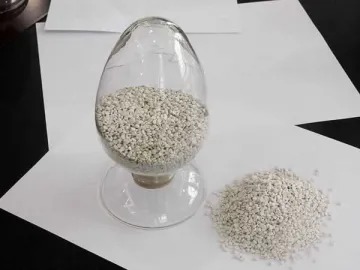

CA30 Particle / Masterbatch for Sheet Extrusion

The CA30 masterbatch, using polypropylene as the main carrier material, is widely used to modify properties of polyethylene extrusion products.

According to the market situation, our company has developed master batch for top grade lunch boxes, loose-leaf folders, and other extruded sheet products. The material has good dispersibility, high adding proportion, and other advantages.

Features

1. Using the CA30 masterbatch for sheet extrusion can reduce cost and there is no dust spill during manufacturing.

2. This material can improve the rigidity, stiffness, and heat resistance of the finished product, and reduce product defect rate.

3. It has good plasticization and dispersion properties.

| Model | Melt index | Whiteness | Density | Mineral fineness | Recommended adding proportion | Scope of application |

| CA30 | 1.0-5.0 | ≥ 90 | 1.67-1.73 | 2000 | 10-50% | PP/PE sheet such as PP cutlery, binder, plastic curtain, plastic pipe and sheet, placemat sheet, etc. |

FM is a professional particle / masterbatch for sheet extrusion manufacturer and supplier in China. We offer a vast range of products, including calcium carbonate filler masterbatch, particle / masterbatch for pipe extrusion, injection molding masterbatch, and more.

Related Names

Additive Masterbatch for PP Material | Extrusion Aid Manufacturer | Filler Master Batch for Hollow Sheet

Links:https://globefindpro.com/products/82642.html

-

Gel Motorcycle Battery

Gel Motorcycle Battery

-

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

High Performance Dry-Charged Motorcycle Battery

High Performance Dry-Charged Motorcycle Battery

-

Talc Filler Masterbatch

Talc Filler Masterbatch

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

Plastic Mixer

Plastic Mixer

-

Plastic Crusher

Plastic Crusher

-

Single Screw Extruder

Single Screw Extruder

-

Plastic Conveyor and Cutting Machine

Plastic Conveyor and Cutting Machine

-

Flat Plate Gel Golf Cart Battery

Flat Plate Gel Golf Cart Battery

-

Other Extruder Parts

Other Extruder Parts