Filter Accessories

Filter Accessories

Our filter accessories mainly include centrifugal fan and dust collection hopper, and please refer to the following paragraphs for more detailed information.

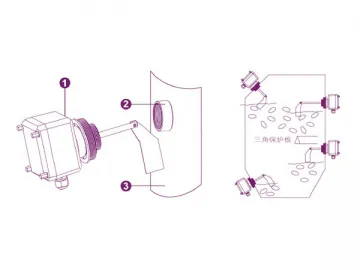

1. Centrifugal Fan

FS series centrifugal fan is especially designed for CH silo venting filter. When compared with similar products, it offers higher wind pressure without reducing air volume, and this is very beneficial for dust collection. This blower is available in different models to work with silo venting filters in different diameters, and the air volume varies from 500~5000m3/h.

Technical Data

| Diameter of silo venting filter (mm) | Centrifugal fan power (kW) | |||||

| 0.75 | 1.1 | 2.2 | 3 | 4 | 5.5 | |

| 400 | √ | √ | × | × | × | × |

| 600 | √ | √ | √ | × | × | × |

| 800 | √ | √ | √ | √ | × | × |

| 1000 | √ | √ | √ | √ | √ | √ |

2. Dust Collection Hopper

a. Tangential Inlet Dust Hopper

As the name implies, the tangential inlet dust hopper has a tangential inlet which directs dirty gas stream flow along the hopper wall after entering into the hopper. So, the flow speed is reduced, and some granules drop down into the tapered bucket directly due to the friction with hopper wall, thus cutting down the dust concentration near filter elements. Moreover, there is a tapered plate on the top of dust hopper to offer better result.

Depending on the abovementioned features, this dust hopper alleviates the working load of filter elements, thus extending their life span.

b. Dust Hopper with Turbulator

At the air inlet, there is a turbulator used to change the direction of dirty gas stream and lower the velocity of dust. So, the filter element exhibits a prolonged service life because its working load is reduced.

In general, this dust hopper is applicable for places where the dust concentration is high, the wind speed is fast, and the materials are dry and abrasive. In particular, it is especially suitable for pneumatic conveying systems.

c. Dust Hopper with Turbulator and Air Hammer

This dust hopper is outfitted with a turbulator and an air hammer, as indicated by its name. The air hammer is designed to exert impact force on the turbulator at fixed time intervals so as to remove materials that have been attached to the turbulator, otherwise the turbulator may get stuck.

This dust hopper fits for conditions where the dust concentration is high, the airflow velocity is fast, and the gas stream contains water or other adhesive substances.

d. Multi-Inlet Dust Hopper

The multi-inlet dust hopper has 2-4 air inlets, making it extremely suitable for places where there are several dust sources but the dust concentration and air volume of each dust source are not too high. In this regard, our product cuts down the number of dedusting equipment required for a specific location, thus saving your money.

Links:https://globefindpro.com/products/78414.html

-

ZLP630B Suspended Platform

ZLP630B Suspended Platform

-

Filter Cartridge, Filter Bag

Filter Cartridge, Filter Bag

-

Pressure Relief Valve

Pressure Relief Valve

-

Steel Suspended Platform

Steel Suspended Platform

-

Horizontal Bag Filling and Sealing Machine

Horizontal Bag Filling and Sealing Machine

-

Vibrating Bin Aerator

Vibrating Bin Aerator

-

Butterfly Valve for Powder

Butterfly Valve for Powder

-

Vibrant Silo Venting Filter

Vibrant Silo Venting Filter

-

Aeration Nozzle

Aeration Nozzle

-

Filter Cleaning System

Filter Cleaning System

-

Rotary Level Indicator

Rotary Level Indicator

-

GB Standard LPG Cylinder

GB Standard LPG Cylinder