Steel Coil Mini Shearing

We mainly provide the small steel shearing processing service to the customers engaged in small household electrical appliance manufacturing. The electro-galvanized steel plate predominates in our small steel plate products for manufacturing microwave oven liner, automobile filter, outer shell of television set-top box, etc.

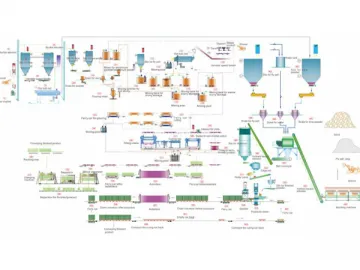

Small Cut-to-length Processing Flow

Uncoiling --- Stretching-bending Rectifying --- Cleaning --- Shearing --- Inspection --- Packaging

1. Uncoiling: Remove the steel coil package, and put the steel coil onto the shearing equipment with the help of crane.

2. Stretching-bending Rectifying: The steel plate position needs to be rectified to guarantee the position accuracy before shearing. Then, the shearing precision can be ensured.

3. Cleaning: Clean up the dust or other contaminants on the surface of steel plate.

4. Shearing: Shear the steel plate in line with the size that the customer requests.

5. Inspection: The quality controller checks the surface quality of the sheared steel plate.

6. Packaging: The processed steel plate is packaged by weight or quantity that customer requests.

Material

We can process the steel coil with the material covering cold rolled steel, electro-galvanized steel, hot-dipped galvanized steel, galvalume steel, color coated steel, electrical steel, stainless steel, etc.

Specification of Small Cut-to-length Line

| Thickness of Material | 0.3 mm~2.5 mm |

| Width of Material | < 800 mm |

| Length of Shearing | 220 mm~5000 mm |

| Length Tolerance | ± 0.3 mm |

| Max. Shear Strength | 560 N/mm |

| Max. Yield Strength | 420 N/mm |

| Max. Production Line Speed | 80 m/min |

| Max. Coil Weight | < 5 MT |

| Outside Diameter of Steel Coil | < 1500 mm |

| Inside Diameter of Steel Coil | 508mm / 610 mm |

| Processing Capacity | 50,000 MT/year |

| Shear Mode | Flying Shear |

Our product has the comparative advantage. The all-round service is also available to customers.

Related Names

Sheet Metal Blanking Process | Steel Plate Cutter | Steel Coil Slitting Machine

Links:https://globefindpro.com/products/81789.html

-

Aluminized Steel Sheet (ALCOT)

Aluminized Steel Sheet (ALCOT)

-

Carbon Steel Pipe (ERW,SSAW,API 5L)

Carbon Steel Pipe (ERW,SSAW,API 5L)

-

Hydraulic Press C

Hydraulic Press C

-

Clamping Machine

Clamping Machine

-

AAC Block & Sand-lime Brick Production Line

AAC Block & Sand-lime Brick Production Line

-

Machine for Steel Pin Drawing

Machine for Steel Pin Drawing

-

100cm C Band Satellite Dish

100cm C Band Satellite Dish

-

150cm Ku Band Satellite Dish

150cm Ku Band Satellite Dish

-

85cm Ku Band Satellite Dish

85cm Ku Band Satellite Dish

-

120cm C Band Satellite Dish

120cm C Band Satellite Dish

-

45cm Ku Band Satellite Dish

45cm Ku Band Satellite Dish

-

Pre-Painted Galvanized Steel Coil (PPGI)

Pre-Painted Galvanized Steel Coil (PPGI)