TBBPA /TBBA Flame Retardant

Brief Introduction

| CAS No. | 79-94-7 |

| Properties | The TBBPA flame retardant is white crystalline powder. |

| Solubility | This product is soluble in methanol, ethanol, acetone and toluene. It is also soluble in sodium hydroxide solution. It is slightly soluble in water. |

| Applications | 1. Our TBBA flame retardant is commonly used for reducing flammability of synthetic materials. 2. Due to low toxicity and strong compatibility with base materials, this product gives a wide range of applications. 3. As an additive, this fire retardant is mainly applied in ABS, HIPS, epoxy resins, phenolic resins, unsaturated polyesters, etc. 4. As a reactive flame retardant, TBBPA is often used for the production ofbrominated epoxy resin intermediates and brominated polycarbonates. 5. In addition, this product can be also applied in industries such as the coatings, adhesives, potting compounds, glass reinforced plastics, and the plastics modification. |

Advantages of TBBA for Engineering Plastics

Tetrabromobisphenol A, also known as TBBA or TBBPA, gives a wide range of applications in fire-retardant engineering plastics, especially in ABS. It can offer the following advantages.

1. TBBA does not produce any carcinogen during combustion. Also, it does not cause toxicity.

2. In comparison with other commonly used brominated flame retardants, TBBA mixed with ABS can offer better processability. It gives a higher melt flow rate (MFR) under the same processing conditions. Therefore, the manufactured goods are provided with better surface smoothness, thus being ideal for producing high-end products.

3. TBBA is well compatible with ABS, and thereby the surface of final products is non-blooming.

4. As an efficient fire retardant, TBBA can offer a high cost-performance ratio. It helps achieve the ULV0 standard.

Applications of TBBA in Brominated Epoxy Resins

TBBA is ideal for the preparation of liquid-state brominated epoxy resins, which are used extensively for reducing flammability of epoxy copper-clad laminate. The copper-clad laminate can act as a raw material of epoxy printed circuit boards (PCB).

TBBA can be also used to produce solid-state brominated epoxy resins. This kind of resin is a high-performance fire retardant for engineering plastics.

Packing

The TBBPA fire retardant is packed in a 25kg kraft bag. Customization service is also available.

Quality Standard

| Items | Index |

| Melting Point | ≥180 ℃ |

| Bromine Content | ≥58.5% |

| Loss on Drying | ≤0.10% |

| Free Bromine | ≤10ppm |

| Color | ≤20APHA |

| Whiteness | ≥59 |

Storage and Transportation

Our product must be handled with care. It should keep dry and air-tight during storage.

Links:https://globefindpro.com/products/79361.html

-

MH-4802 Flame Retardant Masterbatch for PP (V2 UL94)

MH-4802 Flame Retardant Masterbatch for PP (V2 UL94)

-

Waist Shape Pipe Brush

Waist Shape Pipe Brush

-

Long Handle Floor Brush

Long Handle Floor Brush

-

Floor Brush

Floor Brush

-

MH-7800 Flame Retardant Masterbatch for ABS

MH-7800 Flame Retardant Masterbatch for ABS

-

Eco-friendly Flame Retardant for PP

Eco-friendly Flame Retardant for PP

-

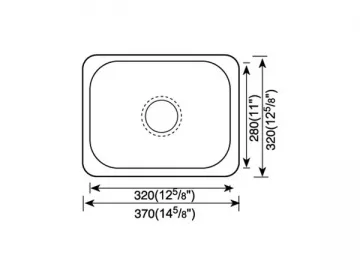

300MM-400MM Kitchen Sink

300MM-400MM Kitchen Sink

-

Flat Rim Single Bowl Sink

Flat Rim Single Bowl Sink

-

Small Size Topmount Sink

Small Size Topmount Sink

-

Drainer Basket

Drainer Basket

-

Soap Dispenser

Soap Dispenser

-

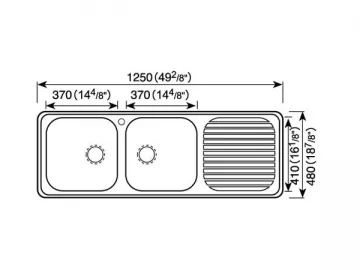

1200MM-1300MM Kitchen Sink

1200MM-1300MM Kitchen Sink