PVC/PE/PP Pipe Extrusion Line

| Plastic pipe extrusion line | Plastic pipe extrusion line | SJ65-33 Single screw extruder |

| SJ65-33 Single screw extruder | Plastic pipe extrusion line | PE pipe extrusion line |

Extruded Pipe Samples

| PE-PP Pipe | PE Double-wall Corrugated Pipe | PVC Pipe |

| Corrugated Pipe |

Our pipe extrusion line can be used to produce PVC, HDPE, and HDPP pipes with the diameter between 12mm and 400mm. The well-coordinated components, coupled with auxiliary machines, allow this pipe production line to produce pipes for different purposes, including drain pipes, water supply pipes, electrical conduits, PVC fire-retardant pipes, as well as piping for use in chemical industry.

Design Advantages

1. Our PVC, PE, and PP pipe extrusion lines are designed with optimized screw structure, according to desired pipe specifications and raw material properties. This ensures high output, stable performance, wide application range, long service life, as well as uniform plasticizing and mixing.

2. The extruder screw and barrel made from 38CrMoAIA undergo nitrogen treatment. The discharge end of barrel and the thread surface of screw come with Ni60 coating. These ensure high durability of our plastic extruders.

3. Famous brand electrical components are adopted to ensure low failure rate and high performance stability. To illustrate, the PVC, PE or PP pipe extrusion line is equipped with RKC temperature control meter, FUJI or ABB variable frequency drive, as well as Siemens contactor and electrical motor. With International Warranty Service, these components can be conveniently replaced. Professional maintenance service and technical support are available as well.

4. The vacuum forming machine, one of the components of the pipe extrusion line, makes process observation convenient and it has good air tightness.

5. The plastic drawing and cutting machine boasts stable and adjustable drawing speed as well as advantages like fast cutting, smooth incision, low noise, etc.

6. We can also offer downstream equipment for aiding PVC, PE and PP pipe production. Clients can choose a suitable type of equipment according to their specific demands. Available equipment includes the sizing sleeve, spray cooling tank, single- and double-chamber vacuum sizing tanks, as well as belt type and crawler type drawing machines. These machines are energy-saving, and help deliver fine quality end products, due to our equal emphasize on them.

Why Choose Us

1. We can offer manufacturing lines to make PO pipes with diameter from 16mm to 1,200mm.

2. We supply professional technical support, custom production line as per clients’ individual demands, as well as optimized solutions to assist customers in new production line assembly and existing production line upgrading.

3. Offering turnkey projects to satisfy customers’ plastic pipe extrusion demands is our core competitiveness. By offering advanced equipment and intelligent automation system, we can meet each of our customers’ requirements.

Choose Us, You Will Attain

A turnkey solution for plastic pipe production

An extruded plastic pipe extrusion line with maximized production efficiency and reliability

High flexibility in extrusion line configuration and design

Verified high quality and high price-performance ratio

Technical Parameters

| Auxiliary Machine Model | Vacuum sizing diameter(mm) | Sizing length (mm) | Effective drawing length(mm) | Drawing Speed(m/min) | Drawing force (kn) | Cutter type | Cooling water consumption (m3/h) | Air consumption/h) | Total power (kw) |

| 160 | 12-160 | 6000 | 1400 | 0.6-6 1.6-16 | 30 | Circular saw | 3 | 2 | 22 |

| 250 | 110-250 | 6600 | 2000 | 0.37-3.7/ 0.75-7.5 | 30 | Annular cutter | 5 | 3 | 20 |

| 400 | 220-400 | 6600 | 2380 | 0.11-1.1/ 0.2-2.0 | 30 | Annular cutter | 9 | 4 | 27 |

window.onload =function() {setItemByDivId('container','one|two|three|four|five|six','etw_link','color:#fff; background:#1679BA;','color:#333;background:#ccc','setclass');}

Links:https://globefindpro.com/products/82650.html

-

Casting Film Masterbatch

Casting Film Masterbatch

-

PE/PP Recycling Line

PE/PP Recycling Line

-

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

PE81 Particle / Masterbatch for Hollow Sheet Extrusion

-

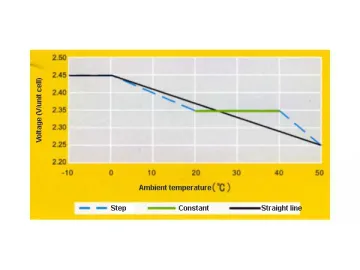

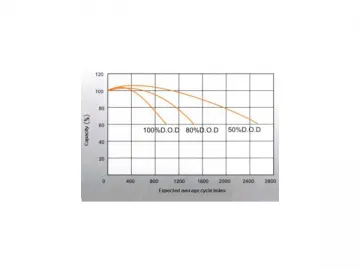

VRLA Battery (Valve-regulated Lead-acid Battery)

VRLA Battery (Valve-regulated Lead-acid Battery)

-

Calcium Carbonate Filler Masterbatch

Calcium Carbonate Filler Masterbatch

-

PzV Tubular Gel Battery

PzV Tubular Gel Battery

-

Conical Twin Screw Extruder

Conical Twin Screw Extruder

-

Talc Filler Masterbatch

Talc Filler Masterbatch

-

High Performance Dry-Charged Motorcycle Battery

High Performance Dry-Charged Motorcycle Battery

-

PVC/PE/PP Granulation Line

PVC/PE/PP Granulation Line

-

Tubular Plate Gel Golf Cart Battery

Tubular Plate Gel Golf Cart Battery

-

Gel Motorcycle Battery

Gel Motorcycle Battery