FH100 Sanitary Mix Proof Valve

The FH100 stainless steel sanitary mix proof valve is used to separate media which can not be mixed in the junction of flow channels. In the closed area, both of the pipelines are sealed to prevent the liquid from leaking to another pipeline. If the seal is damaged, the liquid leaked will flow outside through the drainage chamber. Lotion can flow into the separation chamber through a pipe connected to an independent CIP. The cleaning of separation chamber will not be influenced by the valve’s location.

Technical Parameters

1. Material pressure range: 0~8bar

2. Temperature range: -10℃~ 150℃

3. Operative air pressure: 6~8bar

Materials

1. Contact surface between the product and medium: 304 or 316L

2. Seal: Standard: EPDM

Optional: Silica gel or fluorine gel

Surface Finish of FH100 Sanitary Mix Proof Valve

1. Outside: Sandblasting: Ra≤1.6 mm

Matt Polishing: Ra≤0.6 mm

2. Inside: Polishing: Ra≤0.6 mm

Requirements for Compressed Air Quality The Actuator Needs

1. Compressed air connection: Air tube equipped with air hose coupling R1/8"

2. Maximum particle size: 0.01mm

3. Maximum oil content: 0.08ppm

4. Dew point: ≤-10℃

5. Maximum water content: 7.5g/kg

Related Names

Product Contamination Prevention Device | Drink Manufacturing Equipment Accessories | Flow Diverting Fittings

Links:https://globefindpro.com/products/82721.html

-

Standard Dry-Charged Motorcycle Battery

Standard Dry-Charged Motorcycle Battery

-

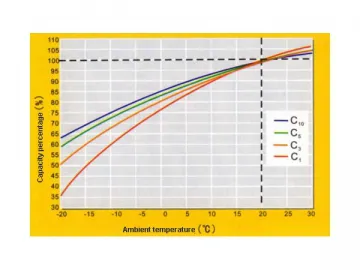

OPzV Tubular Gel Battery

OPzV Tubular Gel Battery

-

Sanitary Pressure Reducing Valve / Pressure Regulator

Sanitary Pressure Reducing Valve / Pressure Regulator

-

Flat Plate Flooded Golf Cart Battery

Flat Plate Flooded Golf Cart Battery

-

Spring Brake Chamber

Spring Brake Chamber

-

Manual Slack Adjuster

Manual Slack Adjuster

-

Flanged Compressed Air Filter (27~210m³/min)

Flanged Compressed Air Filter (27~210m³/min)

-

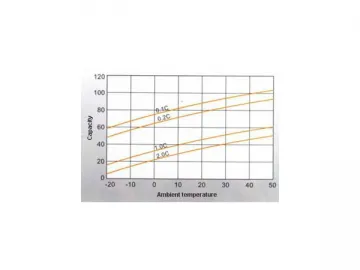

Air Spring

Air Spring

-

Brake Pad

Brake Pad

-

Electric Bike for Students

Electric Bike for Students

-

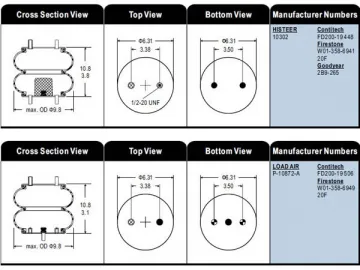

Color Coated Steel

Color Coated Steel

-

Electric Bike for the Youth

Electric Bike for the Youth