Steel Draw Bench Chain

This range of drive chain is designed to drag the steel draw bench which is commonly used in steel plants, steel pipe making plants, structural steel cold drawing plants, as well as many other industrial uses. It is applicable for carrying of high impact load under low speed conditions.

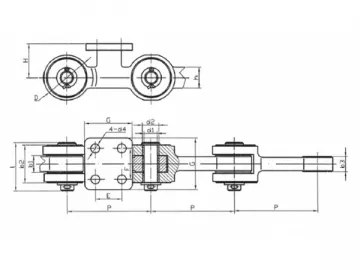

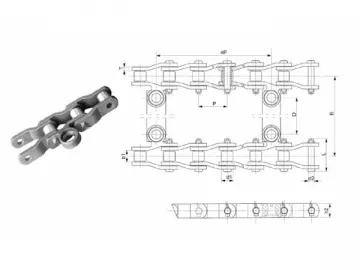

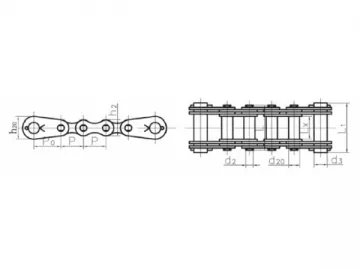

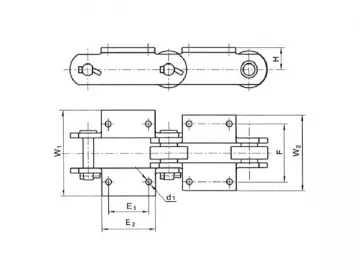

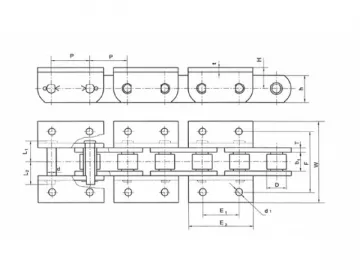

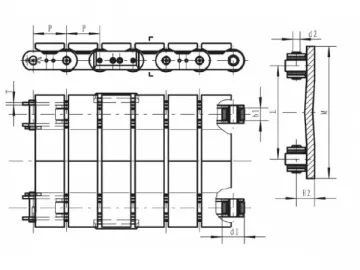

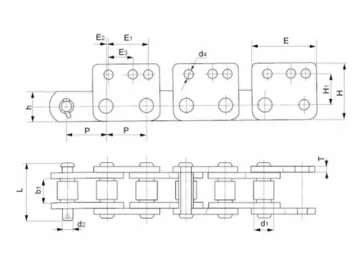

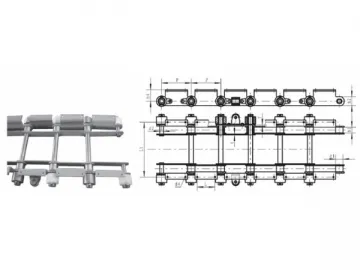

The steel draw bench chain features simple and rational structure design. It primarily consists of the chain plate and the pin.

The chain plates or sidebars are made using spring steel alloys with high fatigue resistance. After integral hardening and tempering, the sidebars are created with a hole at each end by a precision boring machine. The precision machining center ensures exactly the same hole pitch and bore size, thus allowing each sidebar to carry equal load.

The pin rolls also undergo integral hardening and tempering, as well as precision processing for the same external diameter. Thereafter, they are processed by high frequency induction heating treatment to increase surface hardness, and are precision ground to offer smooth finish. Due to these processes for the pins and side plates, the steel draw bench chain is provided with improved lifespan.

Technical Specifications

| Chain no. | Pitch P (mm) | Inner width of inner link b1 (max.) (mm) | Diameter of pin (max.) (mm) | Length of pin L (max.) (mm) | Height of sidebar h2 (max.) (mm) | Thickness of sidebar T (mm) | Combination of sidebars n*n | Allowed working tension (KN) | |

