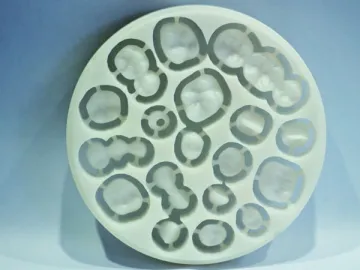

Dental Alloy

The dental alloy is a kind of high biological safety dental casting alloy. Built to meet ISO6871 standard, it features perfect ductility and toughness, superb casting property and ultra high corrosion resistance.

Percentage of Weight of Compositions

| Co | 63.0% |

| Cr | 30.0% |

| Mo | 5.0% |

| Mn | < 1.0% |

| Si | < 1.0% |

Physical Properties

| Density | 8.3g/cm3 |

| Solidus/Liquidus Melting Temperature | 1380℃ ~ 1400℃ |

| Hardness After Casting | 350HV10 |

| Elongation After Casting | ≥4% |

| Yield Strength After Casting | 630Mpa |

| Elastic Modulus | 210Gpa |

Co-Cr-Mo Dental Porcelain Alloy

This kind of dental alloy is high biological safety casting alloy without the harmful element Ni. It is made in compliance with ISO9693-1994 and YY0621-2008 standards. Remarkable features include high corrosion resistance, outstanding casting performance, as well as perfect ductility and toughness.

Percentage of Weight of Compositions

| Co | 60.0% |

| Cr | 24.0% |

| W | 9.0% |

| Mo | 5.0% |

Physical Properties

| Density | 8.0g/cm3 |

| Solidus/Liquidus Melting Temperature | 1210℃ ~ 1250℃ |

| Hardness After Casting | 320HV10 |

| Elongation After Casting | >8% |

| Yield Strength After Casting | 630Mpa |

| Elastic Modulus | 510Gpa |

| Coefficient of Thermal Expansion | (20℃ ~ 500℃): 13.9 × 10-6 K -1 (20℃ ~ 600℃): 14.3×10-6 K -1 |

Ni-Cr-Mo Dental Porcelain Alloy

As high bio-safe dental casting alloy, Ni-Cr-Mo dental porcelain alloy meets ISO9693-1994 and YY0621-2008 standards. It is characterized by high ductility and toughness, excellent casting property, and ultra strong corrosion resistance.

Percentage of Weight of Compositions

| Co | 56 .0% |

| Cr | 26 .0% |

| Mo | 10 .0% |

| Si | 1.8% |

Physical Properties

| Density | 8.2g/cm3 |

| Solidus/Liquidus Melting Temperature | 1340℃ ~ 1385℃ |

| Hardness After Casting | 210HV10 |

| Elongation After Casting | 12% |

| Yield Strength After Casting | 525Mpa |

| Coefficient of Thermal Expansion | (20℃ ~ 500℃): 13.8 ×10-6 K -1 (20℃ ~ 600℃): 14.0×10-6 K -1 |

Links:https://globefindpro.com/products/79183.html

-

Guillotine Shear

Guillotine Shear

-

Universal Rolling Machine

Universal Rolling Machine

-

Zirkon Zahn Manual System Compatible Zirconia Block

Zirkon Zahn Manual System Compatible Zirconia Block

-

Wieland System Compatible Zirconia Block

Wieland System Compatible Zirconia Block

-

CAD/CAM System Compatible Zirconia Disc

CAD/CAM System Compatible Zirconia Disc

-

Single-Action Drawing Press

Single-Action Drawing Press

-

CM-Smart 4 Dental Milling Machine

CM-Smart 4 Dental Milling Machine

-

CM-Smart Manual 5 Dental Milling Machine

CM-Smart Manual 5 Dental Milling Machine

-

Amann Girrbach Manual System Compatible Zirconia Block

Amann Girrbach Manual System Compatible Zirconia Block

-

Swing Beam Shear

Swing Beam Shear

-

CNC Control Panel for Metal Shear

CNC Control Panel for Metal Shear

-

Open CAD/CAM System Compatible Zirconia Disc

Open CAD/CAM System Compatible Zirconia Disc