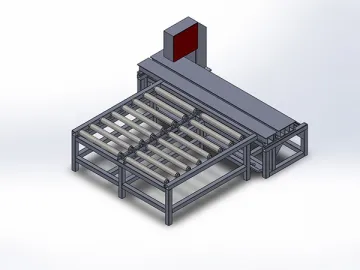

CNC Turret Punch Press

Features

1. The CNC turret punch press is used for plate punching and processing with high accuracy and efficiency. It comes with rational structure and remarkable performance.

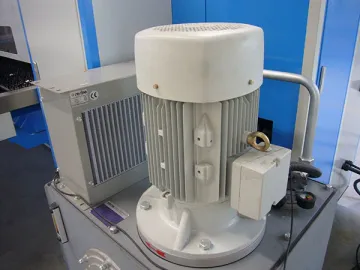

2. It adopts the internationally high-rank numerical control system, power system, guide screw and the guide rail to well guarantee the workpiece quality.

3. With dependable performance, it is configured with automatic die choosing system, high-speed servo feed system and complete die types. The dedicated punching function and the automatic programming software are optionally available. Meanwhile, it enables automatic detection, protection and self-diagnosis.

4. It is highlighted by the advantages as high flexibility, short die debug time, high automaticity and the capability of processing large-sized plates.

5. The main body of CNC turret punch press is wide and highly steady in closed type. The inlaid thick turret features accurate side positioning and excellent guiding.

6. The internationally advanced Fanuc CNC system from Japan with robust function is convenient in operation. The high-end hydraulic system is imported from H L of German with stable performance and low consumption. We also import the high-speed mute self-lubricating lead screw as well as the matched pneumatic and electric elements.

7. This machine is also provided with an automatic floating clamp and the operating platform with steel balls and brushes.

Applications

The CNC turret punch press suits single-time hole punching of various shapes, sizes and intervals, and nibbling of larger round holes, square holes, slotted holes and holes in other shapes. It is also capable of shutter processing, light stretching, embossing, flanging and spare hole processing. It especially fits the industries processing various plates in small volume, such as the electric switch, electronic instrument, computer, household appliance, light industry, etc.

Inviting Strengths

Compared with the common similar products, this machine possesses the following strengths:

1. Manpower saving: It enables to process the entire piece of plate and to automatically feed materials.

2. Computing time saving: Automatic transferring and processing of CAD diagram is realizable.

3. Positioning time saving: Pneumatic gripping and automatic positioning are available for the CNC turret punch press.

4. Die changing time saving: The high-speed die changing mechanism is adopted.

5. Production efficiency improvement: Compared with the common punching machine, it improves the production efficiency by 6 to 7 times.

6. High safety coefficient: The realization of unattended operation maximally avoids the potential hazards.

7. Advanced components: This product is a perfect combination of the modern control technology and the traditional machine. It plays a leading role in this industry in virtue of high automaticity, high precision and efficiency, stable performance and high safety and reliability. It is really an ideal choice for metal plate industry.

Technical Parameters

| Item | Unit | HT30A | HT30B | HT30C | HT30D | HT40B | HT50E |

| Nominal pressure | KN | 300 | 300 | 300 | 300 | 400 | 500 |

| Maximum workpiece thickness | mm | 6 | 6 | 6 | 6 | 6 | 6 |

| Maximum workpiece dimension | mm | 1250×2500 | 1250×4000 | 1250×5000 | 1500×5000 | 1250×4000 | 1500×4000 |

| Punching accuracy | mm | ±0. 1 | ±0. 1 | ±0. 1 | ±0. 1 | ±0. 1 | ±0. 1 |

| Turret die position (including 2 sets of self-rotating dies) | 32 | 32 | 32 | 32 | 32 | 32 | |

| Control shaft No. | Four (X, Y, T, C) | Four (X, Y, T, C) | Four (X, Y, T, C) | Four (X, Y, T, C) | Four (X, Y, T, C) | Four (X, Y, T, C) | |

| Weight | Ton | 14 | 16 | 18 | 19 | 20 | 22 |

Configuration Table

| 1. | Fanuc OI-PC special system for CNC punching machine | Fanuc (Japan) |

| 2. | AC digital servo amplifier | Fanuc (Japan) |

| 3. | AC digital servo motors | Fanuc (Japan) |

| 4. | Hydraulic system assembly | H+L company (German) |

| 5. | Precision ball screw assemblies | NSK (Japan) or Rexroth (German) |

| 6. | Precision liner of roller guide rail | THK (Japan) or Rexroth (German) |

| 7. | Pneumatic parts | SMC (Japan) or Festo (German) |

| 8. | Approach switches | Turck (German) |

| 9. | Tools | China |

| 10. | Auto-programming software | Radan (Britain) |

Related Names

Turret Punching Machine | Sheet Metal Turret Punch | CNC Metal Fabrication Tool

Links:https://globefindpro.com/products/81196.html

-

Semi-Automatic High Precision Chamfering Machine

Semi-Automatic High Precision Chamfering Machine

-

Tandem hydraulic press brake

Tandem hydraulic press brake

-

Drilling and Milling Machine

Drilling and Milling Machine

-

Automatic Double-column Band Saw

Automatic Double-column Band Saw

-

Hydraulic Surface Grinder

Hydraulic Surface Grinder

-

Taper Pipe End Forming Machine

Taper Pipe End Forming Machine

-

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

-

Gantry Type CNC Plasma Cutter

Gantry Type CNC Plasma Cutter

-

QC12Y/K Hydraulic Swing Beam Shearing Machine

QC12Y/K Hydraulic Swing Beam Shearing Machine

-

Portable CNC Plasma Cutter

Portable CNC Plasma Cutter

-

Vertical Band Saw

Vertical Band Saw

-

EMM21 Series C-Frame Fixed Bolster Mechanical Presses

EMM21 Series C-Frame Fixed Bolster Mechanical Presses