Twin-Rotor Continuous Mixer

1. The twin-rotor continuous mixer can achieve continuous production property in addition to the traditional mixer’s great mixing performance and wider parameter setting range. Just like the co-rotating twin screw extruder,the CM series twin-rotor continuous mixer is a kind of advanced and high performance blending facility. The two kinds of machine have different but complementary applications in the mixing and modification of plastic and rub.

2. The CMcontinuous mixing equipment is based on the stretching mixing technique, thus the power consumption will be lower. Besides, in the manufacturing of many kinds of master batch or mixing materials with high content of carriers, and processing aids usage will be eliminated or greatly reduced. By the improvement mentioned above, the production techniques and the product cost are optimized.

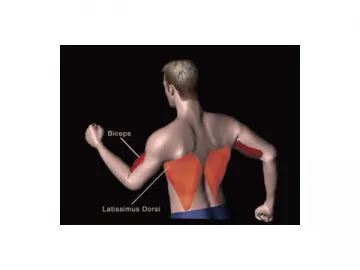

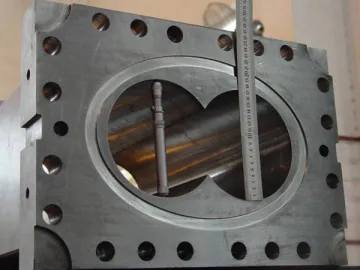

3. The main part of the machine comprise three systems, namely none-engaged screw twin crew material feeding system, dual-rotor mixing system and the twin screw extruding system. The two none-engaged counter-rotate mixing rotors, together with the extrusion pressure control devise, leads to optimized material residence time, degree of fill and the mixing performance.

4. Comparing to the twin screw extruder, our CM series two-rotor continuous blending machine has lager tube volume and are suitable for more material types (i.e. fluffy or big size material). The main part of the machine is designed as split-type so that it is simple to clean and maintain, and exchange the production material.

5. The two rotors in the mixing process have been lengthened to enhance the venting and mixing performance. The application range is also expanded.

6. The twin-rotor continuous mixer comes with different types of rotor. Combining with adjustable embedding type barrel, parameters and their combinations of the mixer will be more variable, and then a wider range of material could be handled and more processing techniques can be adopted.

7. The rotors of the mixer are supported at both ends, so they can bear more pressure. Friction and abrasion between the screw and the barrel are thus avoided.

Application

The CM series twin-rotor continuous mixer is typically suitable for high degree filling, mixing and modifying operation, such as the filling of various special materials, functional master batch, color master batch, black master batch, flame retardant master batch, shielding master batch, elastomer, and the mixture of rubber and plastic.

| Type | Continuous mixer single screw | CM-50/SE100 | CM-75/SE120 | CM-100/SE150 | CM-130/SE180 |

| Continuous mixer melt pump | CM-50/RB100 | CM-75/RB200 | CM-100/RB315 | CM-130/RB500 | |

| Dual-rotor mixer | Rotor nominal diameter (mm) | 50 | 75 | 100 | 130 |

| Rotor L/D | 10 | 10 | 10 | 10 | |

| Rotor max.speed (rpm) | 1000 | 800 | 600 | 500 | |

| Main motor power (kw) | 30 | 75/90 | 132/160 | 250/315 | |

| Single-screw extruder | Screw diameter (mm) | 100 | 120/150 | 150/180 | 180/200 |

| Screw L/D | 11 | 11 | 11 | 11 | |

| Screw Max.rotating speed (rpm) | 95 | 120 | 120 | 100 | |

| Motor power (kw) | 15 | 37/45 | 45/55 | 55/75 | |

| Melt pump | Conveying capacity (ml/r) | 100 | 200 | 315/400 | 500/800 |

| Motor power (kw) | 4 | 7.5 | 15 | 22 | |

| Typical output capacity (kg/h) | 60-150 | 150-450 | 300-800 | 650-1500 |

Links:https://globefindpro.com/products/79728.html