WPC Extrusion Line

| Extruder | WPC profile extrusion line | WPC profile forming machine |

| WPC forming machine | Drawing and cutting machine | WPC door panel forming machine |

| WPC extrusion line | ||

Extruded WPC Products

| Extruded WPC product | WPC panel | WPC panel |

| WPC panel | WPC panel | WPC door |

| WPC door and doorframe | WPC doorframe | WPC doorframe |

| WPC doorframe | WPC doorframe | Skirting board |

| WPC profile | WPC profile | WPC profile |

| WPC profile |

Wood plastic composites, WPC, are a widely used building material, especially for decking, due to their superior attributes, like natural look, high stiffness, moisture resistance, good processability, low price, etc. We offer premium WPC extrusion line for producing a great number of WPC products, such as WPC profile, chair rail, ceiling panel, decorative wall panel, and more.

Based on the properties of wood plastic composites, we design our WPC extrusion line with optimized screw structure, so as to obtain high productivity, long lifespan, wide application range, stable performance, as well as uniform material plasticizing and mixing.

The extruder screw and barrel offer remarkable resistance to wearing, corrosion, and high temperature, due to the quality 38CrMoAIA raw material and nitrogen treatment. The Ni60 coating for the discharging end of barrels and the thread surface of screws also improves durability.

The vacuum forming machine, an important part of the WPC extrusion line, offers reliable cooling and good air tightness. It is designed to allow operators to observe the forming process conveniently. Another core part for the WPC production line is our drawing and cutting machine. It has features such as low noise, adjustable drawing speed, fast cutting speed, and smooth incision.

Our WPC extrusion line is equipped with famous brand electrical components to guarantee high stability, low failure rate, and low energy consumption. These components include Schneider air switch, RKC temperature control meter, FUJI or ABB variable frequency inverter, Siemens contactor and electric motor, to name a few. Available with International Warranty Service, they enjoy worldwide convenient replacement and maintenance service, and enable users to get professional technical support anywhere anytime.

Our Advantages

1. Our WPC extrusion line is available with the screw diameter of 38mm to 188mm and offers a production capacity between 20kg/h and 800kg/h. It is a custom made production line for wood-plastic composite products.

2. Vast experience in this industry allows us to have a data base for WPC extruder screws.

3. We offer weighing and feeding solutions compatible with various types of raw materials.

4. We equip our WPC board making machine with quality and efficient electrical components.

Choose Us, You Will Attain

A production line supporting direct end product extrusion and WPC granules extrusion

Highly efficient machines capable of long term continuous operation

Professional technical support based on our years of experience

Technical Specifications

| Model | YF180 | YF240 | YF300 |

| Max. vacuum degree (MPA) | 0.08-0.098 | 0.08-0.098 | 0.08-0.098 |

| Vacuum forming machine length (mm) | 3000 | 6000 | 6000 |

| Extrusion die mounting height (mm) | 820 | 820 | 820 |

| Moving distance of vacuum forming machine (mm) | 500 | 500 | 500 |

| Drawing speed (m/min) | 0.6-6 | 0.4-6 | 0.4-6 |

| Drawing force (kn) | 30 | 44 | 55 |

| Effective drawing length (mm) | 1800 | 2400 | 2400 |

| Cutting speed (m/s) | 58.6 | 58.6 | 58.6 |

| Max. cutting surface area (mm) | 180*100 | 240*85 | 300*85 |

window.onload =function() {setItemByDivId('container','one|two|three|four|five|six','etw_link','color:#fff; background:#1679BA;','color:#333;background:#ccc','setclass');}

Links:https://globefindpro.com/products/82633.html

-

TA52 Particle / Masterbatch for Profile Extrusion

TA52 Particle / Masterbatch for Profile Extrusion

-

Other Extruder Parts

Other Extruder Parts

-

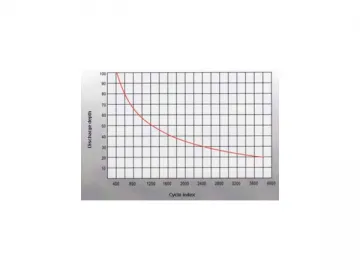

Flat Plate Gel Golf Cart Battery

Flat Plate Gel Golf Cart Battery

-

Plastic Conveyor and Cutting Machine

Plastic Conveyor and Cutting Machine

-

Single Screw Extruder

Single Screw Extruder

-

Plastic Crusher

Plastic Crusher

-

PVC Profile Extrusion Line

PVC Profile Extrusion Line

-

PP Fiber Masterbatch

PP Fiber Masterbatch

-

Plastic Vacuum Forming Machine

Plastic Vacuum Forming Machine

-

Injection Molding Masterbatch

Injection Molding Masterbatch

-

Lawn Mower Battery

Lawn Mower Battery

-

Non Woven Fabric Masterbatch

Non Woven Fabric Masterbatch