| d2 (max.) (mm) | d1 (max.) (mm) | ||||||||

| P100-10T | 100 | 47 | 30 | 39.5 | 121 | 63.5 | 12.7 | 2*2 | 10 |

| P100-15T | 100 | 50 | 40 | 45 | 150 | 80 | 18 | 2*2 | 15 |

| P103.2-10T | 103.2 | 52 | 32 | 46 | 142 | 70 | 16 | 2*2 | 10 |

| P103.2-10T | 103.2 | 55 | 36 | 44 | 137 | 80 | 16 | 2*2 | 10 |

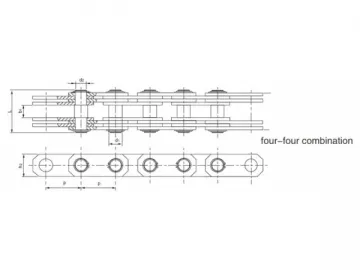

| P120-10T-A | 120 | 53 | 35 | 39.5 | 176 | 75 | 12 | 4*4 | 10 |

| P120-10T-B | 120 | 53 | 35 | 40 | 169 | 75 | 12 | 4*4 | 10 |

| P120-10T-C | 120 | 50 | 35 | 49 | 171 | 75 | 12 | 4*4 | 10 |

| P120-10T-D | 120 | 53 | 35 | 40 | 192 | 75 | 14 | 4*4 | 10 |

| P120-15T | 120 | 56 | 42 | 54 | 179 | 100 | 12 | 4*4 | 15 |

| P125-10T | 125 | 52 | 25 | 30 | 122 | 60 | 10 | 2*2 | 10 |

| P125-20T | 125 | 60 | 40 | 49 | 186 | 100 | 12 | 4*4 | 20 |

| P134-10T | 134 | 50 | 44 | 49.5 | 175 | 80 | 12 | 4*4 | 10 |

| P135 | 135 | 50 | 45 | 49.5 | 175 | 75 | 12 | 4*4 | |

| P140 | 140 | 64.5 | 45 | 54.5 | 184.5 | 100 | 12 | 4*4 | |

| P140-10T | 140 | 50 | 45 | 54 | 148 | 100 | 18 | 2*2 | 10 |

| P140-15T-A | 140 | 50 | 35 | 44.5 | 158 | 80 | 10 | 4*4 | 15 |

| P140-15T-B | 140 | 65 | 55 | 63 | 192 | 120 | 12 | 4*4 | 15 |

| P140-15T-C | 140 | 75 | 55 | 64 | 216 | 120 | 14 | 4*4 | 15 |

| P140-20T-A | 140 | 68 | 48 | 65 | 190.6 | 122 | 12 | 4*4 | 20 |

| P140-20T-B | 140 | 80 | 55 | 64.5 | 221 | 120 | 14 | 4*4 | 20 |

| P140-5T | 140 | 53 | 38 | 44 | 159 | 75 | 10 | 4*4 | 5 |

| P148-10T-A | 148 | 70 | 50 | 59.5 | 176 | 100 | 10 | 4*4 | 10 |

| P148-10T-B | 148 | 70 | 55 | 69.5 | 176 | 100 | 10 | 4*4 | 10 |

| P148-15T | 148 | 80 | 60 | 69.5 | 203 | 100 | 12 | 4*4 | 15 |

| P150-10T | 150 | 60 | 45 | 50 | 215 | 95 | 16 | 4*4 | 10 |

| P150-20T | 150 | 70 | 45 | 50 | 195 | 100 | 12 | 4*4 | 20 |

| P154-15T | 154 | 52 | 50 | 59 | 176 | 100 | 12 | 4*4 | 15 |

| P154-20T-A | 154 | 65 | 50 | 59 | 190 | 100 | 12 | 4*4 | 20 |

| P154-20T-B | 154 | 65 | 50 | 59 | 205 | 100 | 14 | 4*4 | 20 |

| P160 | 160 | 60 | 55 | 59 | 192 | 100 | 12 | 4*4 | |

| P160-20T | 160 | 68 | 55 | 60 | 210 | 120 | 14 | 4*4 | 20 |

| P178-20T | 178 | 84 | 60 | 88.5 | 213 | 120 | 12 | 4*4 | 20 |

| P180-10T-A | 180 | 60 | 40 | 49 | 186 | 100 | 12 | 4*4 | 10 |

| P180-10T-B | 180 | 66 | 45 | 54 | 192 | 90 | 12 | 4*4 | 10 |

| P180-10T-C | 180 | 52 | 38 | 44 | 178 | 100 | 12 | 4*4 | 10 |

| P180-10T-D | 180 | 60 | 38 | 44 | 182 | 100 | 12 | 4*4 | 10 |

| P180-10T-E | 180 | 52 | 38 | 44 | 182 | 85 | 12 | 4*4 | 10 |

| P180-10T-F | 180 | 52 | 40 | 44 | 178 | 100 | 12 | 4*4 | 10 |

| P180-10T-G | 180 | 52 | 40 | 50 | 172 | 90 | 12 | 4*4 | 10 |

| P180-10T-H | 180 | 60 | 45 | 49 | 184 | 100 | 12 | 4*4 | 10 |

| P180-10T-I | 180 | 60 | 45 | 50 | 180 | 100 | 12 | 4*4 | 10 |

| P180-20T-A | 180 | 70 | 60 | 69 | 227 | 120 | 16 | 4*4 | 20 |

| P180-20T-B | 180 | 70 | 60 | 70 | 227 | 120 | 16 | 4*4 | 20 |

| P180-20T-C | 180 | 68 | 60 | 69 | 210 | 120 | 14 | 4*4 | 20 |

| P180-20T-D | 180 | 70 | 60 | 68 | 227 | 120 | 16 | 4*4 | 20 |

| P180-20T-E | 180 | 70 | 60 | 68 | 230 | 120 | 16 | 4*4 | 20 |

| P180-20T-F | 180 | 66 | 60 | 69 | 223 | 120 | 16 | 4*4 | 20 |

| P180-20T-G | 180 | 66 | 60 | 69 | 223 | 120 | 16 | 4*4 | 20 |

| P180-20T-H | 180 | 66 | 60 | 69.5 | 223 | 120 | 16 | 4*4 | 20 |

| Chain no. | Pitch P (mm) | Inner width of inner link b1 (max.) (mm) | Diameter of pin (max.) (mm) | Length of pin L (max.) (mm) | Height of sidebar h2 (max.) (mm) | Thickness of sidebar T (mm) | Combination of sidebars n*n | Allowed working tension (KN) | |

