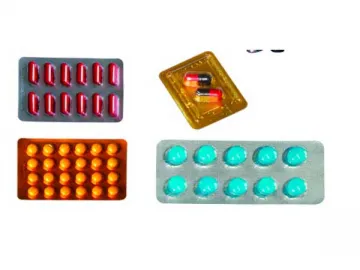

DCT-250P Blister Packing and Cartoning Line

DCT-250P Blister Packing and Cartoning Line is suitable for blister packing and cartoning of injections, oral liquids, disposable syringes and ampoules. Every part of the line adopts advanced independent PLC human machine interface, which leads to easy operation. Alarm system guarantees the normal operation of the production line. Servo mechanical in-feed system is applied to ensure accuracy of charging. Advanced testing methods used in every operation step, along with the safe and reliable on-line testing system, contribute to high quality and acceptability of finished products.

Technical Parameters

| MAX. Production Capacity | <100 boxes/min. | |

| MAX. Formed Area and Depth | 245*130*30mm | |

| Carton | Quality Requirement | 250-350g/m² |

| Size Range | 65-200*25-85*15-60mm | |

| Leaflet | Quality Requirement | 50-70g/m² |

| Size Range | 100-200mm*100-150mm | |

| Compressed air | Working pressure | 0.6-0.8MPa |

| Total Air consumption | >0.8m³/min. | |

| Machine Weight | 3500Kg | |

| Power Supply& Overall Power | 380V, 50Hz(220V, 60Hz); 8kW | |

Features

Configuration-Designed in compliant with GMP and CGMP standards and ergonomics principle, the machine also adopts an advanced servo intelligent drive and a PLC human machine interface. All parts, which come into direct contact medicine packed, are made of SUS316 stainless steel, which features high corrosion resistance. The main motor is controlled by a frequency inverter.

Moulds-Moulds and guide rails are designed separately. If users need to change the moulds, they just have to change the whole guide rail. Moulds are installed with pressure plates. Therefore, it is very easy to install and dismantle these moulds.

Stations-Each station can be controlled by computerized digital control system due to modular design of the station structure. An indentation station is added on the blister packing machine to meet diversified demands of indentation types. Meanwhile, clear indentations and batch numbers can be fully ensured.

Safety-When PVC runs out or breaks, the blister packing machine sends alarm signals and stops working. Emergency stop safety equipment is also available. Safety guard is also applied to ensure safety of operators. As a result, operators feel quite safe when they debug the machine or change moulds.

Optional

1. Advanced servo intelligent drive and photoelectric register are available. Cooling system is also offered if necessary.

2. To ensure safety of operators, customers can choose safety guard. Online visual test equipment can be provided to remove faulty finished products.

Sample

Related Names

Injection Blister Packaging Machine Supplier | Electronics Packaging | Equipment in Pharmaceutical Production

Links:https://globefindpro.com/products/84703.html

-

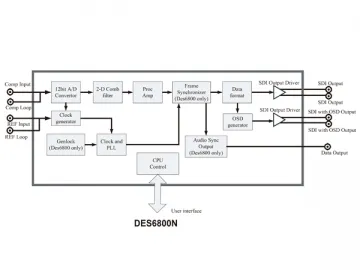

Audio/Video Test Signal Generator

Audio/Video Test Signal Generator

-

HM-1200B Grooving Machine

HM-1200B Grooving Machine

-

HM-DA660 Automatic Book Cover Maker

HM-DA660 Automatic Book Cover Maker

-

HM-420 Rigid Box Folding-in Machine

HM-420 Rigid Box Folding-in Machine

-

HM-S240 Automatic Box Corner Pasting Machine

HM-S240 Automatic Box Corner Pasting Machine

-

DPP-250G Blister Packing Machine

DPP-250G Blister Packing Machine

-

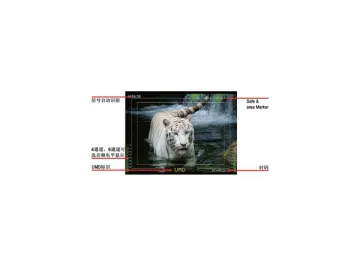

8 Inch Broadcast LCD Monitor

8 Inch Broadcast LCD Monitor

-

DPR-250 Blister Packing Machine

DPR-250 Blister Packing Machine

-

Video Converter

Video Converter

-

5.0 Inch Broadcast LCD Monitor

5.0 Inch Broadcast LCD Monitor

-

5.7 Inch Broadcast LCD Monitor

5.7 Inch Broadcast LCD Monitor

-

Intelligent Router (IRS)

Intelligent Router (IRS)