Oil Degumming Process

The oil degumming process is of great necessity. The soluble gum impurities in the crude oil will exert great impact on the oil stability, on oil refining process effects (such as emulsification occurring in alkali refining, increase in adsorbent dosage during decoloring, failure to deodorization, etc.) and on applications of oil products (such as foaming during heating).

Washing and Degumming System

In line with the hydrophilcity of soluble gum impurities in the vegetable oil, such as phospholipid, the water soluble gum will agglomerate, subside and separate from vegetable oil by addition of hot water in an appropriate amount and control of corresponding conditions.

After being dried up, the separated gum can be made into lecithin or be added to the cake meal in the extraction plant. The hydrated and degummed oil can be regarded as the commodity. It can be well stored and the edibility has been evidently improved, which is favorable for next neutralization as well as other procedures.

Continuous Degumming Equipment

Disk centrifuge is used for separation of oil from gum continuously in the degumming process. The filtered crude oil containing 0.2% impurities is heated up to 80℃ to 85℃, after being measured. Then, it fully mixes with the 90℃ hot water in the mixing device. The mixture is delivered to the reactor for 40 minute reaction. Afterwards, it is pumped into the disk centrifuge for separation of oil from gum.

The water content of the degummed oil ranges from 0.2 % to 0.5%. The degummed oil is heated to around 95℃ by the heating device and then dried up by the vacuum dryer whose vacuum degree is from 680 to 700mmHg. After that, it will be cooled to 40℃ by the cooling unit and then transported to the degummed oil storage tank.

Intermittent Degumming Equipment

The degumming pot is employed for intermittent oil hydration and degumming. The degumming process can be illustrated as follows.

1. Soft Water for Hydration ①

2. Filtered Crude Oil→ Pre-heating→ Hydration ①→ Standing Statically for Sedimentation → Separation ②→ Containing Water→ Degummed Oil→ Drying (Solvent Removal) → Degummed Oil

3. Separation ② → Oil Stock of Fat Oil → Treatment of Oil Stock→ Oil Recovery

As a China-based oil degumming equipment manufacturer and supplier, we also provide PTO pellet mill, magnetic separation machine, oil seed flaking machine, laboratory roller mill, and much more.

Related Names

Oil Processing System | Degumming of Vegetable Oil

Links:https://globefindpro.com/products/82852.html

-

Hammer Mill

Hammer Mill

-

Solvent Recovery Machine

Solvent Recovery Machine

-

Counter-Flow Cooling Machine

Counter-Flow Cooling Machine

-

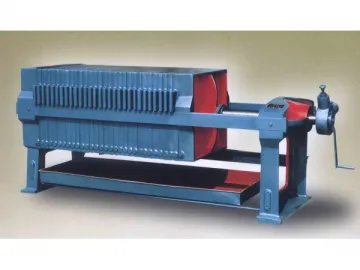

Filter Press, Leaf Filter

Filter Press, Leaf Filter

-

ZLSP-A R-Type Diesel Pellet Mill

ZLSP-A R-Type Diesel Pellet Mill

-

Chaff Cutter

Chaff Cutter

-

ZLSP-R PTO Pellet Mill

ZLSP-R PTO Pellet Mill

-

Small Complete Set of Pellet Equipment

Small Complete Set of Pellet Equipment

-

Oil Deodorization System

Oil Deodorization System

-

Air Aspirator and Air Suction Channel

Air Aspirator and Air Suction Channel

-

ZSLP-A D-Type Diesel Pellet Mill

ZSLP-A D-Type Diesel Pellet Mill

-

Metal Dog Cage

Metal Dog Cage