EN 10297 Seamless Steel Tube for Mechanical Engineering

Based on EN 10297 standard, the seamless steel tube is ideal for mechanical engineering. To meet different demands, Luxing Pipe provides industrial pipe with different mass range, including carbon steel and alloy steel tubing. Our cleverly designed product comes with corrosion resistance, fine finish and long useful life.

Carbon steel pipe, alloy steel tube and other kinds of industrial tubes can be customized, so as to satisfy your requirements. According to market requirements, we will probably offer the steel gas fitting, stainless steel pipe and welding steel pipe in the future.

Parameters

1. Standard: EN 10297-1, 2

2. Steel grade: E235, E275, E315, E355, E470

3. Delivery condition: Normalizing or rolling

4. Outer diameter: 70MM-610MM

5. Wall thickness: 6MM-35MM

6. Tolerance: In line with EN 10297-1 standard

7. Length: Customization

8. Certificate: EN 10204/3.1

Delivery Condition of Seamless Steel Tube

| Steel grade | Delivery condition |

| E235 | Normalizing or rolling |

| E275 | Normalizing or rolling |

| E315 | Normalizing or rolling |

| E355 | Normalizing or rolling |

| E470 | Normalizing |

Chemical Composition (Heat Analysis)%

| Steel grade | C | Si | Mn | P | S | |||

| Min. | Max. | Min. | Max. | Min. | Max. | Max. | Max. | |

| E235 | - - | 0.17 | - - | 0.35 | - - | 1.20 | 0.030 | 0.035 |

| E275 | - - | 0.21 | - - | 0.35 | - - | 1.40 | 0.030 | 0.035 |

| E315 | - - | 0.21 | - - | 0.30 | - - | 1.50 | 0.030 | 0.035 |

| E355 | - - | 0.22 | - - | 0.55 | - - | 1.60 | 0.030 | 0.035 |

| E470 | 0.16 | 0.22 | 0.10 | 0.50 | 1.30 | 1.70 | 0.030 | 0.035 |

Mechanical Property

| Steel grade | Min. yield strength | Min. tensile strength | Min. elongation (%) | ||

| Mpa | Mpa | ||||

| T(mm) | T(mm) | I | |||

| ≤16 | >16 | ≤16 | >16 | ||

| ≤40 | ≤40 | ||||

| E235 | 235 | 225 | 360 | 360 | 25 |

| E275 | 275 | 265 | 410 | 410 | 22 |

| E315 | 315 | 305 | 450 | 450 | 21 |

| E355 | 355 | 345 | 490 | 490 | 20 |

| E470 | 470 | 430 | 650 | 600 | 17 |

| Notes: 1. “T” stands for wall thickness. 2. “I” stands for longitudinal. | |||||

Specification of Seamless Steel Tube

| Wall thickness | 6.3 | 7.1 | 8 | 8.8 | 10 | 11 | 12.5 | 14.2 | 16 | 17.5 | 20 | 22.2 | 25 | 28 | 30 | 35 | MM | ||

