Introduction

Based on the 3-roller symmetrical structure, the hydraulic three roll machine is able to process plate as thick as 120mm and as wide as 3000mm. An upper roller vertically moves up and down in the central symmetrical position of two lower rollers. To realize hydraulic transmission, the hydraulic oil within the hydraulic cylinder exerts a force on the piston. The two lower rollers make a rotational motion, so as to let the output gear of reduction box mesh with the gear of lower roller, which provides torque for rolling plates. This hydraulic three-roll machine is commonly seen in shipbuilding, metal processing, iron and steel, windows and doors, home appliance and other industries.

Main Features of Hydraulic Three-Roll Machine

1. Its main parts are made of high-quality steel plates. The 3 rollers have followed multiple manufacturing procedures, ensuring good mechanical property.

2. The hydraulic three-roll machine is controlled by an electrical system. With easy operation, the console is placed away from the machine, which effectively guarantees operators’ security.

3. The machine tool is proud of high machining precision.

4. This plate bending roll owns 15 models to meet various needs.

Technical Parameters

| Model | W11-30×2000 |

| Maximum plate thickness | 30 |

| Maximum plate width | 2000 |

| Yield Strength of plate | 245 |

| Rolling speed | 4 |

| Minimum rolling diameter | 1200 |

| Upper roller diameter | 360 |

| Lower roller diameter | 290 |

| Distance between centers of two lower rollers | 480 |

| Main motor power | 22 |

| Hydraulic motor power | 7.5 |

| Model | W11-25×2500 |

| Maximum plate thickness | 25 |

| Maximum plate width | 2500 |

| Yield Strength of plate | 245 |

| Rolling speed | 4 |

| Minimum rolling diameter | 1200 |

| Upper roller diameter | 370 |

| Lower roller diameter | 300 |

| Distance between centers of two lower rollers | 480 |

| Main motor power | 22 |

| Hydraulic motor power | 7.5 |

| Model | W11-30×2500 |

| Maximum plate thickness | 30 |

| Maximum plate width | 2500 |

| Yield Strength of plate | 245 |

| Rolling speed | 4 |

| Minimum rolling diameter | 1200 |

| Upper roller diameter | 420 |

| Lower roller diameter | 360 |

| Distance between centers of two lower rollers | 550 |

| Main motor power | 30 |

| Hydraulic motor power | 11 |

| Model | W11-30×3000 |

| Maximum plate thickness | 25 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 4 |

| Minimum rolling diameter | 1200 |

| Upper roller diameter | 430 |

| Lower roller diameter | 370 |

| Distance between centers of two lower rollers | 550 |

| Main motor power | 30 |

| Hydraulic motor power | 11 |

| Model | W11-25×3000 |

| Maximum plate thickness | 30 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 4 |

| Minimum rolling diameter | 1200 |

| Upper roller diameter | 450 |

| Lower roller diameter | 390 |

| Distance between centers of two lower rollers | 600 |

| Main motor power | 37 |

| Hydraulic motor power | 11 |

| Model | W11-40×2500 |

| Maximum plate thickness | 40 |

| Maximum plate width | 2500 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 1400 |

| Upper roller diameter | 500 |

| Lower roller diameter | 400 |

| Distance between centers of two lower rollers | 600 |

| Main motor power | 37 |

| Hydraulic motor power | 15 |

| Model | W11-40×3000 |

| Maximum plate thickness | 40 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 1600 |

| Upper roller diameter | 540 |

| Lower roller diameter | 440 |

| Distance between centers of two lower rollers | 600 |

| Main motor power | 45 |

| Hydraulic motor power | 18.5 |

| Model | W11-50×3000 |

| Maximum plate thickness | 50 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 2000 |

| Upper roller diameter | 580 |

| Lower roller diameter | 480 |

| Distance between centers of two lower rollers | 750 |

| Main motor power | 55 |

| Hydraulic motor power | 22 |

| Model | W11-60×3000 |

| Maximum plate thickness | 60 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 2400 |

| Upper roller diameter | 660 |

| Lower roller diameter | 560 |

| Distance between centers of two lower rollers | 800 |

| Main motor power | 75 |

| Hydraulic motor power | 30 |

| Model | W11-70×3000 |

| Maximum plate thickness | 70 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 2800 |

| Upper roller diameter | 710 |

| Lower roller diameter | 620 |

| Distance between centers of two lower rollers | 850 |

| Main motor power | 90 |

| Hydraulic motor power | 37 |

| Model | W11-80×3000 |

| Maximum plate thickness | 80 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 3200 |

| Upper roller diameter | 770 |

| Lower roller diameter | 680 |

| Distance between centers of two lower rollers | 900 |

| Main motor power | 90 |

| Hydraulic motor power | 37 |

| Model | W11-90×3000 |

| Maximum plate thickness | 90 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 3600 |

| Upper roller diameter | 820 |

| Lower roller diameter | 730 |

| Distance between centers of two lower rollers | 950 |

| Main motor power | 110 |

| Hydraulic motor power | 45 |

| Model | W11-100×3000 |

| Maximum plate thickness | 100 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 4000 |

| Upper roller diameter | 860 |

| Lower roller diameter | 770 |

| Distance between centers of two lower rollers | 1000 |

| Main motor power | 110 |

| Hydraulic motor power | 45 |

| Model | W11-110×3000 |

| Maximum plate thickness | 110 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 4400 |

| Upper roller diameter | 900 |

| Lower roller diameter | 810 |

| Distance between centers of two lower rollers | 1080 |

| Main motor power | 132 |

| Hydraulic motor power | 55 |

| Model | W11-120×3000 |

| Maximum plate thickness | 120 |

| Maximum plate width | 3000 |

| Yield Strength of plate | 245 |

| Rolling speed | 3.5 |

| Minimum rolling diameter | 4800 |

| Upper roller diameter | 950 |

| Lower roller diameter | 860 |

| Distance between centers of two lower rollers | 1160 |

| Main motor power | 132 |

| Hydraulic motor power | 55 |

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#1d4ca6;','color:#fff;background:#4a4a4a','setclass')}

Zirkonzahn CAD/CAM System Compatible Zirconia Block

Zirkonzahn CAD/CAM System Compatible Zirconia Block

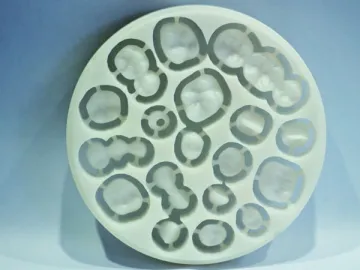

Open CAD/CAM System Compatible Zirconia Disc

Open CAD/CAM System Compatible Zirconia Disc

CNC Control Panel for Metal Shear

CNC Control Panel for Metal Shear

Swing Beam Shear

Swing Beam Shear

Amann Girrbach Manual System Compatible Zirconia Block

Amann Girrbach Manual System Compatible Zirconia Block

CM-Smart Manual 5 Dental Milling Machine

CM-Smart Manual 5 Dental Milling Machine

High Translucency Coloring Liquid for Zirconia Block

High Translucency Coloring Liquid for Zirconia Block

Amann Girrbach CAD/CAM System Compatible Zirconia Block

Amann Girrbach CAD/CAM System Compatible Zirconia Block

Shutze System Compatible Zirconia Block

Shutze System Compatible Zirconia Block

Super Translucency Coloring liquid for Zirconia Block

Super Translucency Coloring liquid for Zirconia Block

Cercon System Compatible Zirconia Block

Cercon System Compatible Zirconia Block

Roller Leveler

Roller Leveler