SSAW Steel Pipe

SSAW steel pipe is made of band steel or rolled steel plate with the processing of extrusion forming and double-seam double-sided submerged-arc welding. There is a submerged-arc welding seam on the inside and outside of the tube respectively. Our SSAW steel tube whose outside diameter ranges from 219.1mm to 2220mm and wall thickness ranges from 6mm to12mm complies with the standard of API 5L.

Application

Our product can be used to supply or drain water, transport coal gas, steam, and liquefied petroleum gas. It is also suitable for building structures in pile, bridge, wharf road, etc. As one of the 20 key products developed in China, our SSAW steel pipes are widely applied in public water supply engineering, petrochemical industry, chemical industry, electric power industry, agricultural irrigation and urban construction.

Our company is equipped with advanced production and testing equipment such as X-ray real time imaging system, magnetic defect detector, online or portable digital ultrasonic flaw detector, electric welding machine, wall thickness measure instrument, mechanical beveling machine, hydrostatic testing machine and hydrostatic test recorder. In addition, we also have independent physicochemical testing laboratory and welding laboratory. In the laboratories there are equipment testing the tensile strength, impact endurance, metallographic phase, hardness, chemical composition of our SSAW steel pipes.

By virtue of the advanced equipment and a group of professional managerial and technical staff, we can guarantee the spiral steel tubes we offer to customers have reliable quality.

Manufacturing Process

Parameters of SSAW Steel Pipe

Outside Diameter: 219.1mm-2220mm

Wall Thickness: 6mm-12mm

Material: Q235A, Q235B, 10#, 20#, Q345 (16Mn), L245 (B), L290 (X42), L320 (X46), L360 (X52), L390 (X56), L415 (X60), L450 (X65), L485 (X70), L555 (X80), L290NB/MB (X42N/M ), L360NB/MB (X52N/M), L390NB/MB (X56N/M), L415NB/MB (X60N/M), L450MB (X65), L485MB (X70), L555MB(X80)

Links:https://globefindpro.com/products/79135.html

-

Double-Row Tapered Roller Bearings

Double-Row Tapered Roller Bearings

-

Diva Engraving Machine

Diva Engraving Machine

-

CNC Electro-hydraulic Press Brake

CNC Electro-hydraulic Press Brake

-

Camaro Engraving Machine

Camaro Engraving Machine

-

Four Column Press

Four Column Press

-

4 Axis CNC Cutting Machine

4 Axis CNC Cutting Machine

-

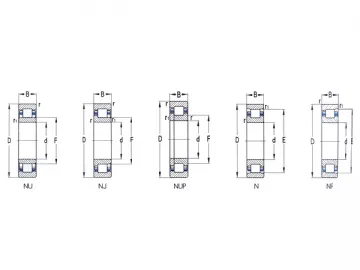

Single-Row Cylindrical Roller Bearings

Single-Row Cylindrical Roller Bearings

-

CA Series Spherical Roller Bearings

CA Series Spherical Roller Bearings

-

Double-Row Cylindrical Roller Bearings

Double-Row Cylindrical Roller Bearings

-

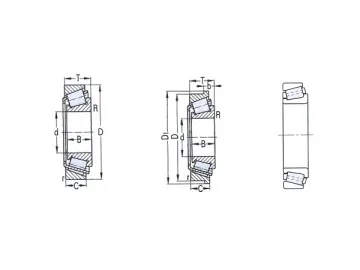

Single-Row Tapered Roller Bearings

Single-Row Tapered Roller Bearings

-

Thrust Ball Bearings

Thrust Ball Bearings

-

Single-Row Angular Contact Ball Bearings

Single-Row Angular Contact Ball Bearings