MH-7800 Flame Retardant Masterbatch for ABS

The MH-7800 flame retardant masterbatch for ABS is formed by an efficient compound flame retardant with our unique technology. It features dependable fire resistance, good dispersion, and strong compatibility with matrix resin. This product is ideal for use in ABS and HIPS resins. As an ABS additive, it is widely applied in coal mine, electrical appliances, automobile, railway, and other industries.

Feature

1. Our flame retardant masterbatch for ABS is marked by easy use, high safety, and no dust pollution. It fully conforms to environmental requirements of SGS.

2. This product adopts Graft copolymer of styrene and butadiene as a carrier. It has perfect compatibility and dispersion with ABS plastics. Additionally, it offers good impact toughness and processing mobility.

3. Due to high thermal stability, our product is suitable for use in occasions where a high processing temperature of above 300℃ is required.

4. Due to high melting point, the flame retardant masterbatch for ABS is non-stick when being dried with ABS.

Technical Index

| Items | Unit | MH-7801 | MH-7802 |

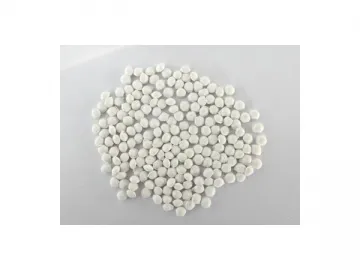

| Appearance | - | White Spherical Granules | White Spherical Granules |

| FR content | % | 80 min. | 80 min. |

| Moisture | ppm | 2000 max. | 2000 max. |

| Density | g/cm3 | 1.8±0.2 | 1.6±0.2 |

| Application | - | General ABS | Eco-friendly ABS |

| Recommended Dosage | % | 15-20 | 15-20 |

Packing and Storage

The flame retardant masterbatch for ABS is wrapped in a 25kg/bag paper-plastic compound outer and PE inner bag. This product is stored at room temperature. It must keep dry and air-tight to resist moisture.

Suggestion

1. In case of long-term storage, please dry our product before using.

2. Our customers had better know the process conditions and properties of products, and then choose the best process parameters for production before use.

3. The above-mentioned data is laboratory reference values. The last application depends on customer requirements.

Links:https://globefindpro.com/products/79368.html

-

Eco-friendly Flame Retardant for PP

Eco-friendly Flame Retardant for PP

-

Handmade Sink

Handmade Sink

-

MH-3800 Flame Retardant Masterbatch for XPS

MH-3800 Flame Retardant Masterbatch for XPS

-

FR245 Flame Retardant

FR245 Flame Retardant

-

MH-5800 Flame Retardant Masterbatch for PP

MH-5800 Flame Retardant Masterbatch for PP

-

MH-4801 Halogen-free Flame Retardant Masterbatch for PP

MH-4801 Halogen-free Flame Retardant Masterbatch for PP

-

Floor Brush

Floor Brush

-

Long Handle Floor Brush

Long Handle Floor Brush

-

Waist Shape Pipe Brush

Waist Shape Pipe Brush

-

MH-4802 Flame Retardant Masterbatch for PP (V2 UL94)

MH-4802 Flame Retardant Masterbatch for PP (V2 UL94)

-

TBBPA /TBBA Flame Retardant

TBBPA /TBBA Flame Retardant

-

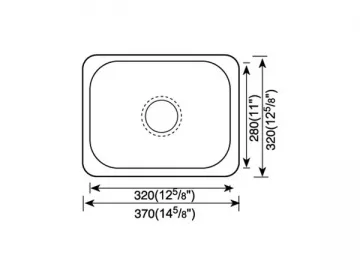

300MM-400MM Kitchen Sink

300MM-400MM Kitchen Sink