Swing Beam Shear

Our hydraulic swing beam shear adopts a well-known foreign brand of electrical system. All welded steel construction provides stable performance and good ruggedness. In blue-white or yellow-white, this sheet metal processing machinery looks simple and attractive. It can process sheet metal as thick as 4mm-25mm, and its maximum shearing width reaches up to 6000mm. The shearing machine is especially suitable for processing metallic materials in automobile, lamp pole, ship and other industries.

Features

1. Its ammonia gas cylinder helps to improves stability.

2. The gap adjustment of cutting edges is shown on an indicator. The operator can adjust the gap easily and rapidly.

3. The swing beam shear is provided with a lighting device, and supports infinitely adjusting the stroke of top tool rest.

4. There is a safety fence for protection.

5. A digital display device shows the back gauge size and shearing times.

6. We offer several CNC control panels for you to choose from.

Structure of Swing Beam Shear

1. Frame

The frame of swing beam shear features a rigid structure, providing high durability and good ruggedness. There are two cylinders fixed to the left and right columns. A movable tool rest is placed on the workbench, allowing fine tuning of the lower blade. In addition, ball transfer table is used for convenient material feeding.

2. Top Tool Rest

The tool rest features a welded steel structure. Its downward and upward stroke is powered by the return cylinder as well as said cylinders on the left and right column. It takes the eccentric locking collar as a pivot and swings back and forth, so as to shear materials. Its vertical blade bearing surface has been processed into an arc curve, guaranteeing consistency of the gap between the upper and lower blade.

3. Hold-down

The hold-down is a clamp for holding a sheet metal being sheared, preventing distortion and movement. The hold-down pressure is generated by cylinders on the bearing plate of swing beam shear. Once oil flows into the pressure cylinder, the hold-down feet will overcome the tension from a tension spring to press materials. With the aid of the spring, the device can returns to its original position at the end of shearing. The pressure grows with increasing thickness of materials.

4. Front and Back Gauge

1) Placed on the workbench, the front gauge shows numerical values by means of a scale. The desired gauge distance can be achieved through the adjustment of a stop dog. A long gauge is ideal for machining sheet steel.

2) The back gauge of swing beam shear is mounted on the top tool rest. It swings up and down along with the tool rest. The operator can make an adjustment through a motor. After a gear slows down, the gauge is driven by lead screws and may be adjusted via “ ” or “-” button. Additionally, the operator is able to rotate the regulating wheel for fine adjustment of the back gauge.

| Model | Thickness of processable sheet (mm) | Width of processable sheet (mm) | Rake Angle (° ) | Frequency of stroke (times/min) | Back gauge range (mm) | Main motor power (kw) |

| QC12Y-4×2000 | 4 | 2000 | 1° 30 ' | 20 | 20 ~600 | 4 |

| QC12Y-4×2500 | 4 | 2500 | 1° 30 ' | 20 | 20 ~600 | 4 |

| QC12Y-4×3200 | 4 | 3200 | 1° 30 ' | 18 | 20 ~600 | 5.5 |

| QC12Y-4×4000 | 4 | 4000 | 1° 30 ' | 16 | 20 ~600 | 5.5 |

| QC12Y-4×5000 | 4 | 5000 | 1° 30 ' | 14 | 20 ~600 | 7.5 |

| QC12Y-6×2000 | 6 | 2000 | 1° 30 ' | 20 | 20 ~600 | 7.5 |

| QC12Y-6×2500 | 6 | 2500 | 1° 30 ' | 18 | 20 ~600 | 7.5 |

| QC12Y-6×3200 | 6 | 3200 | 1° 30 ' | 14 | 20 ~600 | 7.5 |

| QC12Y-6×4000 | 6 | 4000 | 1° 30 ' | 14 | 20 ~600 | 7.5 |

| QC12Y-6×5000 | 6 | 5000 | 1° 30 ' | 8 | 20 ~600 | 11 |

| QC12Y-6×6000 | 6 | 6000 | 1° 30 ' | 10 | 20 ~600 | 11 |

| QC12Y-8×2500 | 8 | 2500 | 1° 30 ' | 12 | 20 ~600 | 11 |

| QC12Y-8×3200 | 8 | 3200 | 1° 30 ' | 10 | 20 ~600 | 11 |

| QC12Y-8×4000 | 8 | 4000 | 1° 30 ' | 8 | 20 ~600 | 11 |

| QC12Y-8×6000 | 8 | 6000 | 1° 30 ' | 10 | 20 ~600 | 22 |

| QC12Y-10×2500 | 10 | 2500 | 1° 30 ' | 10 | 20 ~600 | 15 |

| QC12Y-10×3200 | 10 | 3200 | 1° 30 ' | 10 | 20 ~600 | 15 |

| QC12Y-12×2500 | 12 | 2500 | 1° 30 ' | 8 | 20 ~800 | 18.5 |

| QC12Y-12×3200 | 12 | 3200 | 1° 30 ' | 10 | 20 ~800 | 18.5 |

| QC12Y-12×4000 | 12 | 4000 | 1° 30 ' | 10 | 20 ~800 | 18.5 |

| QC12Y-12×5000 | 12 | 5000 | 1° 30 ' | 8 | 20 ~800 | 22 |

| QC12Y-16×2500 | 16 | 2500 | 2° | 8 | 20 ~800 | 22 |

| QC12Y-16×3200 | 16 | 3200 | 2° | 8 | 20 ~800 | 22 |

| QC12Y-16×4000 | 16 | 4000 | 2° | 6 | 20 ~800 | 22 |

| QC12Y-20×2500 | 20 | 2500 | 2° 30 ' | 5 | 20 ~800 | 30 |

| QC12Y-20×3200 | 20 | 3200 | 2° 30 ' | 5 | 20 ~800 | 37 |

| QC12Y-25×2500 | 25 | 2500 | 3 °12' | 5 | 20 ~800 | 45 |

| QC12Y-25×3200 | 25 | 3200 | 3 ° | 5 | 20 ~800 | 45 |

Links:https://globefindpro.com/products/79179.html

-

Amann Girrbach Manual System Compatible Zirconia Block

Amann Girrbach Manual System Compatible Zirconia Block

-

CM-Smart Manual 5 Dental Milling Machine

CM-Smart Manual 5 Dental Milling Machine

-

CM-Smart 4 Dental Milling Machine

CM-Smart 4 Dental Milling Machine

-

Dental Alloy

Dental Alloy

-

Guillotine Shear

Guillotine Shear

-

Universal Rolling Machine

Universal Rolling Machine

-

CNC Control Panel for Metal Shear

CNC Control Panel for Metal Shear

-

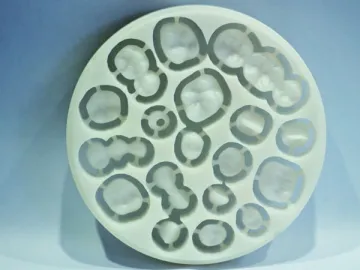

Open CAD/CAM System Compatible Zirconia Disc

Open CAD/CAM System Compatible Zirconia Disc

-

Zirkonzahn CAD/CAM System Compatible Zirconia Block

Zirkonzahn CAD/CAM System Compatible Zirconia Block

-

Hydraulic Three-Roll Machine

Hydraulic Three-Roll Machine

-

High Translucency Coloring Liquid for Zirconia Block

High Translucency Coloring Liquid for Zirconia Block

-

Amann Girrbach CAD/CAM System Compatible Zirconia Block

Amann Girrbach CAD/CAM System Compatible Zirconia Block