Filter Cleaning System

Filter Cleaning System

Why use a filter cleaning system?

The filter cleaning system is an indispensable part if a silo venting filter needs to work continuously, because dust and powders will gradually accumulate on the surface of filter elements since the start of dedusting, thus decreasing venting capacity of the filter while increasing flow resistance simultaneously. Given this, powders and dust on the filter element must be removed to recover normal venting capacity and protect these filter elements against damage caused by high pressure. That is why a filter cleaning system is very necessary for dust collectors.

How does it work?

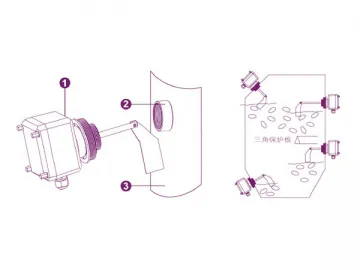

Our reverse pulse cleaning system, also known as reverse jet cleaning system, is mainly composed of a reverse pulse controller, an air storage tank, pulse solenoid valves, blowing pipes and Venturi tubes. The controller automatically switches solenoid valves between on and off states, and then compressed air in the storage tank is blown into filter elements through blow pipes and Venturi tubes. As we know, compressed air is a high-pressure gas that will expand under this condition, and the impact force generated during gas expansion will inflate filter elements outwards, thus pulverizing and removing accumulated dust or powder. In this way, filter elements are recovered for further use.

In addition, this air jet cleaning system offers the best solution for places where the silo venting filter needs to work frequently or for a long time, as well as places where the dust concentration is pretty high.

What is the function of each component?

1. Reverse Pulse Controller

The reverse pulse controller is the most important part for a filter cleaning system, and it is used to switch on or off the solenoid valves. This controller is controlled by a single-chip microcomputer automatically, while the pulse width and pulse interval can be adjusted within 0.1-0.3s and 5-90s respectively, thereby enabling the dust collector to suit for various dust concentrations, air volumes and cleaning requirements. In addition, the control panel is equipped with buttons to facilitate operation, and parameters are revealed in a digital way.

If necessary, a differential pressure control unit could be integrated to our reverse pulse controller. It makes use of a specialized pressure sensor to detect the pressure difference between two sides (inside and outside) of a filter element, and real-time displays this value. When the detected pressure difference reaches up to the preset value, this control unit will start up the filter cleaning system automatically to dislodge accumulated dust cakes. When the detected pressure difference drops below the preset value, our filter cleaning system will stop automatically to save compressed air. This solution is suitable for places where the dust concentration is low but long-time cleaning is required.

Our reverse pulse controller has a default function called 10-minute delay cleaning, which means after the controller is switched off (but power supply should be on), an extra 10-minute-long cleaning process will be conducted automatically to prevent dust from accumulating on the surface of filter element after the dust collector has stopped. But, this function is not valid when the abovementioned differential pressure control unit is adopted.

Feature Summary

1. Automatically controlled by a 16-bit single chip microcomputer

2. Application-specific integrated circuit (ASIC) for stable performance

3. Digital LED for intuitional data display

4. Parameter set by buttons

5. 10-minute delay cleaning function

6. Integrated pressure sensor for real-time pressure difference checking

2. Pulse Solenoid Valve

These pulse solenoid valves are especially designed for silo venting filter, and they are characterized by large flow, low resistance and long service life (over 1 million times for the diaphragm). The solenoid coil is DC24V type, AC220V type or specialized anti-explosion type.

3. Air Storage Tank

For our filter cleaning system, the air storage tank is manufactured from industrial grade aluminum alloy profiles via precision machining, assembling and testing processes to ensure its excellent tightness. The finished storage tank is a lightweight container with beautiful appearance, and it is resistant to corrosion.

4. Air Distribution Box and Venturi TubeThe air distribution box is made of high-strength plastics, and it delivers compressed air that is released from solenoid valves into every filter element evenly with the help of blow pipes. On the other hand, Venturi tubes, designed to increase fluid velocity, helps to increase the flow speed of compressed air, thus effectively cleaning all the filter elements and prolonging their service life.

Links:https://globefindpro.com/products/78410.html