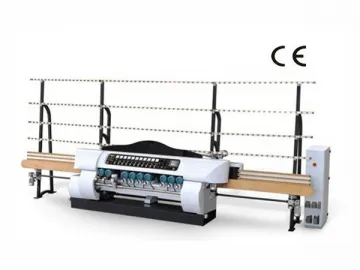

RBL261B/361B/371B Glass Straight Line Bevelling Machine (PLC)

This PLC controlled glass straight line bevelling machine is designed to finish rough grinding, fine grinding, hemline grinding, as well as polishing treatment for flat glass, and it includes three models which are RBL261B, RBL361B and RBL371B.

Features

1. A coarse pitch chain is adopted to transport the glass, and the steady delivering performance contributes to the precise result.

2. The rear transferring board is equipped with an automatic cleaning device to keep it clean all the time.

3. Thanks to the manual lubrication system, this glass straight line bevelling machine is able to work under good lubrication conditions.

4. With the help of PLC control system, both automatic control and manual control are realized. On the human-machine interface, users can set relevant parameters, such as bevel width, original glass thickness, remaining glass thickness after processing, etc.

5. By lifting and descending the back guide rail, the fall between front and back guide rails is adjusted. As a result, larger glass panels are applicable, and the processing specification is also enlarged.

6. Because of the high rigidity, stable performance, high yield rate as well as superb precision of lifting and descending, this glass straight line bevelling machine fits for batch production of glass mosaic.

Major Technical Parameters

1. Power supply: 380V / 50Hz

2. Speed range: 0.4-5m/min

3. Min. glass size: 30×30mm

4. Max. glass size: 3000×3000mm

5. Glass thickness: 3-19mm

6. Angle range: 3°- 45°

7. Max. bevel width: 40mm for RBL261B and RBL361B, 50mm for RBL371B.

8. Power: 24.3kW, 26.5kW and 28kW for RBL261B/361B/371B, respectively.

9. Overall dimensions (L×W×H): 6800×1000×2500mm

10. Worktable height: 850mm

Major Components

| Item | Descriptions |

| Machine and frame | The base, upright column, cross beam, grinding head, front and back guide rails are all constructed by welding high quality steel plates, and then high temperature annealing treatment is applied for a long time. Finally, rough machining and fine machining are carried out. Thus, these parts possess large loading capacity which makes them be able to provide stable performance. |

| Front and back platens | These platens are made of 40Cr steel, and the friction surfaces receive fine grinding after high frequency quenching treatment, making them more durable. |

| Grinding head 9# and 10# | They are pneumatically polished by the high precision linear slide rail to offer better result. |

| Motor for grinding head | Shanghai ABB motor or Shanghai CDQC motor is equipped, and these products can provide stable performance with low failure rate. |

| Water pump | Hunan Shanqing brand |

| Variable frequency motor | The main transmission uses a variable frequency motor that is supplied by Zhengjiang Xinling Motor Co., Ltd. (former Huangyan Motor Factory), and a big torque reducer is also applied. Meanwhile, the linkage between front and back guide rails is achieved with the help of a big modulus gear box, realizing more stable transmission when grinding bevel edge and thick glass. |

| Pendulum seat | It adopts screw rod rear support structure to improve grinding rigidity. |

| Screw rod for front guide rail | The nut is installed at the side face of upright column to facilitate maintenance jorb. |

| Output delivery | The guide rail is equipped with guiding devices for small glass panels to protect the glass from being stuck to back board during grinding process. |

| Transmission worm gear box | Zhujiang brand |

| Bearing | HRE: Harbin Ruiha Beaing Co., Ltd. |

| Glass support shelf | It is made of aluminum alloy. |

| Timing belt | A famous Sino-American joint venture: Yongli |

| Transducer | Emerson, USA |

| Rotary switch and emergency stop | These parts are supplied by Jiangyin Changjiang Electric Appliance Co., Ltd. and Guangzhou Benlee Industrial Switch Manufacture Co., Ltd. |

| Photoelectric switch and intermediate relay | Omron, Japan |

| PLC | Delta, Taiwan |

| Human-machine interface | Hitech, Taiwan |

| Rotary encoder | Autonics, Korea |

| Transformer, contactor, and low voltage circuit breaker | Juche Electric Appliances Co., Ltd., and CHINT Electronics Co., Ltd. |

Grinding Wheel Layout and Technical Parameters for RBL261B

| Item | Grinding head 1# (rough grinding) | Grinding head 2# (rough grinding) | Grinding head 3# (rough grinding) | Grinding head 4# (fine grinding) | Grinding head 5# (fine grinding) | Grinding head 6# (fine grinding) | Grinding head 7# (fine grinding) | Grinding head 8# (polishing) | Grinding head 9# (polishing) | |

| Motor | Power (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 1.5/4 pole | 1.5/4 pole |

| Speed (rpm, 2 poles) | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 1400 | 1400 | |

| Grinding wheel | Specification (mm) | Φ150×22, 100 mesh | Φ150×22, 240 mesh | Φ150×22, 180 mesh | Φ150×22 | Φ150×22 | Φ150×22 | Φ150 | Φ150 | Φ150 |

| Name | Diamond wheel | Diamond wheel | PE wheel | Resin wheel | Resin wheel | Resin wheel | 10S40 polishing wheel | Felt wheel polishing wheel | Felt wheel polishing wheel | |

| Production place | Foshan, China | Foshan, China | Foshan, China | Suzhou, China | Suzhou, China | Suzhou, China | Germany | Germany | Germany | |

