MH-3700 Flame Retardant Masterbatch for Fiber Spinning

The MH-3700 flame retardant masterbatch for fiber spinning contains a fire-retardant ingredient that can replace the previously-used brominated aliphatic hydrocarbon flame retardant. It does not contain antimonous oxide and other inorganic substances. This product features moderate melting point, ultra high thermal stability, and strong resistance to light-heat aging. It can greatly reduce flammability of PP, PE, and other polyolefin.

Our flame retardant masterbatch is particularly suitable for use in the polyolefin-based thin materials, fibers, wigs and non-woven fabrics, among others. It is also applicable for a variety of engineering plastics such as PBT, PC/ABS, PC/PET and PET, etc.

Characteristics

1. Superior Processability

The flame retardant masterbatch can be dosed and used conveniently. Striking advantages include good spinnability, anti-blocking performance, high safety, and no dust pollution.

2. High-Performance Fire Retardant

This fire-retardant material can guard against fire by means of char-forming mechanism in a condensed phase. It is closely related to the oxygen index of polymers and the amount of char during combustion.

3. Superb Light-Heat Stability and High Chemical Resistance

Physical and Chemical Properties Compared with TBC, HBCD Synthetic Flame Retardant Masterbatch

| Index | MH-3700 | TBC Sb2O3 | HBCD Sb2O3 |

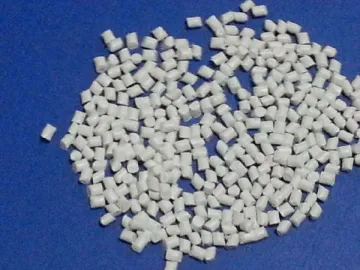

| Appearance | White Granule | White Granule | White Granule |

| Melting Point ℃ | 180-183 | 102-106 | 178-186 |

| Br Content % | 58 | 46 | 59 |

| P Content % | 2.2 | / | / |

| TGA/Temperature ℃ | |||

| 1%5%10% | 282310325 | 220265280 | 202260264 |

| Remark: TGA rate is test by Du Pont 2000 thermal analyzer. Test conditions: 1. Heating rate: 10℃/min 2. Atmosphere: nitrogen 3. Starting temperature: 100°C 4. Final temperature: 500℃ | |||

Properties of MH-3700 Flame Retardant Polyolefin

| Resin | MH-3700 Dosage | UL94 | Discoloration Resistance | Gloss Performance | Chemical Resistance |

| PP | 5.0 | V-2 | Good | Excellent | Good |

| HDPE | 5.0 | V-2 | Good | Excellent | Good |

| ABS | 5.0 | V-2 | Good | Excellent | Poor |

| HIPS | 5.0 | V-2 | Good | Excellent | General |

| Suggestion: A formulation can be added with a proper amount of antioxidant from 0.1% to 0.5%. | |||||

Packing and Transportation

The flame retardant masterbatch for fiber spinning is packed in a complex paper bag lined with PE bag. Its net weight is 25kg/bag. This product is transported according to the standard of general chemicals. It must be sealed and stored in a dry and cool room.

Links:https://globefindpro.com/products/79375.html

-

BPS Flame Retardant

BPS Flame Retardant

-

Long Handle Cleaning Brush

Long Handle Cleaning Brush

-

Round Dust Brush

Round Dust Brush

-

DBDPO/DECA Flame Retardant

DBDPO/DECA Flame Retardant

-

Triple Bowl Sink

Triple Bowl Sink

-

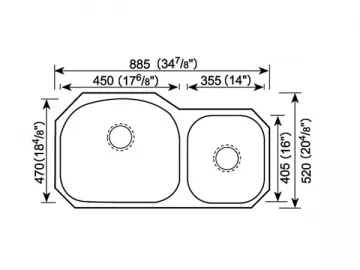

Undermount Double Bowl Sink

Undermount Double Bowl Sink

-

MH-4801 Halogen-free Flame Retardant Masterbatch for PP

MH-4801 Halogen-free Flame Retardant Masterbatch for PP

-

MH-5800 Flame Retardant Masterbatch for PP

MH-5800 Flame Retardant Masterbatch for PP

-

FR245 Flame Retardant

FR245 Flame Retardant

-

MH-3800 Flame Retardant Masterbatch for XPS

MH-3800 Flame Retardant Masterbatch for XPS

-

Handmade Sink

Handmade Sink

-

Eco-friendly Flame Retardant for PP

Eco-friendly Flame Retardant for PP