should not be laid in iron pipes.

3. Halogen free low-smoke power cable is also provided on customer's request.

4. When signing the contract, the flame retardant type must be specified. For example, if type A is preferred, please add "A" to the end of "ZR", forming "ZRA", and A is usually used in places where the flame-retardant property is highly required. B and C follow the same rule. In addition, if there is no letter after "ZR", the cable will be produced following "ZRC".

| Model | No. of Core | Rated Voltage (kV) | |||||

| Cu Core | Al Core | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 26/35 18/30 18/20 | |

| Nominal Cross Section (mm2) | |||||||

| YJV YJY YJV22 YJV32 YJV33 YJV42 YJV43 | YJLV YJLY YJLV22 YJLV32 YJLV33 YJLV42 YJLV43 | 1 | 10-1200 10-1200 10-1200 10-1200 10-1200 10-1200 10-1200 | 16-1200 16-1200 16-1200 16-1200 16-1200 16-1200 16-1200 | 25-1200 25-1200 25-1200 25-1200 25-1200 25-1200 25-1200 | 35-1200 35-1200 35-1200 35-1200 35-1200 35-1200 35-1200 | 50-1200 50-1200 50-1200 50-1200 50-1200 50-1200 50-1200 |

| YJV YJY YJV22 YJV23 YJV32 YJV33 YJV42 YJV43 | YJLV YJLY YJLV22 YJLV23 YJLV32 YJLV33 YJLV42 YJLV43 | 2 | 10-500 10-500 10-500 10-500 10-500 10-500 10-500 10-500 | 16-500 16-500 16-500 16-500 16-500 16-500 16-500 16-500 | 25-500 25-500 25-500 25-500 25-500 25-500 25-500 25-500 | 35-500 35-500 35-500 35-500 35-500 35-500 35-500 35-500 | 50-500 50-500 50-500 50-500 50-500 50-500 50-500 50-500 |

Note:

1. These models contain three types, which are flame-retardant type, low-halogen low-smoke type, as well as halogen free low-smoke type.

2. Non-magnetic material or magnetic loss reducing structure should be applied to armor the single core cable.

Technical Parameters

| Nominal Cross Section (mm2) | Max. DC Resistance of Conductor at 20℃ (Ω/km) | Nominal Cross Section (mm2) | Max. DC Resistance of Conductor at 20℃ (Ω/km) | Nominal Cross Section (mm2) | Max. DC Resistance of Conductor at 20℃ (Ω/km) | |||

| Cu Core | Al Core | Cu Core | Al Core | Cu Core | Al Core | |||

| 1.5 2.5 4 6 10 16 25 - | 12.1 7.41 4.61 3.08 1.83 1.15 0.727 - | - - - - 3.08 1.91 1.20 - | 35 50 70 95 120 150 185 - | 0.524 0.387 0.268 0.193 0.153 0.124 0.0991 - | 0.868 0.641 0.443 0.320 0.253 0.206 0.164 - | 240 300 400 500 630 800 1000 1200 | 0.0754 0.0601 0.0470 0.0366 0.0283 0.0221 - - | 0.125 0.100 0.0778 0.0605 0.0469 0.0367 0.0291 0.0247 |

Qualifications

| No. | Item | Rated Voltage U0/U (kV) | |||||||

| 1.8/3 | 3.6/6 | 6/6 6/10 | 8.7/10 8.7/15 | 12/20 | 18/20 18/30 | 21/35 | 26/35 | ||

| 1 | DC Resistance of Conductor (Ω/km) | See the table above | |||||||

| 2 | Partial Discharge Test: Max. Value at 1.73U0 (pC) | 10 | 10 | ||||||

| 3 | 5 Minutes Power Frequency Withstand Voltage Test (kV) | 6.5 | 12.5 | 21 | 30.5 | 42 | 63 | 73.5 | 91 |

| 4 | 4 Hours Power Frequency Test (kV) | 7.2 | 14.4 | 24 | 35 | 48 | 72 | 84 | 104 |

| 5 | Hot Set Test (200℃, 15min, 20N/cm): Max. Elongation Rate / Max. Permanent Elongation Rate After Cooling (%) | 175 / 15 | |||||||

| 6 | Max. Partial Discharge at 1.73U0 After Three Times of Bending and Heat Cycling (pC) | 5 | 5 | ||||||

| 7 | Max. Tan Delta at U0 and Room Temperature Max. Tan Delta at 0.5-2U0 | ... | ... | 40×10-4 20×10-4 | ... | ||||

| 8 | Max. Tan Delta at Room Temperature Max. Tan Delta When Heated to Long Time Working Temperature (90℃) | ... | ... | 40×10-4 80×10-4 | 10×10-4 | ||||

| 9 | Flame Retardant Test | It meets the standards of GB/T 18380.3-2008 and IEC332-2C. | |||||||

Note: No. 113 are routine tests before leaving factory, No. 4-5 are sample tests, and No. 6-9 are type testing items.