| d2 (max.) (mm) | d1 (max.) (mm) | ||||||||

| P180-20T-I | 180 | 66 | 60 | 70 | 226 | 120 | 16 | 4*4 | 20 |

| P180-20T-J | 180 | 80 | 60 | 70 | 241 | 120 | 16 | 4*4 | 20 |

| P180-20T-K | 180 | 65 | 60 | 69.5 | 236 | 120 | 18 | 4*4 | 20 |

| P180-20T-L | 180 | 67 | 60 | 68 | 241 | 120 | 18 | 4*4 | 20 |

| P180-30T-A | 180 | 66 | 60 | 70 | 223 | 120 | 16 | 4*4 | 30 |

| P180-30T-B | 180 | 70 | 65 | 78 | 200 | 120 | 12 | 4*4 | 30 |

| P180-30T-C | 180 | 82 | 60 | 69.5 | 273 | 120 | 20 | 4*4 | 30 |

| P180-40T-A | 180 | 66 | 60 | 68 | 223 | 120 | 16 | 4*4 | 40 |

| P180-40T-B | 180 | 80 | 65 | 69.5 | 236 | 130 | 16 | 4*4 | 40 |

| P180-45T | 180 | 78.4 | 60 | 69.5 | 236.4 | 120 | 16 | 4*4 | 45 |

| P180-50T | 180 | 68 | 60 | 69 | 243 | 120 | 18 | 4*4 | 50 |

| P190-30T | 190 | 66 | 70 | 80 | 242 | 120 | 16 | 4*4 | 30 |

| P190-40T | 190 | 92 | 70 | 80 | 326 | 120 | 16 | 6*6 | 40 |

| P190-45T | 190 | 75 | 60 | 70 | 264 | 120 | 20 | 4*4 | 45 |

| P200-40T | 200 | 85 | 65 | 74 | 240 | 130 | 16 | 4*4 | 40 |

| P200-45T-A | 200 | 90 | 70 | 79 | 300 | 140 | 20 | 4*4 | 45 |

| P200-45T-B | 200 | 85 | 65 | 73 | 261 | 130 | 18 | 4*4 | 45 |

| P200-45T-C | 200 | 85 | 65 | 74.5 | 261 | 130 | 18 | 4*4 | 45 |

| P200-45T-D | 200 | 85 | 65 | 74.5 | 277 | 130 | 20 | 4*4 | 45 |

| P200-45T-E | 200 | 85 | 60 | 73 | 275 | 120 | 20 | 4*4 | 45 |

| P200-45T-F | 200 | 85 | 65 | 73.5 | 277 | 120 | 20 | 4*4 | 45 |

| P200-45T-G | 200 | 90 | 60 | 69 | 287 | 130 | 20 | 4*4 | 45 |

| P220-35T | 220 | 90 | 70 | 90 | 296 | 140 | 20 | 4*4 | 35 |

| P220-45T | 220 | 80 | 70 | 78 | 272 | 130 | 20 | 4*4 | 45 |

| P220-65T-A | 220 | 90 | 70 | 78 | 297 | 140 | 22 | 4*4 | 65 |

| P220-65T-B | 220 | 100 | 75 | 84 | 290 | 160 | 20 | 4*4 | 65 |

| P220-75T | 220 | 100 | 75 | 84 | 307 | 150 | 22 | 4*4 | 75 |

| P250 | 250 | 100 | 70 | 80 | 342 | 150 | 25 | 4*4 | |

| P250-100T-A | 250 | 100 | 85 | 98 | 317 | 200 | 22 | 4*4 | 100 |

| P250-100T-B | 250 | 100 | 85 | 100 | 305 | 200 | 22 | 4*4 | 100 |

| P250-100T-C | 250 | 101 | 80 | 88 | 339 | 160 | 25 | 4*4 | 100 |

| P250-120T | 250 | 110 | 85 | 95 | 361 | 190 | 18 | 6*6 | 120 |

