Conical Twin Screw Extruder

| PLC extruder | Plastic extruder /co-extruder (92-188 series) | Plastic extruder (92-188 series) |

| Plastic extruder (80 series) | Plastic extruder (80-172 series) | Plastic extruder (80-156 series) |

| Front panel of 65 plastic extruder (65 series) | Backside of extruder(65-132 series) | Plastic profile extruder(65-132 series) |

| 65 plastic extruder (65 series) | 65 plastic extruder (65 series) |

The conical twin screw extruder can be used for the extrusion of PVC pipes, profiles, sheets, plates, bars, and granules when applied in combination with corresponding die and auxiliary equipment. Due to the optimal screw design made according to the desired type of extrusion part as well as the raw material characteristics, this plastic extrusion equipment boasts high output, stable performance, long service life, and homogeneous plasticizing.

Features

1. The screw cooling system adopts inter-circulation oil cooling or external-circulation air cooling.

2. Nitrogen treatment for the screw and barrel made from 38CrMoAIA, as well as the Ni60 coating for the screw surface and barrel discharging end, guarantees high durability due to improved resistance to wearing, corrosion, and high temperatures.

3. Our conical twin screw extruder is energy efficient with stable performance and low failure rate, thanks to the premium electrical components adopted, such as the Schneider air switch, RKC temperature control meter, Siemens contactor and electric motor, as well as FUJI or ABB variable frequency motor. These components with International Warranty Service allow worldwide users to enjoy easily accessible maintenance, replacement, and technical support services.

Advantages Bought to You

1. Proven quality conical twin screw extruder with high price-performance ratio

2. High flexibility due to gentle, homogeneous plasticizing

3. Multiple screw geometric design options for processing customer-specific PVC compounds

4. Maintenance-free screw cooling system

5. AC motors with low energy consumption

What We Offer

1. Multiple choices for screw diameter

2. PVC profile outputs from 90 kg/h to 800 kg/h

3. PVC pipe outputs from 150 kg/h to 1200 kg/h

4. State-of-the-art technologies and stable running

Main Technical Specifications

| Model / Specifications | SJSZ45/90 | SJSZ50/103 | SJSZ55/110 | SJSZ60/125 | SJSZ65/132 | SJSZ80/156 | SJSZ80/172 | SJSZ92/188 |

| Diameter of screws (mm) | 45/90 | 50/103 | 55/110 | 60/125 | 65/132 | 80/156 | 80/172 | 92/188 |

| Quantity of screws | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Rotation direction of screws | Outwards rotation in different directions | |||||||

| Speed of screws (r/min) | 1-37 | 1-35 | 1-35 | 1-35 | 1-35 | 1-37 | 1-37 | 1-32 |

| Effective length of screws (mm) | 985 | 1035 | 1195 | 1314 | 1440 | 1800 | 1830 | 2540 |

| Main motor power (kw) | 15 | 22 | 27 | 30 | 37 | 55 | 90 | 110 |

| Barrel heating power(kw) | 12 | 11.5 | 18 | 21 | 24 | 36 | 43.8 | 78 |

| Production capacity (kg/h) | 95 | 90-150 | 150 | 120-200 | 250 | 450 | 350~650 | 800 |

| Equipment center height (mm) | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1200 |

| Weight (kg) | 3000 | 3000 | 3500 | 4000 | 4500 | 5500 | 5000 | 6500 |

| Dimension (L*W*H) (mm) | 3.35×1.3×2.1 | 3.38×1.3×1.6 | 3.6×1.5×2.2 | 4.2×1.5×2.4 | 4.5×1.5×2.4 | 4.8×1.6×2.5 | 5.0×1.6×2.6 | 4.7×2.0×2.3 |

Links:https://globefindpro.com/products/82649.html

-

PVC/PE/PP Pipe Extrusion Line

PVC/PE/PP Pipe Extrusion Line

-

Casting Film Masterbatch

Casting Film Masterbatch

-

PE/PP Recycling Line

PE/PP Recycling Line

-

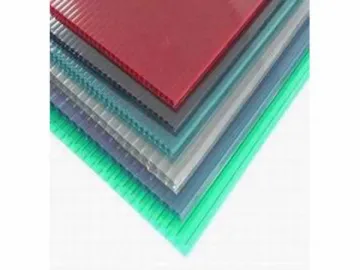

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

-

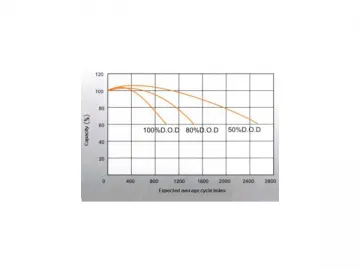

VRLA Battery (Valve-regulated Lead-acid Battery)

VRLA Battery (Valve-regulated Lead-acid Battery)

-

Calcium Carbonate Filler Masterbatch

Calcium Carbonate Filler Masterbatch

-

Talc Filler Masterbatch

Talc Filler Masterbatch

-

High Performance Dry-Charged Motorcycle Battery

High Performance Dry-Charged Motorcycle Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

Gel Motorcycle Battery

Gel Motorcycle Battery

-

CA30 Particle / Masterbatch for Sheet Extrusion

CA30 Particle / Masterbatch for Sheet Extrusion