Plastic Crusher

| SWP400 model | SWP500 model | SWP600 model |

| SWP1200 model |

For plastic recycling, the first step is to crush the plastic products to be reclaimed down to a manageable or reusable size, no matter whether it is a PVC pipe, plastic bottle, or other plastic articles of various sizes. Our plastic crusher is the perfect machine for completing size reduction tasks.

Superior quality tool steel and specially-made cutting tool ensure durability. The plastic crusher adopts extension-type cutting tool installation method. Thus, the blunt blades can be sharpened for many times for repeated use, extending service life. The moving knife stand in step-style design effectively decomposes the stress, resulting in increased cutting force. Made of top grade tool steel T7A with proper toughness, the knife stand ensures neither fracture nor wearing. High strength steel fastening bolt of Grade 8.8 ensures secure fastening and solid structure.

The main body part of the plastic crusher is made of thick Q235A structural steel, which avoids performance degradation due to long term operation. The machine axis and both ends are processed by high precision jig borers, so as to make sure the error of concentricity and perpendicularity is no more than 0.05mm. Each of the machine parts undergoes both rough and precision processing, which contributes to high size accuracy and interchangeability.

Crushing chamber

The crushing chamber of the plastic crusher is assembled using high hardness, 30mm thick sheet steel after machining and precision polishing. It is pollution-free, and features high strength, good wearing resistance, and long service life. The assembled structure makes the chamber convenient for disassembly and mounting as well.

Cutting tool

The moving knife adopts V-style cutting technology to provide low operational noise, reduced energy consumption, and uniform particle size. It features simple mounting and dismounting, and is also convenient for maintenance. Made of H13K material, the cutting knife has high strength and high toughness, and won’t break easily.

Spindle

The spindle made from 40Cr undergoes both dynamic and static balance tests. With high toughness, it offers superior stability and resistance to deformation during operation.

Belt pulley

Our plastic crusher adopts shaft couplers to connect the drive shaft and the belt pulley. The connection allows the belt pulley to match perfectly with other parts, and ensures balanced operation, convenient maintenance, as well as easy mounting and dismounting.

Screen cloth

The high strength steel material provides the screen plate with high strength and great durability. The screen plate can be conveniently mounted to the plastic crushing machine, in either electric or manual mode. It can be simply exchanged as well. Screen cloth with varied mesh size options is also available.

Primary Technical Specifications

| Model | SWP400 | SWP500 | SWP560 | SWP630 | SWP1200 |

| Moving knife swing diameter (mm) | 400 | 470 | 520 | 590 | 680 |

| Moving knife quantity | 5 | 5 | 5 | 5 | 30 |

| Moving knife speed (r/min) | 520 | 520 | 550 | 550 | 630 |

| Fixed knife quantity | 2 | 2 | 2 | 2 | 2 |

| Screen mesh (mm) φ | 8-12 | 10-14 | 10-14 | 10-14 | 10-14 |

| Crushing capacity (kg/h) | 250-400 | 350-500 | 400-600 | 600-800 | 1200-2000 |

| Motor power (kW) | 15 | 22 | 30 | 37 | 132 |

| Fan power (kW) | 3 | 3 | 4 | 4 | 7.5 |

| Feeding port size (mm) | 330X350 | 400X450 | 480X550 | 520X550 | 660X1250 |

| Machine weight (kg) | 1200 | 1400 | 1800 | 2500 | 5000 |

Links:https://globefindpro.com/products/82640.html

-

Plastic Mixer

Plastic Mixer

-

CA30 Particle / Masterbatch for Sheet Extrusion

CA30 Particle / Masterbatch for Sheet Extrusion

-

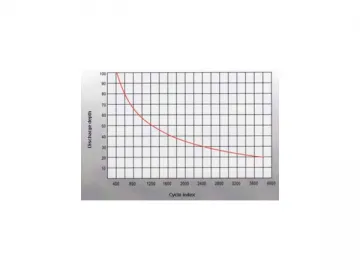

Gel Motorcycle Battery

Gel Motorcycle Battery

-

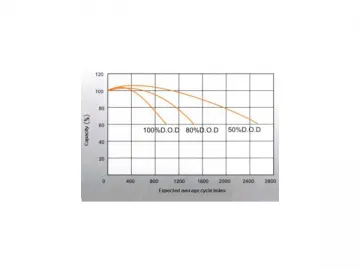

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

High Performance Dry-Charged Motorcycle Battery

High Performance Dry-Charged Motorcycle Battery

-

Single Screw Extruder

Single Screw Extruder

-

Plastic Conveyor and Cutting Machine

Plastic Conveyor and Cutting Machine

-

Flat Plate Gel Golf Cart Battery

Flat Plate Gel Golf Cart Battery

-

Other Extruder Parts

Other Extruder Parts

-

TA52 Particle / Masterbatch for Profile Extrusion

TA52 Particle / Masterbatch for Profile Extrusion

-

WPC Extrusion Line

WPC Extrusion Line