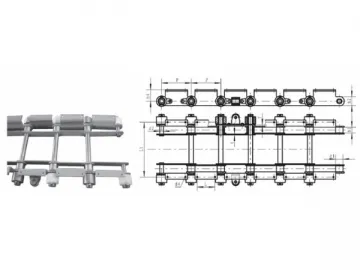

Conveyor Chain for Paper Roll

This series of conveyor chain is frequently utilized in papermaking industry for paper roll conveying applications.

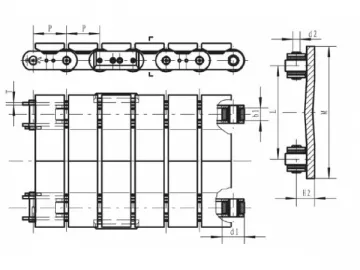

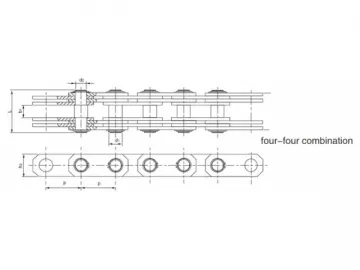

Its top plates are welded onto the chain. In order to ensure welding quality and a flat surface created by the top plates, we adopt multi-station automatic welding machine to perform synchronous welding to multiple welding spots. Thus, the deformation caused by regional welding is minimized. Meanwhile, the top plates are cold drawn so that smooth finish and surface evenness are guaranteed.

Our paper roll conveyor chain comes with extended service life due to the following designs. Firstly, it is designed with additional SF1 shaft sleeves between the pin and the bushing. Secondly, at the both ends of pins, there are specialized bearings with arc shaped outer ring.

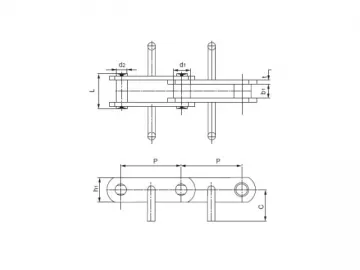

Technical Specifications

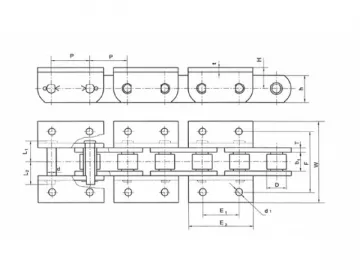

| Chain no. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Length of pin b2 (mm) | Thickness of sidebar t (mm) | Height of top plate h1 (mm) | Length of top plate m (mm) | Tensile strength q (KN) |

| 63PF2 | 63 | 130 | 30 | 20 | 213 | 6 | 50 | 220 | 176 |

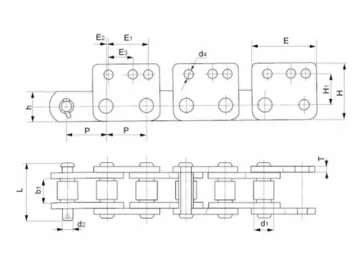

| Chain no. | Pitch P (mm) | Inner width of inner link b1 (mm) | Diameter of roller d1 (mm) | Diameter of pin d2 (mm) | Central distance between two links L (mm) | Thickness of sidebar t (mm) | Height of top plate h1 (mm) | Length of top plate m (mm) | Tensile strength q (KN) |

| 63PF | 63 | 24 | 42 | 14 | 179 | 5 | 34.5 | 250 | 160 |

Related Names

Flat Top Chain | Paper Mill Chain | Single Roller Chain

Links:https://globefindpro.com/products/81843.html

-

Other Chain for Sugar Industry

Other Chain for Sugar Industry

-

Straight Side Plate Chain for Sugar Industry

Straight Side Plate Chain for Sugar Industry

-

Forged Caterpillar Drive Chain

Forged Caterpillar Drive Chain

-

Steel Draw Bench Chain

Steel Draw Bench Chain

-

Forged Scraper Chain

Forged Scraper Chain

-

Scraper Chain for Grain Machines (Welded Steel Chain)

Scraper Chain for Grain Machines (Welded Steel Chain)

-

Trencher Chain

Trencher Chain

-

Conveyor Chain for Automobile Industry

Conveyor Chain for Automobile Industry

-

Heavy Duty Offset Sidebar Roller Chain

Heavy Duty Offset Sidebar Roller Chain

-

DF3500 and DF3498 Type Offset Link Chain

DF3500 and DF3498 Type Offset Link Chain

-

Forged Drive Chain

Forged Drive Chain

-

FU Style Conveyor Chain

FU Style Conveyor Chain