Grinding Wheel Layout and Technical Parameters for RBL361B

| Item | Grinding head 1# (rough grinding) | Grinding head 2# (rough grinding) | Grinding head 3# (rough grinding) | Grinding head 4# (fine grinding) | Grinding head 5# (fine grinding) | Grinding head 6# (fine grinding) | Grinding head 7# (fine grinding) | Grinding head 8# (polishing) | Grinding head 9# (polishing) | Grinding head 10# (polishing) | |

| Motor | Power (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 1.5 | 1.5/4 pole |

| Speed (rpm, 2 poles) | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 1400 | 1400 | |

| Grinding wheel | Specification (mm) | Φ150×22, 100 mesh | Φ150×22, 240 mesh | Φ150×22, 180 mesh | Φ150×22 | Φ150×22 | Φ150×22 | Φ150×22 | Φ150 | Φ150 | Φ150 |

| Name | Diamond wheel | Diamond wheel | Diamond wheel | PE wheel | Resin wheel | Resin wheel | Resin wheel | 10S40 polishing wheel | Felt wheel polishing wheel | Felt wheel polishing wheel | |

| Production place | Foshan, China | Foshan, China | Foshan, China | Foshan, China | Suzhou, China | Suzhou, China | Suzhou, China | Germany | Germany | Germany | |

Grinding Wheel Layout and Technical Parameters for RBL371B

| Item | Grinding head 1# (rough grinding) | Grinding head 2# (rough grinding) | Grinding head 3# (rough grinding) | Grinding head 4# (fine grinding) | Grinding head 5# (fine grinding) | Grinding head 6# (fine grinding) | Grinding head 7# (fine grinding) | Grinding head 8# (polishing) | Grinding head 9# (polishing) | Grinding head 10# (polishing) | Grinding head 11# (polishing) | |

| Motor | Power (kW) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 1.5 | 1.5 | 1.5/4 pole |

| Speed (rpm, 2 poles) | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 2800 | 1400 | 1400 | 1400 | |

| Grinding wheel | Specification (mm) | Φ150×22, 100 mesh | Φ150×22, 240 mesh | Φ150×22, 180 mesh | Φ150×22 | Φ150×22 | Φ150×22 | Φ150×22 | Φ150 | Φ150 | Φ150 | Φ150 |

| Name | Diamond wheel | Diamond wheel | Diamond wheel | PE wheel | Resin wheel | Resin wheel | Resin wheel | 10S40 polishing wheel | Felt wheel polishing wheel | Felt wheel polishing wheel | Felt wheel polishing wheel | |

| Production place | Foshan, China | Foshan, China | Foshan, China | Foshan, China | Suzhou, China | Suzhou, China | Suzhou, China | Germany | Germany | Germany | Germany | |

Related Names

Glass Bevel Machine | Glass Fabrication Equipment | Glass Cutting Tool

Links:https://globefindpro.com/products/82497.html

-

RTJ2325E/2330E Table Saw

RTJ2325E/2330E Table Saw

-

RMZ73213 3 Lines Boring Machine

RMZ73213 3 Lines Boring Machine

-

RBL0222 Glass Drilling Machine

RBL0222 Glass Drilling Machine

-

RBL1-6 Irregular Glass Edging Machine

RBL1-6 Irregular Glass Edging Machine

-

RBM412D/516E/623A Four Sided Planer Moulder

RBM412D/516E/623A Four Sided Planer Moulder

-

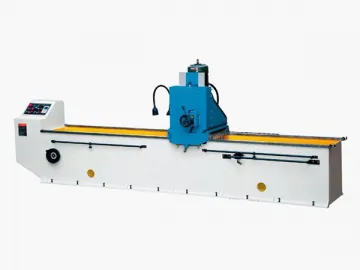

RMD2530 Linear Grinder

RMD2530 Linear Grinder

-

RXC230M Dust Extractor

RXC230M Dust Extractor

-

RMD2510C/2515C Linear Grinder

RMD2510C/2515C Linear Grinder

-

RFM2300C Vacuum Membrane Press

RFM2300C Vacuum Membrane Press

-

RBF300B-II Profile Wrapping Machine

RBF300B-II Profile Wrapping Machine

-

RQS3112/3125 Pneumatic Drum Sander

RQS3112/3125 Pneumatic Drum Sander

-

RMJ143E/143F/145E/145F Multi-Blade Rip Saw

RMJ143E/143F/145E/145F Multi-Blade Rip Saw