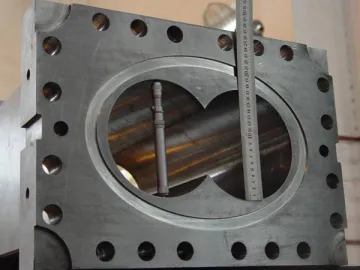

Barrel and Screw Material

Sintered alloy produced with HIP technique is a kind of high quality material, which features high density, segregation-free, micropore defect free. It stands out for its excellent anti-wear performance, making it a kind of desirable material for the twin screw extruder, especially for screw elements. Thus the severe contradiction between the hard screw surface and tenacious screw core is perfectly taken care of.

| Internal name | Material Type | Characteristic | Wear resistance | Corrosion resistance | Typical application & structure characteristic |

| 38CrMoAlA | Nitriding steel | Ordinary working conditions | * | ** | Screw elements and barrel |

| Cr12MoV | Tool steel | High abrasion conditions like fiberglass processing | ** | ** | Screw elements and integral barrel liners |

| W6Mo5Cr4V2 | Tool steel | High abrasion conditions like fiberglass processing | *** | * | Screw elements and integral barrel liners |

| α101 | Fe,Ni,B | High abrasion conditions like fiberglass processing | **** | ** | Centrifugal casting bimetallic split C liners |

| CB-HS10 | PW HIP | High vanadium content sintered alloy with evenly distributed high content super-hard carbide (HV2800). | ******* | ** | Screw core; Bimetallic material with high tenacity; Typical wear resistant material for high-end twin screw |

| CB-HS20 | PW HIP | High chromium content sintered alloy tool steel with evenly distributed high content super-hard carbide; Excellent wear resistance and corrosion resistance. | ***** | ***** | Screw core; Bimetallic material with high tenacity; |

| CB-HS26 | PW HIP | High chromium content sintered alloy tool steel with evenly distributed high content super-hard carbide; Excellent wear resistance, toughness and corrosion resistance. | ******* | ****** | Bimetallic integral liner |

| CB-HS11 | PW HIP | High chromium and cobalt content sintered alloy high speed steel with evenly distributed high content super-hard carbide; Excellent toughness at high temperature;High wear resistance | ******** | ** | Screw core; Bimetallic material with high tenacity |

Scan QR to Read

Links:https://globefindpro.com/products/79725.html

Links:https://globefindpro.com/products/79725.html

Recommended Products

Hot Products