Mechanical Three-Roll Machine

The mechanical three roll machine makes use of the 3-roller symmetrical structure. Driven by lead screws, nuts, worms and turbines, the upper roller makes an up and down movement vertically in the symmetrical position of two lower rollers. The lower rollers rotate, making the reduction box gear mesh with the lower roller gear, so as to offer torque to roll plates. The thickness of processable plates should be less than or equal to 30mm, and the maximum width of plates is 3000mm.

Features of Mechanical Three-Roll Machine

1. Made of superior rolled steel, the plate rolling machine has received welding treatment. To ensure high ruggedness and good durability, its upper and lower rollers have gone through multiple manufacturing processes.

2. Controlled by an electrical system, this roll bending machine can be equipped with imported major components in accordance with your requirements.

3. Compared with the hydraulic one, this mechanical three-roll machine occupies smaller area. It comes with simple structure and easy maintenance.

4. There are over 20 models for you to choose from. Customization is available if required.

5. Our plate bending roll is extensively applied to manufacture cylindrical workpieces in petroleum, chemical, boiler, steel structure, machine-building and other industries.

Technical Parameters of Mechanical Three-Roll Machine

| Model | Maximum thickness | Maximum width | Yielding strength of plate | Rolling speed | Diameter of upper roller | Diameter of lower roller | Distance between centers of two lower rollers | Main power |

| W11-4X1500 | 4 | 1500 | 245 | 5 | 300 | 150 | 140 | 3 |

| W11-6X1500 | 6 | 1500 | 245 | 5 | 450 | 160 | 160 | 4 |

| W11-6X2000 | 6 | 2000 | 245 | 4.5 | 450 | 185 | 170 | 5.5 |

| W11-6X3200 | 6 | 3200 | 245 | 4.5 | 380 | 240 | 180 | 7.5 |

| W11-8X2000 | 8 | 2000 | 245 | 4.5 | 400 | 230 | 180 | 5.5 |

| W11-8X2500 | 8 | 2500 | 245 | 4.5 | 600 | 230 | 180 | 7.5 |

| W11-12X2000 | 12 | 2000 | 245 | 4.5 | 600 | 240 | 180 | 7.5 |

| W11-12X2500 | 12 | 2500 | 245 | 4.5 | 600 | 260 | 220 | 11 |

| W11-12X3000 | 12 | 3000 | 245 | 4 | 700 | 280 | 250 | 11 |

| W11-16X2000 | 16 | 2000 | 245 | 4 | 650 | 260 | 220 | 11 |

| W11-16X2500 | 16 | 2500 | 245 | 4 | 700 | 300 | 250 | 15 |

| W11-16X3200 | 16 | 3200 | 245 | 4 | 850 | 340 | 280 | 18.5 |

| W11-20X2000 | 20 | 2000 | 245 | 4 | 700 | 280 | 250 | 15 |

| W11-20X2500 | 20 | 2500 | 245 | 4 | 850 | 340 | 280 | 18.5 |

| W11-25X2000 | 25 | 2000 | 245 | 4 | 850 | 330 | 270 | 18.5 |

| W11-25X2500 | 25 | 2500 | 245 | 4 | 1200 | 380 | 310 | 22 |

| W11-30X2500 | 30 | 2500 | 245 | 4 | 1200 | 400 | 350 | 30 |

| W11-30X3000 | 30 | 3000 | 245 | 4 | 1200 | 450 | 390 | 37 |

Because of product improvement, the parameters are subject to change without notice in line with accompanying technical documents.

window.onload =function(){setItemByDivId('container','one|two|three|four|five|six|seven|eight','etw_link','color:#fff; background:#1d4ca6;','color:#fff;background:#4a4a4a','setclass')}

Links:https://globefindpro.com/products/79200.html

-

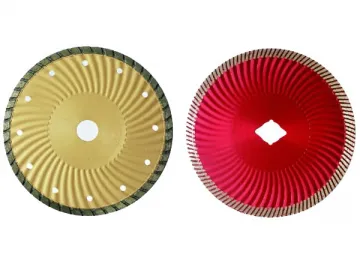

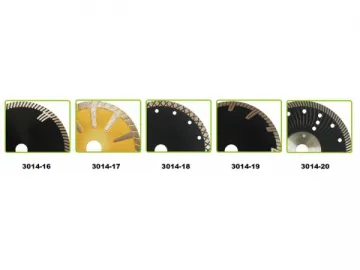

General Purpose Sintered Diamond Blade

General Purpose Sintered Diamond Blade

-

PTFE Adhesive Tape

PTFE Adhesive Tape

-

PTFE Coated Kevlar

PTFE Coated Kevlar

-

Sintered Diamond Blade for Stone

Sintered Diamond Blade for Stone

-

Brazed Diamond Wire Saw

Brazed Diamond Wire Saw

-

Diamond Blade for Ceramics

Diamond Blade for Ceramics

-

CNC Swing Beam Shear

CNC Swing Beam Shear

-

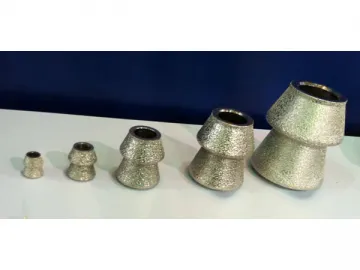

CM-Smart 5 Dental Milling Machine

CM-Smart 5 Dental Milling Machine

-

ST Pre-coloured Dental Zirconia Block

ST Pre-coloured Dental Zirconia Block

-

Zirconia Sintering Furnace

Zirconia Sintering Furnace

-

Hydraulic Rolling Shear

Hydraulic Rolling Shear

-

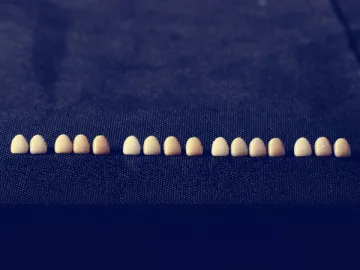

Dental Full Zirconia Crown

Dental Full Zirconia Crown