PVC Profile Extrusion Line

| PVC profile forming machine | Feeding machine | Plastic drawing and cutting machine |

| Plastic drawing and cutting machine 2 | PVC decoration panel forming machine | Plastic forming machine |

| Plastic extruder | PVC profile extrusion line |

PVC Profile Samples

| PVC window profile | Batten | PVC window profile |

| Microcellular plastic doorframe | Microcellular plastic doorframe | PVC window profile |

| PVC window profile | PVC window profile |

The perfect coordination among components of a plastic profile extrusion line is the guarantee for quality end products. YIM offers a great variety of extrusion machine and auxiliary equipment options for customers to choose from. Also available is customized extrusion solutions designed as per clients’ specific demands.

According to the desired end product type and the raw material properties, we design our PVC profile extrusion line with optimized screw, so as to provide the production line with features such as high productivity, stable performance, wide application range, long service life, uniform material plasticizing and mixing, as well as convenient PVC profile forming. Working with corresponding dies and auxiliary machines, the PVC profile extruder can be used for producing various dado rails, ceiling panels, plastic door and window profiles, and more.

Screw and Barrel

The extruder screw and barrel are made of superior quality 38CrMoAIA, and undergo nitrogen treatment to enhance resistance to wearing, corrosion, and high temperature. Also, the barrel discharging segment and screw surface are sprayed with Ni60 coating to improve abrasion resistance.

Electrical Component

To ensure performance stability and low energy consumption, our PVC profile extrusion line is fitted with electrical components from world-renowned suppliers, including Schneider air switches, RKC temperature control meters, Siemens contactors and electrical motors, FUJI or ABB variable frequency drives, etc. All these electrical components are available with International Warranty Service. This enables worldwide customers to attain professional maintenance and technical support services as well as convenient component replacement.

Auxiliary Machines

The plastic vacuum forming machine for the PVC profile extrusion line is airtight and it offers reliable cooling performance. It ensures convenient process observation.

The plastic drawing and cutting machine is characterized by low noise, adjustable drawing speed, fast cutting speed, and smooth incision.

Choose Us, You Will Attain

Improved production efficiency and enhanced performance reliability

High flexibility due to multiple options of production line design

Exceptional price-performance ratio

Applications and Our Services

This range of plastic extrusion machinery is applicable for standardized production of various PVC profiles, including door and window profiles, and other building profiles. Tailor-made PVC profile production line is available to satisfy clients’ individual demands as well. Additionally, we can offer solutions to help customers build a new production line or upgrade existing production lines.

Technical Specifications

| Model | YF180 | YF240 | YF300 |

| Max. vacuum degree (Mpa) | 0.08-0.098 | 0.08-0.098 | 0.08-0.098 |

| Vacuum forming machine length (mm) | 3000 | 6000 | 6000 |

| Die mounting height (mm) | 820 | 820 | 820 |

| Moving distance of vacuum forming machine (mm) | 500 | 500 | 500 |

| Plastic drawing speed (m/min) | 0.6-6 | 0.4-6 | 0.4-6 |

| Drawing force (kn) | 30 | 44 | 55 |

| Effective drawing length (mm) | 1800 | 2400 | 2400 |

| Cutting speed (m/s) | 58.6 | 58.6 | 58.6 |

| Max. cutting surface area (mm) | 180*100 | 240*85 | 300*85 |

window.onload =function() {setItemByDivId('container','one|two|three|four|five|six','etw_link','color:#fff; background:#1679BA;','color:#333;background:#ccc','setclass');}

Links:https://globefindpro.com/products/82632.html

-

WPC Extrusion Line

WPC Extrusion Line

-

TA52 Particle / Masterbatch for Profile Extrusion

TA52 Particle / Masterbatch for Profile Extrusion

-

Other Extruder Parts

Other Extruder Parts

-

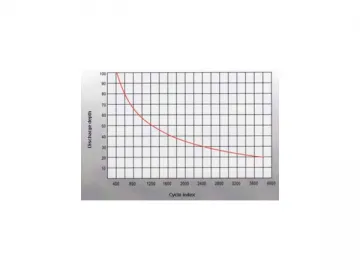

Flat Plate Gel Golf Cart Battery

Flat Plate Gel Golf Cart Battery

-

Plastic Conveyor and Cutting Machine

Plastic Conveyor and Cutting Machine

-

Single Screw Extruder

Single Screw Extruder

-

PP Fiber Masterbatch

PP Fiber Masterbatch

-

Plastic Vacuum Forming Machine

Plastic Vacuum Forming Machine

-

Injection Molding Masterbatch

Injection Molding Masterbatch

-

Lawn Mower Battery

Lawn Mower Battery

-

Non Woven Fabric Masterbatch

Non Woven Fabric Masterbatch

-

CA22 Particle / Masterbatch for Pipe Extrusion

CA22 Particle / Masterbatch for Pipe Extrusion