MH-4801 Halogen-free Flame Retardant Masterbatch for PP

The MH-4801 halogen-free flame retardant masterbatch for PP is an environmentally friendly flame retardant system containing phosphorus and nitrogen. Based on MH-FR/PP-1 product, development of non-precipitation intumescent halogen-free flame retardant masterbatch for PP can meet different application requirements of customers.

In comparison with FR powder, our halogen-free flame retardant masterbatch features convenient processing, easy dispersion, and strong compatibility with matrix resin. This fire retardant system is especially suitable for use in various PP materials or other polyolefin.

Proper addition of our product allows PP to reach flammability rating UL94-V0 (1.5mm). Additionally, the halogen-free flame retardant masterbatch has passed both RoHS certification and 850℃ hot glow-wire test. Other prominent characteristics include low smoke amount, ultra high cost-performance ratio, and low corrosion to moulds, etc.

Advantages

1. High Processing Temperature

Our product can offer processing temperature of above 270 degrees Celsius to meet the requirements of various polymers, especially polypropylene.

2. Good Compatibility

The intumescent halogen-free flame retardant masterbatch is well compatible with PP, PE, and EVA. Therefore, the end product is also provided with superb mechanical properties.

3. Strong Ageing Resistance

Our product can be recycled and re-processed. It fully satisfies environmental requirements.

Main Specifications

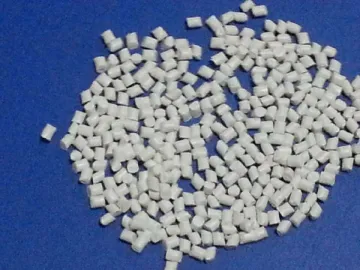

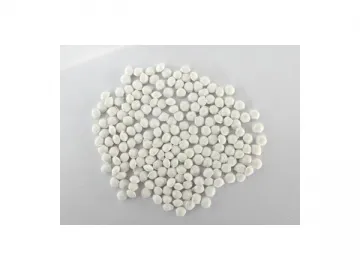

| Appearance | White Granules |

| FR Content | 80% min. |

| Density | 1.4±0.1 g/cm3 |

| Decomposition Temperature | 270 ℃ min. |

Recommended Dosage

| Resin Type | PP | PP | HDPE, EVA or HDPE/EVA Copolymer |

| MH-FR4801 | 30% | 35% | 35% min. |

| FR Grade | V0 (3.0mm) | V0 (1.5mm) | V0 (1.5mm) |

Note

1. Adjustable Extrusion Process

Firstly, the twin-screw processing temperature should not be too high, or else mild foaming will occur resulted from a small amount of flame retardant decomposition.

Secondly, a filter should not be added during extrusion process, otherwise foaming will occur easily.

Thirdly, please maintain a certain degree of vacuum in the extrusion process to make extruded materials stable.

2. Based on different requirements of final products, please choose a suitable resin to make both extrusion processing and injection molding processes much easier.

3. A formulation system can not be added with substances which may cause flame-retardancy failure. When the dosage of carbon black is higher than 0.5%, the halogen-free flame retardant masterbatch will cease to be effective. Additionally, the fire retardant may be affected by inorganic padding materials such as fiber glass, calcium carbonate, talc, barium sulfate, etc.

Packing, Storage and Transportation

Our product is packed in a complex paper bag lined with PE bag. Its net weight is 25kg/bag. This product must keep dry and air-tight. It is transported according to the requirements of general chemicals.

Links:https://globefindpro.com/products/79374.html

-

MH-3700 Flame Retardant Masterbatch for Fiber Spinning

MH-3700 Flame Retardant Masterbatch for Fiber Spinning

-

BPS Flame Retardant

BPS Flame Retardant

-

Long Handle Cleaning Brush

Long Handle Cleaning Brush

-

Round Dust Brush

Round Dust Brush

-

DBDPO/DECA Flame Retardant

DBDPO/DECA Flame Retardant

-

Triple Bowl Sink

Triple Bowl Sink

-

MH-5800 Flame Retardant Masterbatch for PP

MH-5800 Flame Retardant Masterbatch for PP

-

FR245 Flame Retardant

FR245 Flame Retardant

-

MH-3800 Flame Retardant Masterbatch for XPS

MH-3800 Flame Retardant Masterbatch for XPS

-

Handmade Sink

Handmade Sink

-

Eco-friendly Flame Retardant for PP

Eco-friendly Flame Retardant for PP

-

MH-7800 Flame Retardant Masterbatch for ABS

MH-7800 Flame Retardant Masterbatch for ABS