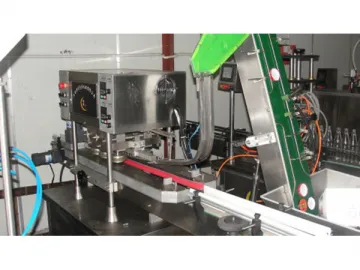

Double Side Labeling Machine

With the following parts, YXT-C double side labeling machine is a stable, reliable and automatic labeler with accurate labeling. It can be used alone, or used in the production line.

Main Parts: Synchrostepor servo motor, frequency converter, touch screen, PLC control system, Japanese photoelectric switch, large torque step motor, etc.

Materials

This labels equipment is made as requested by GMP. It applies the aluminum alloy and 304 or 316 stainless steel as the raw materials. All of its parts are made with the standardized design.

Features of the Double Side Labeling Machine

1. As a self adhesive sticker labeling machine, this product is suitable for all kinds of bottles in plentiful industries, including medicines, chemicals, food, etc.

2. It makes use of the label feeding method of overseas counterparts, thus avoiding the problem such as unstable labeling.

3. One unit of such industrial labelling system can meets the labeling requirements of two production lines.

Working Principle of the Double Side Labeling Machine

1. Lay the objects onto the conveyer belt. The correction device on the belt will correct the position of those objects. Once the sensor detects the objects, it will send signals to the label control system.

2. When the objects arrive to the suitable position, the controlling system controls the motor so as to send out and attach the labels onto both sides of the objects.

Parameters of the Double Side Labeling Machine

| Inner Diameter of Label Roll | 76mm |

| Max. Outer Diameter of Label Roll | 300mm |

| Size of Label | Width: 10 –150mm; Length: 20 –250mm |

| Labeling Precision | ±1mm |

| Size of Bottle | Diameter: 20-150mm; Height: 30-300mm |

| Productivity | 30 – 100 bottles per minute |

| Power Supply | 220V - 50Hz/60Hz |

| Power Consumption | 750W |

| Weight | 500kg |

| Overall Dimensions | 2,500mm*1,500mm*1,400mm |

Links:https://globefindpro.com/products/81587.html

-

Roll-over Bottle Rinser

Roll-over Bottle Rinser

-

Automatic Screw Capping Machine

Automatic Screw Capping Machine

-

Automatic Round Bottle Labeling Machine

Automatic Round Bottle Labeling Machine

-

Automatic Single Head Aluminum Capping Machine

Automatic Single Head Aluminum Capping Machine

-

Two Tunnel Pellet Counting and Filling Machine

Two Tunnel Pellet Counting and Filling Machine

-

Small Round Bottle Labeling Machine

Small Round Bottle Labeling Machine

-

Isobaric Bottling Line

Isobaric Bottling Line

-

Air-Cooled Aluminum Foil Sealing Machine

Air-Cooled Aluminum Foil Sealing Machine

-

Flat Bottle Labeling Machine

Flat Bottle Labeling Machine

-

Four Filling Head Capping Machine

Four Filling Head Capping Machine

-

Automatic Press Capping Machine

Automatic Press Capping Machine

-

Carton Sealer

Carton Sealer