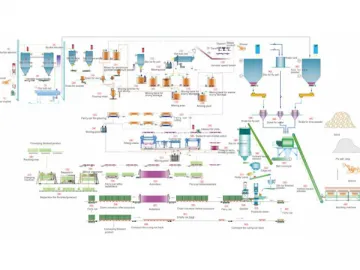

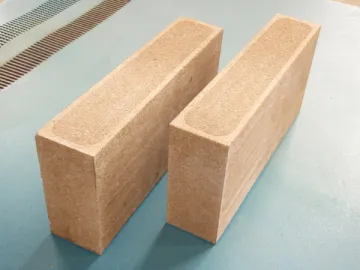

AAC Block & Sand-lime Brick Production Line

The AAC block and sand-lime brick production line is suitable for making AAC panels, AAC blocks, and sand-lime bricks. Wastes from this process can be recycled immediately, which reduces the use of raw material and saves cost.

Features

1. This production line provides the combined advantages of AAC block production line and sand-lime brick production line. Our company is the only one inChinathat can provide a combined AAC block and sand-lime brick production line.

2. This combined AAC block and sand-lime brick production line is designed to produce a variety of sand-lime concrete products to fit diversified market demands. It also provides customer companies with the ability to be more responsive to the market change.

3. The sand-lime brick production process and AAC block production line can share ball mill, boiler, and partially an autoclave. This comes with financial benefits, since users do not need to purchase two ball mills, boilers, or autoclaves. It also minimizes the factory space needed to accommodate the production line, thus saving factory construction cost. Meanwhile, sharing production equipment also means reduced amount of steam needed.

4. A few waste bricks might be left after the production process. These bricks will be crushed into aggregates, which can then be added to the autoclave for repeated use. Turning wastes into valued raw material helps customers achieve significant cost savings.

Related Names

Building Concrete Block Equipment | AAC Block Making Machine | Concrete Brick Manufacturing Equipment

Links:https://globefindpro.com/products/81795.html

-

Machine for Steel Pin Drawing

Machine for Steel Pin Drawing

-

60cm Ku Band Satellite Dish

60cm Ku Band Satellite Dish

-

Machine for Frame Seat Cycling

Machine for Frame Seat Cycling

-

120cm Ku Band Satellite Dish

120cm Ku Band Satellite Dish

-

210cm C Band Satellite Dish

210cm C Band Satellite Dish

-

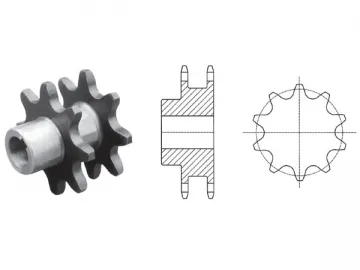

High Speed Conveyor Chain Sprocket

High Speed Conveyor Chain Sprocket

-

Clamping Machine

Clamping Machine

-

Hydraulic Press C

Hydraulic Press C

-

Carbon Steel Pipe (ERW,SSAW,API 5L)

Carbon Steel Pipe (ERW,SSAW,API 5L)

-

Aluminized Steel Sheet (ALCOT)

Aluminized Steel Sheet (ALCOT)

-

Steel Coil Mini Shearing

Steel Coil Mini Shearing

-

100cm C Band Satellite Dish

100cm C Band Satellite Dish