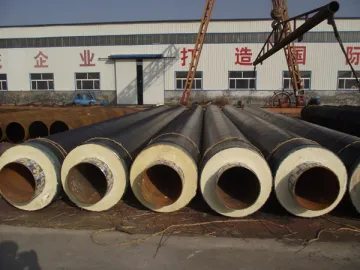

Steel Jacketed Insulated Pipe

The steel jacketed insulated pipe is a kind of buried steel pipe. It can be directly buried underground in case of no concrete structure, as the thermal expansion of the working steel tube is conducted inside of the outer steel tube. This helps reduce the material cost, shorten the construction time and guarantee the security of the heat supply pipeline.

By using a steel tube as the outer protective layer, our steel jacketed insulated pipe features high strength, easy maintenance, and long service life. Its ends are sealed by polyethylene film or three layers of PE tape, with the purpose of preventing entry of moisture or water before installation or during construction.

With the working temperature of up to 150℃ to 450℃, the insulated tubing can be extensively applied in diverse temperature environments, especially suitable for conveying steam and other medium with the pressure less than 2.5MPa and temperature below 350℃.

Based on the sliding mode, the thermal insulation structure of the steel jacketed insulated pipe can be divided into two categories.

1. Internal Sliding Type

The internal sliding type steel jacketed insulated pipe comprises a steel tube for conveying medium, composite silicate or microporous calcium silicate, rigid polyurethane foam, outer steel tube, and the glass reinforced plastic shell corrosion protective layer. Our insulation treatment technology for nodes of various tube fittings is mature, ensuring reliable quality.

2. External Sliding Type

The external sliding type steel jacketed insulated pipe consists of the working steel tube, glass wool insulation layer, aluminum foil reflective layer, stainless steel fastening steel strip, sliding guide bracket, air insulation layer, outer casing pipe, and external anticorrosion coating.

Links:https://globefindpro.com/products/84900.html