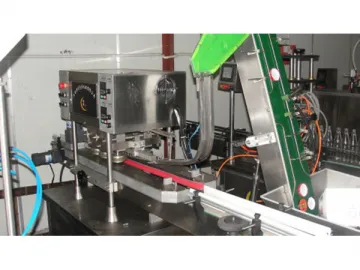

Roll-over Bottle Rinser

Working Principle of the Roll-over Bottle Rinser

1. YXT-CP-30 roll-over bottle rinser can act as a beverage system cleaner. Unwashed bottles are driven by the bottle conveyor chain. Each bottle is separated by a fixed distance via spiral displacement. Once in place, these bottles are pushed into the bottle clamp by the wheel mechanism.

2. A clamp of the bottle washing machine affixes onto the bottle neck before turning 90 degrees on the rail to align the bottle mouth with the spray nozzle. After entering the initial area for interior and exterior rinsing, the bottles are then ushered into the drip-dry area.

3. When most of the water has been emptied from the bottle cleaning equipment, the bottles are brought into the second rinsing area for interior cleansing. The rinsed bottles are then conveyed into the blow-dry area for drying. Clean bottles are brought down by the clamp and prepared for further processing.

Parameters of the Roll-over Bottle Rinser

| Model | CP-30 | CP-24 | CP-16 |

| Bottles per Time | 30 | 24 | 16 |

| Productivity | 6, 000 bottles/h | 4, 500 bottles/h | 3, 000 bottles/h |

| Bottle Height | 240-280mm | 240-380mm | 240-380mm |

| Power | 2.6kw | 2.2kw | 1.5kw |

| Overall Dimensions | 1, 650*1, 850*1,900mm | 1, 550*1, 550*1,900mm | 1, 350*1, 300*1,900mm |

Links:https://globefindpro.com/products/81588.html

-

Automatic Screw Capping Machine

Automatic Screw Capping Machine

-

Automatic Round Bottle Labeling Machine

Automatic Round Bottle Labeling Machine

-

Automatic Single Head Aluminum Capping Machine

Automatic Single Head Aluminum Capping Machine

-

Two Tunnel Pellet Counting and Filling Machine

Two Tunnel Pellet Counting and Filling Machine

-

Small Round Bottle Labeling Machine

Small Round Bottle Labeling Machine

-

8 Head Filling and Capping Machine

8 Head Filling and Capping Machine

-

Double Side Labeling Machine

Double Side Labeling Machine

-

Isobaric Bottling Line

Isobaric Bottling Line

-

Air-Cooled Aluminum Foil Sealing Machine

Air-Cooled Aluminum Foil Sealing Machine

-

Flat Bottle Labeling Machine

Flat Bottle Labeling Machine

-

Four Filling Head Capping Machine

Four Filling Head Capping Machine

-

Automatic Press Capping Machine

Automatic Press Capping Machine