Material Hoist

Automatic rope feeding function is one of the unique features of the material hoist produced by Little Swan. During operation, you only need to insert the steel rope into the rope inlets. Also, the all-aluminum box formed by the gravity die casting technology is hard to be damaged and it ensures no oil leakage. High precision, high strength transmission parts are used, which extend the service life of the material handling equipment. In addition, specialized assembly process and high precision assembly technology effectively reduce the noise level of the material hoist during its operation.

The rated lifting weight of our material hoist is 600 kg and the maximum lifting height can reach 100 m. This lifting equipment can be used for the vertical transport of materials in the construction of high-rise buildings, bridges, and chimneys. Additionally, the hoisting equipment can work together with the suspended access platform to safely, reliably and dramatically improve the efficiency of construction.

Technical Parameters

| Type | QP600 |

| Rated Lifting Weight (kg) | 600 |

| Lifting Speed (m/min) | 12.5 |

| Maximum Lifting Height (m) | 100 |

| Maximum Extension for the Front Beam of Suspended Mechanism (mm) | 2000 |

| Hoist Type | LTD630 |

| Motor Power of Hoist (kW) | 1.8 |

| Safety Lock Type | LSL30 |

| Steel Wire Rope Type | 4 × 31SW FC-8.3 |

| Propulsive Force of Electric Handspike (kg) | 300 |

| Distance for expand and contract of Electric Handspike (mm) | 1000 |

| Total Weight (kg) | 490 |

| Counterweight (kg) | 500 |

Links:https://globefindpro.com/products/78369.html

-

HJJ Industrial Mixer

HJJ Industrial Mixer

-

TLSS Screw Conveyor

TLSS Screw Conveyor

-

FZLJ Fertilizer Pellet Mill

FZLJ Fertilizer Pellet Mill

-

Construction Hoist

Construction Hoist

-

1-6t/h Hammer Mill

1-6t/h Hammer Mill

-

TCXT Magnetic Separator

TCXT Magnetic Separator

-

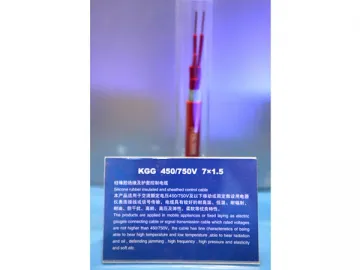

Marine High Temperature Cable

Marine High Temperature Cable

-

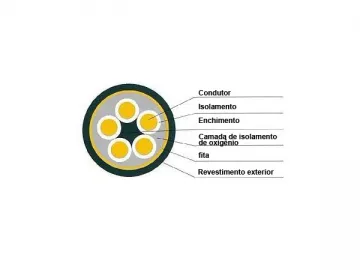

Flame Retardant Power Cables with Fire Proof Layer

Flame Retardant Power Cables with Fire Proof Layer

-

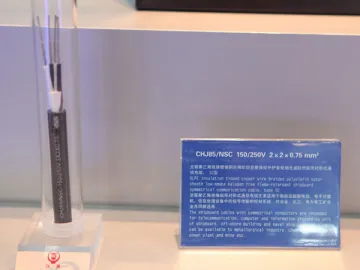

XLPE Insulation Flame Retardant Shipboard Symmetrical Communication Cable without Inner Sheath

XLPE Insulation Flame Retardant Shipboard Symmetrical Communication Cable without Inner Sheath

-

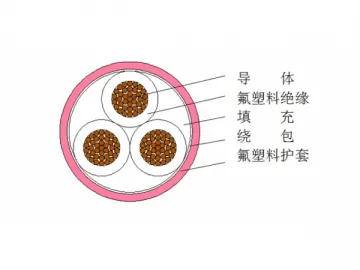

Fluoroplastics Insulated Heat-Resistant Power Cable

Fluoroplastics Insulated Heat-Resistant Power Cable

-

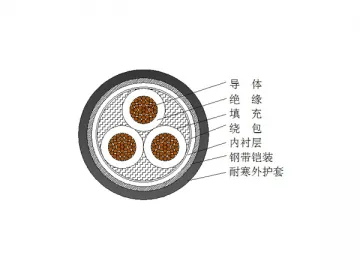

XLPE Insulated Cold-Resistant Power Cable

XLPE Insulated Cold-Resistant Power Cable

-

XLPE Insulation Shipboard VFD Power Cable

XLPE Insulation Shipboard VFD Power Cable