WB21,WB23 Front and Rear Axles for Concrete Mixer Truck

Description

WB21 and WB23 front and rear axle for concrete mixer truck are designed for the market. These products are suitable for concrete mixer trucks with 2.1 to 2.3m wide mixer and other engineering machinery at the same level.

Our front and rear axle for concrete mixer truck have passed the 500-hour strength test at the national level in China, so the quality is ensured. We mainly supply the products for XCMG, Degong,Yituo (Luoyang) Building Machinery, Dezhougonglu and WBEST, etc. Besides, customized design and manufacture of axles are provided to meet customers’ requirement.

Classification

1. Front Axles for Concrete Mixer Truck

The front axle adopts wholly welded method, so it has better load bearing capacity. Besides, it is the hydraulic steering axle adopting Steyr steering universal joints. The whole structure is reliable and compact, and the steering becomes easy and flexible. Therefore, our product is widely used for WB21 and WB23 mixer trucks as well as other similar machines. After minor change, it also can be applied to other engineering machinery such as crushers.

The picture below shows the basic geometry of steering. M indicates the distance between two kingpins, 1 means the steering arm and 2 is the tie rod. These three factors compose the steering trapezoid. This proper structure enables non-slipping run.

1. 1: Steering arm

2. 2: Tie rod

3. M: Distance between Two Kingpins

4. Rmin: Minimum turn radius

5. L: Distance between axles

6. B: Distance between wheels

α≠β and ctgα-ctgβ=M/L

If the equation is satisfied, then all wheels will be in non slip condition during turning.

2. Rear Axles for Concrete Mixer Truck

A. Complete with three-stage reduction design, the final reduction gear ratio is 163.24.

B. The hub reduction adopts the NGW planetary design, which ensures reliable performance.

C. The sizes of motors input ports come in variety of offering to meet clients’ needs.

D. The inner drum brake is applied for service brake and parking brake.

Technical specification

Front axle

| Nominal load rating of axle (t) | Max. vehicle speed | Turning angle | Max. oscillation angle | Steering mode | Toe in | |||

| 7.5t | 50km/h | ±37 ° | ±11.5 ° | Hydraulic power steering | 3.7mm | |||

| Connecting dimensions | Model Specification | L1 | L2 | L3 | L4 | D1 | D2 | D3 |

| WB23A | 950 | 592 | 110 | 669 | Φ30h6 | Φ40h6 | Φ 30 ▷ 1: 10 | |

| WB23B | 920 | 135 | ||||||

| WB23C | 1360 | 945 | 590 | Excluded in supply | Φ 24H8 (Straight hole) | |||

Rear axle

| Axle ratio | I | 23.26 | Load capacity of axle | 20000kg |

| Max. input torque | 712.5N.m | |||

| Gear ratio of gearbox | I1 | 1 | Gear shifting pressure | 0.6-0.8MPa |

| I2 | 7.02 | Stroke of gear shifting | 17.5± 1 |

| Motor connecting dimensions | Model | Number of teeth | Diametrical pitch (module) | CXC | D1 | H | D2 | D3 |

| Sauer | 23 | Dp =16/32 | 154× 154 | Φ 127H6 | 16 | M14 | Φ 162 | |

| Rexroth | 21 | |||||||

| Rexroth | 18 | M=2 | 185× 185 | Φ 160H7 | 40.5 | M16 | Φ 200 | |

| Rexroth | 21 |

Front axles and rear axles for mixing machine

Related Names

4 Wheel Drive Axle | Front Axle Assembly | Rear Differential Carrier

Links:https://globefindpro.com/products/80844.html

-

ZL15,ZL15-1 Series Torque Converter and Gearbox

ZL15,ZL15-1 Series Torque Converter and Gearbox

-

Shatter-Proof Glass

Shatter-Proof Glass

-

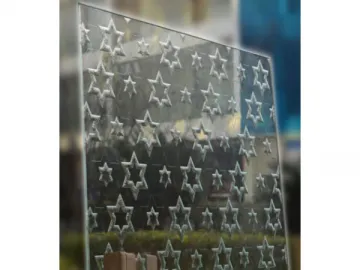

Printed Glass

Printed Glass

-

JC98 Steering Front and Rear Axle for Grader

JC98 Steering Front and Rear Axle for Grader

-

Laminated Glass

Laminated Glass

-

Curved Toughened Glass

Curved Toughened Glass

-

Q20 Drive Axle for Wheel Tractor

Q20 Drive Axle for Wheel Tractor

-

Fire Resistant Glass

Fire Resistant Glass

-

Membrane Horn Switch

Membrane Horn Switch

-

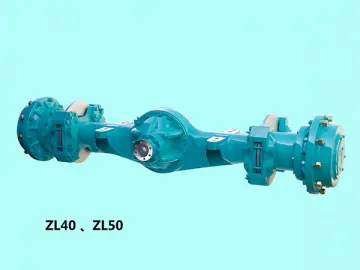

ZL40,ZL50 Series Drive Axles for Loader

ZL40,ZL50 Series Drive Axles for Loader

-

Processed Glass

Processed Glass

-

Blast Resistant Glass

Blast Resistant Glass