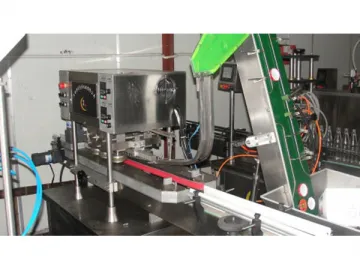

Automatic Screw Capping Machine

Working Principle

1. YXT-CG automatic screw capping machine is a screw capper developed by KUIXING. Bottles access to the conveyer belt from the last process, while the cap automatically gets to the bottle mouth under the function of the automatic capping machine.

2. During the forward moving of the bottles, the caps will be automatically screwed by the capping machine which is independently controlled by three groups of stepless variable-frequency and variable-speed motor.

Features of the Automatic Linear Screw Capping Machine

1. This automatic screw capping machine applies the new design concept such as flexible module combination. It is applicable to a variety of bottles and caps.

2. It just needs simple adjustment, and you don’t have to replace the parts. Our machine is easily operated and conveniently maintained.

3. The torque can be individually adjusted to ensure the tight screwing. The capper has a clutch device which can help avoid the damage to caps.

4. With two sets of bottle clamping ring, our automatic screw capping machine is also suitable for high bottles or unstable bottles.

5. The speed of cap sorter, conveyor, cap screwing machine, and bottle clamping belt can be separately adjusted.

6. This equipment is designed in accordance with the GMP standards.

7. Optional Device: automatic capping machine and caps storage hopper.

Applicable Industries

This automatic screw capping machine is designed for different caps in the sectors, including food, pharmacy, daily use chemical, farm chemicals, etc. It can act as either pharma machinery or food packaging machinery.

Parameters of the Automatic Linear Screw Capping Machine

| Size of Bottle | φ20-150mm |

| Size of Cap | φ12-70mm |

| Qualification Rate of Capping | ≥99% |

| Power Supply | 220V 50Hz |

| Power Consumption | ≤1Kw |

| Speed Control | Frequency control |

| Weight | 850kg |

Links:https://globefindpro.com/products/81589.html

-

Automatic Round Bottle Labeling Machine

Automatic Round Bottle Labeling Machine

-

Automatic Single Head Aluminum Capping Machine

Automatic Single Head Aluminum Capping Machine

-

Two Tunnel Pellet Counting and Filling Machine

Two Tunnel Pellet Counting and Filling Machine

-

Small Round Bottle Labeling Machine

Small Round Bottle Labeling Machine

-

8 Head Filling and Capping Machine

8 Head Filling and Capping Machine

-

Single Side Labeling Machine

Single Side Labeling Machine

-

Roll-over Bottle Rinser

Roll-over Bottle Rinser

-

Double Side Labeling Machine

Double Side Labeling Machine

-

Isobaric Bottling Line

Isobaric Bottling Line

-

Air-Cooled Aluminum Foil Sealing Machine

Air-Cooled Aluminum Foil Sealing Machine

-

Flat Bottle Labeling Machine

Flat Bottle Labeling Machine

-

Four Filling Head Capping Machine

Four Filling Head Capping Machine