Zirconia Sintering Furnace

Chang Mo can provide a full set of processing equipment from nanometer powder feeding to sinter molding. As a dental expert, we are delighted to share our knowledge and experience with customers.

The zirconia sintering furnace is used for preheating and sintering the zirconia dentures. It is a unique round furnace which adopts high-purity ceramic fiber materials to prevent zirconia from being polluted in the sintering process.

Automatic program control design allows the vacuum sintering furnace to control the whole working process. Various types of curing process and programmable process are provided to meet the needs of different zirconia materials and sintering processes. The use of high-temperature lock design system can avoid the deformation of a product caused by unexpected temperature drop in the zirconia sintering furnace.

Superiority

1. Selectable program timing and auto running functions allow the zirconia sintering furnace to save much power.

2. 15 fixed programs are provided for option. Additional 5 programs can be edited by users.

3. Superior-quality muffle allows the dental crown not to discolor.

4. High-definition LCD

5. Precise temperature control

6. High-quality heater element

7. Long lifespan of heating element

8. The chamber of our high temperature sintering furnace can accommodate two staggers simultaneously, thus featuring high efficiency.

9. The adoption of superior fire-resistant material allows the muffle to reduce energy by over 30%.

10. For better protecting the heating element, please avoid opening chamber because of faulty operation.

Technical Parameters

| Max. Temperature | 1600℃ |

| Max. Power Consumption | 3000 Watts |

| Size of Sintering Chamber (Diameter x Height) | Ф116mm×130mm |

| Program | 01 ~ 20 |

| Heat Rate | 0 ~ 30℃/minute |

| Sintering Temperature Range | 0 ~ 1620℃ |

| Hold-Time for Sintering Temperature | 0 ~ 540minutes |

| Dimension | 580 mm× 430 mm × 850mm |

| Weight (N.W.) | 96kg |

Links:https://globefindpro.com/products/79196.html

-

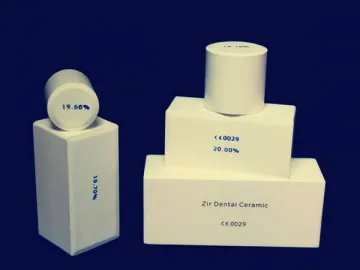

ST Pre-coloured Dental Zirconia Block

ST Pre-coloured Dental Zirconia Block

-

CM-Smart 5 Dental Milling Machine

CM-Smart 5 Dental Milling Machine

-

CNC Swing Beam Shear

CNC Swing Beam Shear

-

Mechanical Three-Roll Machine

Mechanical Three-Roll Machine

-

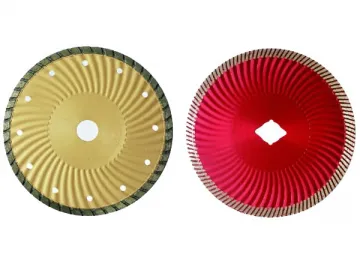

General Purpose Sintered Diamond Blade

General Purpose Sintered Diamond Blade

-

PTFE Adhesive Tape

PTFE Adhesive Tape

-

Hydraulic Rolling Shear

Hydraulic Rolling Shear

-

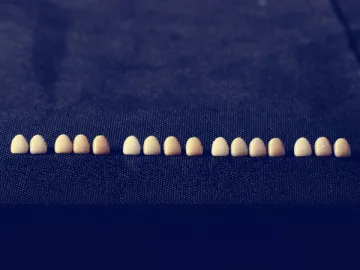

Dental Full Zirconia Crown

Dental Full Zirconia Crown

-

Sircona in Lab System Compatible Zirconia Block

Sircona in Lab System Compatible Zirconia Block

-

Kavo System Compatible Zirconia Block

Kavo System Compatible Zirconia Block

-

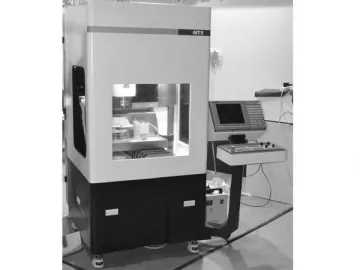

CM-MT5 Dental Milling Machine

CM-MT5 Dental Milling Machine

-

Single-Action Drawing Press

Single-Action Drawing Press