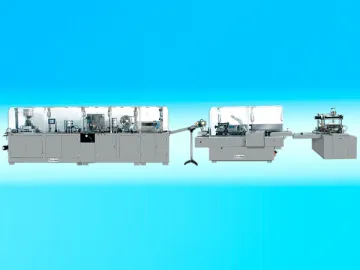

DPP-250G Blister Packing Machine

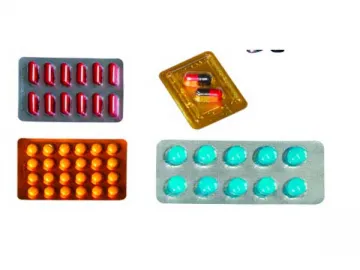

Users' feedback information helps to improve our design of DPP-250G blister packing machine, which is based on DPP-250E aluminum plastic blister packing machine. Advanced technology from abroad is adopted as well. Developed according to GMP standards, the machine is often applied for sealed packing of capsules, pills, injectors, candy, and hardware with blister aluminum plastic or paper plastic.

Main Technical Parameters

| PVC Width | 25mm |

| Max. Forming Area | 250*110mm |

| Cutting Frequency | 20-40 times/min. |

| Standard Blister Plate Size | 57*80mm(designed according to customers' requirements) |

| Adjustable Range of Stroke | 40-110mm(designed according to customers' requirements) |

| Main Motor Power | 1.5kW |

| Heating Power | 3.1kW |

| Rated Frequency | 50Hz |

| Rated Voltage | AC380V(three-phase four-wire) |

| Air Compressor | ≥ 0.15m3/min.(provided by customers) |

| Overall Dimension(L*W*H) | 2550*800*1360mm |

| Weight | 1200Kg |

Features

Adjustable Stroke-The blister plate size can be changed upon request. Hence, products in many sizes can be produced.

Plate Structure-The blister packing machine can be used to pack goods with various shapes, such as square, triangle, and oval.

Positive Pressure Forming-Pressure forming results in stiff and smooth bubble wall with uniform thickness as well as more beautiful finished product. Forming, feeding, heat sealing, impressing, printing batch numbers, punching and collecting waste material can be automatically performed at one time.

Waste Collector-The collector realizes automatic rewind recycle of waste material.

Sample

Related Names

Blister Packaging Equipment for Sale | Effective Packaging Solution | Packaging Plant

Links:https://globefindpro.com/products/84709.html

-

HM-YP300B Box Pressing Machine

HM-YP300B Box Pressing Machine

-

DCT-250 Blister Packing and Cartoning Line

DCT-250 Blister Packing and Cartoning Line

-

HM-1200C Automatic Grooving Machine

HM-1200C Automatic Grooving Machine

-

DXH-100 Automatic Cartoning Machine

DXH-100 Automatic Cartoning Machine

-

HM-22 White Glue Pasting Machine

HM-22 White Glue Pasting Machine

-

HM-600C Double Side Cover Edge Folding Machine

HM-600C Double Side Cover Edge Folding Machine

-

HM-S240 Automatic Box Corner Pasting Machine

HM-S240 Automatic Box Corner Pasting Machine

-

HM-420 Rigid Box Folding-in Machine

HM-420 Rigid Box Folding-in Machine

-

HM-DA660 Automatic Book Cover Maker

HM-DA660 Automatic Book Cover Maker

-

HM-1200B Grooving Machine

HM-1200B Grooving Machine

-

Audio/Video Test Signal Generator

Audio/Video Test Signal Generator

-

DCT-250P Blister Packing and Cartoning Line

DCT-250P Blister Packing and Cartoning Line