| P250-65T-A | 250 | 100 | 75 | 84 | 304 | 150 | 22 | 4*4 | 65 |

| P250-65T-B | 250 | 100 | 75 | 84 | 308 | 150 | 22 | 4*4 | 65 |

| P250-65T-C | 250 | 100 | 75 | 84 | 307 | 150 | 22 | 4*4 | 65 |

| P250-65T-D | 250 | 100 | 75 | 85 | 306 | 150 | 22 | 4*4 | 65 |

| P250-65T-E | 250 | 100 | 75 | 84 | 330 | 150 | 25 | 4*4 | 65 |

| P250-65T-F | 250 | 100 | 75 | 88 | 332 | 150 | 25 | 4*4 | 65 |

| P250-75T-A | 250 | 100 | 70 | 79.5 | 327 | 150 | 23.2 | 4*4 | 75 |

| P250-75T-B | 250 | 100 | 70 | 79.5 | 342 | 150 | 25 | 4*4 | 75 |

| P250-80T | 250 | 108 | 70 | 80 | 382 | 150 | 20 | 6*6 | 80 |

| P250-75T | 260 | 100 | 90 | 108 | 312 | 180 | 22 | 4*4 | 75 |

| P280-100T | 280 | 115 | 100 | 118 | 351 | 200 | 25 | 4*4 | 100 |

| P300-120T | 300 | 125 | 85 | 98 | 425 | 180 | 22 | 6*6 | 120 |

| P300-150T-A | 300 | 145 | 100 | 108 | 425 | 200 | 20 | 6*6 | 150 |

| P300-150T-B | 300 | 120 | 100 | 118 | 406 | 200 | 20 | 6*6 | 150 |

| P300-150T-C | 300 | 115 | 100 | 118 | 401 | 220 | 30 | 4*4 | 150 |

| P80-10T | 80 | 36 | 30 | 35 | 142 | 60 | 10 | 4*4 | 10 |

Application Cases

| Draw Bench Chain Utilized in Steel Pipe Processing Industry |

Related Names

Solid Bearing Pin Chain | Industrial Roller Chain | Cold Drawn Machine Chain

Links:https://globefindpro.com/products/81847.html

-

Forged Scraper Chain

Forged Scraper Chain

-

Scraper Chain for Grain Machines (Welded Steel Chain)

Scraper Chain for Grain Machines (Welded Steel Chain)

-

Conveyor Chain for Sugar Industry

Conveyor Chain for Sugar Industry

-

Paver Chain

Paver Chain

-

Hollow Pin Leaf Chain

Hollow Pin Leaf Chain

-

Chain Attachments for Sugar Industry

Chain Attachments for Sugar Industry

-

Forged Caterpillar Drive Chain

Forged Caterpillar Drive Chain

-

Straight Side Plate Chain for Sugar Industry

Straight Side Plate Chain for Sugar Industry

-

Other Chain for Sugar Industry

Other Chain for Sugar Industry

-

Conveyor Chain for Paper Roll

Conveyor Chain for Paper Roll

-

Trencher Chain

Trencher Chain

-

Conveyor Chain for Automobile Industry

Conveyor Chain for Automobile Industry