ASTM A519 Seamless Steel Pipe for Mechanical Engineering

The ASTM A519 seamless steel pipe is applicable for mechanical engineering. It can be used in the transportation of steam, water, gas and so on. Its ultimate processing method of plastic deformation can be hot rolling or cold rolling. The mechanical tubing is manufactured from cast-in ingots or has received strand casting treatment.

When different grades of steel are successively strand cast, it is necessary to identify the corresponding transition material. Usually made of hot-worked steel, the seamless steel pipe does not contain any welded seam. To achieve desired shape, dimension and properties, the liquid transfer pipe may undergo hot rolling treatment. Our specialized persons may carry out heat analysis to identify the percentages of specified elements. Before shaped, the semi-finished product will be coated with an oil layer, so the seamless steel pipe does not readily rust.

Parameters

1. Standard: ASTM A519

2. Steel grade: 1010, 1020, 1026, 1045

3. Delivery condition: Hot rolling

4. Outer diameter: 70MM-610MM,

5. Wall thickness: 6MM-35MM

6. Tolerance: According to standard

7. Length: Customization

8. Certificate: EN 10204/3.1

Chemical Composition (Heat Analysis)%

| Steel grade | Delivery condition | C | Si | Mn | P (max.) | S (max.) |

| 1010 | Hot rolling | 0.08-0.13 | - - | 0.30-0.60 | 0.040 | 0.050 |

| 1020 | Hot rolling | 0.18-0.23 | - - | 0.30-0.60 | 0.040 | 0.050 |

| 1026 | Hot rolling | 0.22-0.28 | - - | 0.60-0.90 | 0.040 | 0.050 |

| 1045 | Hot rolling | 0.43-0.50 | - - | 0.60-0.90 | 0.040 | 0.050 |

Mechanical Property

| Steel grade | Min. yield strength | Min. tensile strength | Min. elongation (%) |

| Mpa | Mpa | ||

| 1010 | - - | - - | - - |

| 1020 | 221 | 345 | 25 |

| 1026 | - - | - - | - - |

| 1045 | 310 | 517 | 15 |

Links:https://globefindpro.com/products/78936.html

-

EN 10210 Hot Rolled Steel Structural Pipe

EN 10210 Hot Rolled Steel Structural Pipe

-

Hydrocortisone

Hydrocortisone

-

EN 10297 Seamless Steel Tube for Mechanical Engineering

EN 10297 Seamless Steel Tube for Mechanical Engineering

-

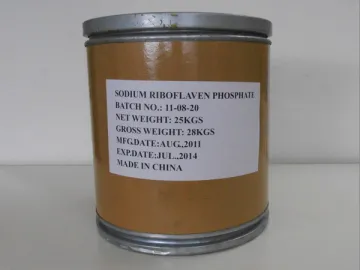

Riboflavin-5-Phosphate Sodium

Riboflavin-5-Phosphate Sodium

-

Astragalus Extract

Astragalus Extract

-

API 5L PSL1&PSL2 Steel Pipe

API 5L PSL1&PSL2 Steel Pipe

-

Hydrocortisone Acetate

Hydrocortisone Acetate

-

ASME SA53/ASTM A53 Seamless Steel Pipe

ASME SA53/ASTM A53 Seamless Steel Pipe

-

API 5L Corrosion Resistant Steel Pipe

API 5L Corrosion Resistant Steel Pipe

-

Trimethoprim(TMP)

Trimethoprim(TMP)

-

Nilestriol

Nilestriol

-

API 5CT Oilfield Casing and Tubing

API 5CT Oilfield Casing and Tubing