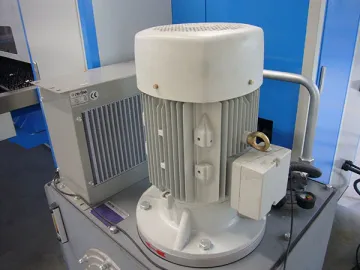

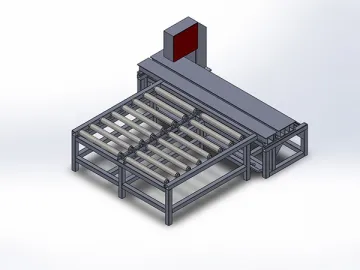

Semi-Automatic High Precision Chamfering Machine

Descriptions

The semi-automatic high precision chamfering machine is mainly used for cylindrical metal tube or round bar beveling. It is designed with hand feed, automatic clamping and auto feed clutch.

Mechanical Characteristics

1. The die clamping device and the cutter head are meticulously devised to ensure the centre lines of workpiece and cutter head are exactly consistent.

2. This equipment suffices to accomplish one-time uniform processing of tube end, tube external angle and internal angle.

3. Through taking advantage of belt pulley alternation, different levels of revolving speed can be achieved to perfectly process different metal materials and extend the cutter life.

4. The semi-automatic high precision chamfering machine is capable of two-stage feed for saving the working time. Besides, the adjustment is extremely convenient under slow-speed operation, making for more perfect processing.

Technical Parameters

| Item | PV52 | AC80 |

| Main motor power | 0.75KW | 2.2KW |

| Spindle speed | Adjustable according to different materials and belt pulley alteration. | |

| Workable tube diameter | 9-52 (mm) | 30-82 (mm) |

| Workable round bar diameter | 9-25 (mm) | 20-50 (mm) |

| Compressed air | 6-8kg/cm2 | 6-8kg/cm2 |

| 60ml/min. | 120ml/min. | |

| Standard configuration | 1. Main platform2. Clamp3. Standard cutter head4. A set of blade | |

| Special configuration | 1. Clamp of different specifications2. Special cutter holder and blade3. Special cutter head | |

Remark: For PV52, the special small cutter head and the special blade are necessary for processing tubes with 9-18mm diameter.

Related Names

Metal Pipe Beveling Machine | Steel Bar Chamfering Machine | Precision Metal Machining Tool

Links:https://globefindpro.com/products/81197.html

-

Tandem hydraulic press brake

Tandem hydraulic press brake

-

Drilling and Milling Machine

Drilling and Milling Machine

-

Automatic Double-column Band Saw

Automatic Double-column Band Saw

-

Hydraulic Surface Grinder

Hydraulic Surface Grinder

-

Taper Pipe End Forming Machine

Taper Pipe End Forming Machine

-

Pipe End/Bar End Double-Head Chamfering Machine

Pipe End/Bar End Double-Head Chamfering Machine

-

CNC Turret Punch Press

CNC Turret Punch Press

-

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

Hydraulic Three-Roller Symmetrical Plate Rolling Machine

-

Gantry Type CNC Plasma Cutter

Gantry Type CNC Plasma Cutter

-

QC12Y/K Hydraulic Swing Beam Shearing Machine

QC12Y/K Hydraulic Swing Beam Shearing Machine

-

Portable CNC Plasma Cutter

Portable CNC Plasma Cutter

-

Vertical Band Saw

Vertical Band Saw