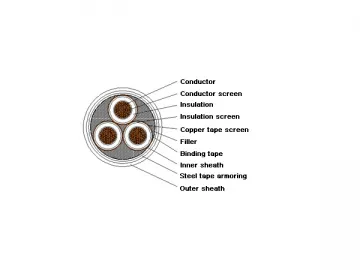

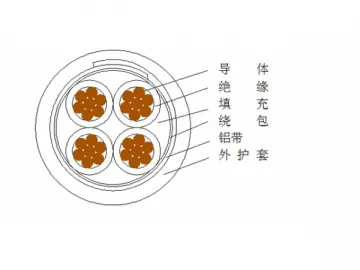

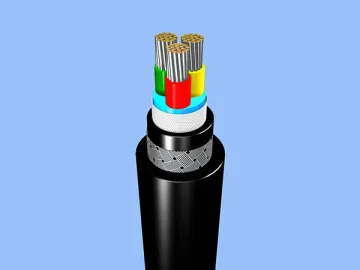

Structures

| Medium voltage single core XLPE insulated and PVC sheathed (flame-retardant) power cable | Medium voltage single core XLPE insulated and stainless steel tape armored (flame-retardant) power cable |

| Medium voltage single core XLPE insulated, steel wire armored, and PVC sheathed (flame-retardant) power cable | Medium voltage XLPE insulated and PVC sheathed (flame-retardant) power cable |

| Medium voltage XLPE insulated, steel tape armored and PVC sheathed (flame-retardant) power cable with semi-conducting tape | Medium voltage XLPE insulated, steel tape armored and PVC sheathed (flame-retardant) power cable without semi-conducting tape |

Standards

GB/T 12706-2008: Power cables with extruded insulation and their accessories for rated voltage from 1kV (Um=1.2kV) up to 35kV (Um=40.5kV), IEC 60502-2005

Applications

This 35kV XLPE insulated power cable is used for transmission and distribution of high voltage power lines with rated voltage of 35kV.

Application Properties

The maximum rated temperature for the conductor is 90℃. However, its temperature should not exceed 250℃ during short circuit, and the short circuit should not last for 5 seconds or longer time. On the other hand, when laying the cable, the ambient temperature should not be lower than 0℃, otherwise, preheating is needed.

Minimum bending radius: 15 times of overall cable diameter for single core type, and 10 times of overall cable diameter for multi-core type.

Outer Diameter and Weight

3.6/6kV single core XLPE insulated power cable

6/6kV 6/10kV single core XLPE insulated power cable

8.7/10kV 8.7/15kV single core XLPE insulated power cable

18/20kV 18/30kV single core XLPE insulated power cable

21/35kV single core XLPE insulated power cable

26/35kV single core XLPE insulated power cable

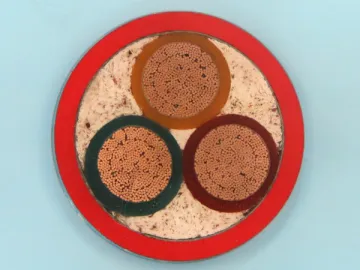

3.6/6kV three core XLPE insulated power cable

6/6kV three core XLPE insulated power cable

8.7/10kV 8.7/15kV three core XLPE insulated power cable

12/20kV three core XLPE insulated power cable

26/35kV three core XLPE insulated power cable

Related Names

Flame Resistant Power Cable Supplier | Industrial Electrical Cable | Medium Voltage Power Product

Links:https://globefindpro.com/products/78355.html

-

Shipboard Wire

Shipboard Wire

-

Plastics Insulated and Sheathed Control Cable

Plastics Insulated and Sheathed Control Cable

-

Chemical Corrosion Resistant Power Cable

Chemical Corrosion Resistant Power Cable

-

Single-Phase AC Electric Railway 27.5kV XLPE Insulated Power Cable

Single-Phase AC Electric Railway 27.5kV XLPE Insulated Power Cable

-

Offshore Power Cable

Offshore Power Cable

-

XLPE Insulation Shipboard VFD Power Cable

XLPE Insulation Shipboard VFD Power Cable

-

1kV/3kV PVC Insulated (Flame-Retardant) Power Cable

1kV/3kV PVC Insulated (Flame-Retardant) Power Cable

-

KSJZ1500 Pelletizing Line

KSJZ1500 Pelletizing Line

-

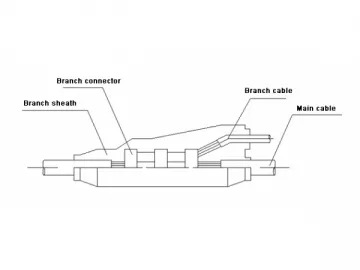

Branch Power Cable

Branch Power Cable

-

0.6/1kV NBR Soft Power Cable

0.6/1kV NBR Soft Power Cable

-

Offshore Communication Cable

Offshore Communication Cable

-

Silicon Rubber Insulated and Sheathed Power Cable

Silicon Rubber Insulated and Sheathed Power Cable