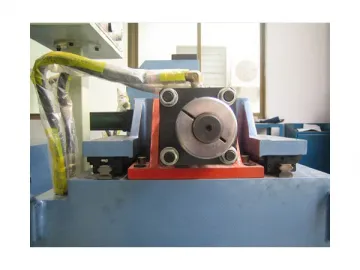

EM Series Single Head Pipe Bender

Packing Mode

Metal trunk

Features

1. The EM series single head pipe bender designed with microcomputer control and hydraulic drive enables the prefabrication of tubes in diversified bending angles.

2. It displays in English and comes with man-machine interaction. You can choose manual or semi-automatic operating mode.

3. The mobile foot switch has both starting up and emergency stop functions.

4. The imported hydraulic valve (Yuken of Japan) and the Nova oil pump (joint venture) are applied.

5. This product enables automatic counting and power-off memory function, so the data can be stored permanently. Meanwhile, the automatic core pulling and crease resisting devices make it more perfect.

6. The EM series single head pipe bender is equipped with a cooling system to ensure constant temperature and relatively equalizing pressure as well as robust tube bending.

7. The whole machine is highlighted by convenient operation, stable performance, high working efficiency and high security coefficient. It is an ideal choice for tube processing.

Applications

This product suits to process auto accessories like brake hoses, bumpers, mufflers, seats, etc. It is also applicable for multiple industries, such as motorcycle manufacturing, ship building, boiler, electric power, train, fitness equipment, air-conditioner, bicycle, steel furniture, sanitary ware, etc.

Technical Parameters

| Item | Unit | EM38 | EM50 | EM63 | EM75 | EM89 | EM100 |

| Maximum bending tube diameter × wall thickness | mm | Φ38×2 | Φ50×3 | Φ63×4 | Φ75×4 | Φ89×8 | Φ100×8 |

| Maximum bending radius (1) | mm | R260 | R350 | R350 | R400 | R450 | R500 |

| Minimum bending radius (2) | mm | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter |

| Maximum bending angle | Degree | 190 | |||||

| Standard core-through length* (3) | mm | 1600 | 2200 | 2600 | 2800 | 3500 | 3600 |

| Control system | Microcomputer control | ||||||

| Allowable bent tube number | Unit | 16 | |||||

| Storable component number (4) | Unit | 16×16 | |||||

| Motor | KW | 4 | 5.5 | 5.5 | 7.5 | 11 | 15 |

| Maximum system pressure | MPa | 12 | 12 | 12 | 12 | 14 | 14 |

| Hydraulic system control | Electromagnetic valve | ||||||

| Oil tank capacity | L | 110 | 150 | 220 | 250 | 260 | 300 |

| Overall dimension | mm | 2600×600×1000 | 3000×700×1030 | 3500×750×1100 | 4000×1000×1100 | 4550×1300×1300 | 5000×1600×1200 |

| Weight | kg | 750 | 1220 | 1500 | 2000 | 3500 | 5000 |

| Note: (1) and (3) are upon the specific requirements of customers. (2) depends on the tube diameter and (4) can be increased. | |||||||

| Item | Unit | EM110 | EM115 | EM130 | EM168 | EM189 | EM219 |

| Maximum bending tube diameter × wall thickness | mm | Φ110×8 | Φ115×10 | Φ130×8 | Φ168×14 | Φ189×14 | Φ219×16 |

| Maximum bending radius (1) | mm | R500 | R520 | R520 | R750 | R750 | R800 |

| Minimum bending radius (2) | mm | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter | Upon tube diameter |

| Maximum bending angle | Degree | 190 | |||||

| Standard core-through length* (3) | mm | 3700 | 4500 | 4500 | 5000 | 5500 | 6000 |

| Control system | Microcomputer control | ||||||

| Allowable bent tube number | Unit | 16 | |||||

| Storable component number (4) | Unit | 16×16 | |||||

| Motor | KW | 15 | 15 | 22 | 22 | 30 | 37 |

| Maximum system pressure | MPa | 14 | 14 | 14 | 16 | 16 | 16 |

| Hydraulic system control | Electromagnetic valve | ||||||

| Oil tank capacity | L | 320 | 350 | 400 | 650 | 700 | 800 |

| Overall dimension | mm | 5000×1400×1200 | 5500×1600×1200 | 6100×1600×1300 | 7100×2000×1800 | 8000×1800×1660 | 8800×2450×1980 |

| Weight | kg | 6000 | 7000 | 8000 | 15000 | 20000 | 35000 |

| Note: (1) and (3) are upon the specific requirements of customers. (2) depends on the tube diameter and (4) can be increased. | |||||||

Related Names

Steel Tube Bending Machine | Exhaust Pipe Bender | Aluminum Tubing Bender

Links:https://globefindpro.com/products/81216.html

-

Managed Switch with 4 Gigabit Ports and 3 SFP Slots

Managed Switch with 4 Gigabit Ports and 3 SFP Slots

-

10/100M Fast Switches Support Port-Based VLAN

10/100M Fast Switches Support Port-Based VLAN

-

Integrated T5 LED Tube for Series Connection

Integrated T5 LED Tube for Series Connection

-

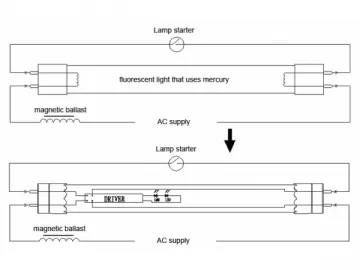

Ballast Compatible T8 LED Tube

Ballast Compatible T8 LED Tube

-

Dustproof T5 LED Tube with Double Protection Cover

Dustproof T5 LED Tube with Double Protection Cover

-

Height Adjustable Study Desk and Chair

Height Adjustable Study Desk and Chair

-

Hydraulic Automatic Pipe End Forming Machine

Hydraulic Automatic Pipe End Forming Machine

-

Aluminum Cutting Circular Saw

Aluminum Cutting Circular Saw

-

Scissor Action Horizontal Band Saw

Scissor Action Horizontal Band Saw

-

Vertical Drilling Machine

Vertical Drilling Machine

-

Servo Feed Automatic Pipe Cutting Circular Saw

Servo Feed Automatic Pipe Cutting Circular Saw

-

Adjustable Cutting Angle Hydraulic Notching Machine

Adjustable Cutting Angle Hydraulic Notching Machine