| Outer diameter | |||||||||||||||||||

| 70 | X | X | X | X | X | X | X | X | 70.0 | ||||||||||

| 73 | X | X | X | X | X | X | X | X | 73.0 | ||||||||||

| 76.1 | X | X | X | X | X | X | X | X | 76.1 | ||||||||||

| 82.5 | X | X | X | X | X | X | X | X | 82.5 | ||||||||||

| 88.9 | X | X | X | X | X | X | X | X | X | 88.9 | |||||||||

| 95 | X | X | X | X | X | X | X | X | X | 95.0 | |||||||||

| 101.6 | X | X | X | X | X | X | X | X | X | 101.6 | |||||||||

| 108 | X | X | X | X | X | X | X | X | X | 108.0 | |||||||||

| 114.3 | X | X | X | X | X | X | X | X | X | 114.3 | |||||||||

| 121 | X | X | X | X | X | X | X | X | X | 121.0 | |||||||||

| 127 | X | X | X | X | X | X | X | X | X | X | 127.0 | ||||||||

| 139.7 | X | X | X | X | X | X | X | X | X | X | 139.7 | ||||||||

| 146 | X | X | X | X | X | X | X | X | X | X | 146.0 | ||||||||

| 152.4 | X | X | X | X | X | X | X | X | X | X | 152.4 | ||||||||

| 159 | X | X | X | X | X | X | X | X | X | X | X | 159.0 | |||||||

| 168.3 | X | X | X | X | X | X | X | X | X | X | X | 168.3 | |||||||

| 177.8 | X | X | X | X | X | X | X | X | X | X | X | X | 177.8 | ||||||

| 193.7 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 193.7 | ||||

| 203 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 203.0 | ||||

| 219.1 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 219.1 | ||||

| 229 | X | X | X | X | X | X | X | X | X | X | X | 229.0 | |||||||

| 244.5 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 244.5 | ||||

| 254 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 254.0 | ||||

| 267 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 267.0 | ||||

| 273 | X | X | X | X | X | X | X | X | X | X | X | X | X | X | 273.0 | ||||

| 298.5 | X | X | X | X | X | X | X | X | X | X | X | X | 298.5 | ||||||

| 305 | X | X | X | X | X | X | X | X | X | X | X | X | 305.0 | ||||||

| 323.9 | X | X | X | X | X | X | X | X | X | X | X | X | 323.9 | ||||||

| 355.6 | X | X | X | X | X | X | X | X | X | X | X | X | X | 355.6 | |||||

| 368 | X | X | X | X | X | X | X | X | X | X | X | X | X | 368.0 | |||||

| 381 | X | X | X | X | X | X | X | X | X | X | X | X | X | 381.0 | |||||

| 394 | X | X | X | X | X | X | X | X | X | X | X | X | X | 394.0 | |||||

| 406.4 | X | X | X | X | X | X | X | X | X | X | X | X | X | 406.4 | |||||

| 419 | X | X | X | X | X | X | X | X | X | X | X | X | X | 419.0 | |||||

| 445 | X | X | X | X | X | X | X | X | X | X | X | X | X | 445.0 | |||||

| 457.2 | X | X | X | X | X | X | X | X | X | X | X | X | X | 457.0 | |||||

| 470 | X | X | X | X | X | X | X | X | X | X | X | X | X | 470.0 | |||||

| 508 | X | X | X | X | X | X | X | X | X | X | X | 508.0 | |||||||

| 521 | X | X | X | X | X | X | X | X | X | X | X | 521.0 | |||||||

| 530 | X | X | X | X | X | X | X | X | X | X | X | 530.0 | |||||||

| 559 | X | X | X | X | X | X | X | X | X | X | X | 559.0 | |||||||

| 610 | X | X | X | X | X | X | X | X | X | 610.0 | |||||||||

| Outer diameter | 6.3 | 7.1 | 8 | 8.8 | 10 | 11 | 12.5 | 14.2 | 16 | 17.5 | 20 | 22.2 | 25 | 28 | 30 | 35 | MM | ||

| Wall thickness | |||||||||||||||||||

Links:https://globefindpro.com/products/78941.html

-

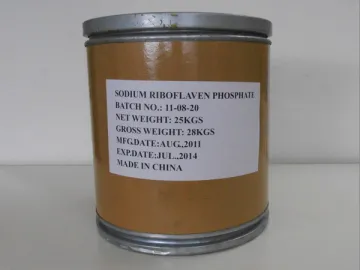

Riboflavin-5-Phosphate Sodium

Riboflavin-5-Phosphate Sodium

-

Astragalus Extract

Astragalus Extract

-

API 5L PSL1&PSL2 Steel Pipe

API 5L PSL1&PSL2 Steel Pipe

-

EN 10255 Steel Tube for Welding and Threading

EN 10255 Steel Tube for Welding and Threading

-

Sand Stone Glazed Porcelain Tiles

Sand Stone Glazed Porcelain Tiles

-

Maya Glazed Porcelain Tiles

Maya Glazed Porcelain Tiles

-

Hydrocortisone

Hydrocortisone

-

EN 10210 Hot Rolled Steel Structural Pipe

EN 10210 Hot Rolled Steel Structural Pipe

-

ASTM A519 Seamless Steel Pipe for Mechanical Engineering

ASTM A519 Seamless Steel Pipe for Mechanical Engineering

-

Hydrocortisone Acetate

Hydrocortisone Acetate

-

ASME SA53/ASTM A53 Seamless Steel Pipe

ASME SA53/ASTM A53 Seamless Steel Pipe

-

API 5L Corrosion Resistant Steel Pipe

API 5L Corrosion Resistant Steel Pipe