Pipe Reducer

As one of the chemical pipe fittings, the pipe reducer is for connecting two pipes of different diameters. There are concentric reducer and eccentric reducer. The generally used forming process is reducing pressing, expanding pressing or reducing plus expanding pressing. For the pipe reducer of certain specifications, stamping forming can also be employed.

Standard

| ASME B16.9-2007, ASME B16.25-2007, ASME B16.5-2007 |

| EN10253-1-1999, EN10253-2-2007, EN10253-3-2008, EN10253-4-2008 |

| DIN2605-1-1992, DIN2605-2-1995 |

| JIS B2311-2009, JIS B2312-2009, JIS B2313-2009 |

| GB/T12459-2005, GB/T13401-2005, GB/T10752-2005 |

| SH/T3408-1996, SH/T3409-1996 |

| SY/T0609-2006, SY/T0518-2002, SY/T0510-1998 |

| DL/T695-1999, GD2000, GD87-1101 |

| HG/T21635-1987, HG/T21631-1990 |

Dimension

| Type | External Diameter | Wall Thickness |

| Seamless Type | 0.5-24 inches(DN15-DN600) | 4-150mm (sch10, sch20, sch30, std, sch40, sch60, xs, sch80, sch100, sch120, sch140, sch160, xxs, sch5s, sch20s, sch40s, sch80s) |

| Welded Type | 4-78 inches(DN150-DN1900) |

Material

| Carbon Steel | ASTM/ASME A234 WPB, WPC |

| Alloy Steel | ASTM/ASME A234 WP 1, WP 12, WP 11, WP 22, WP 5, WP 91, WP 911 |

| Stainless Steel | ASTM/ASME A403 WP 304, 304L, 304H, 304LN, 304N |

| ASTM/ASME A403 WP 316, 316L, 316H, 316LN, 316N, 316Ti | |

| ASTM/ASME A403 WP 321, 321H | |

| ASTM/ASME A403 WP 347, 347H | |

| Low Temperature Steel | ASTM/ASME A402 WPL 3, WPL 6 |

| High Performance Steel | ASTM/ASME A860 WPHY 42, 46, 52, 60, 65, 70 |

Production Process

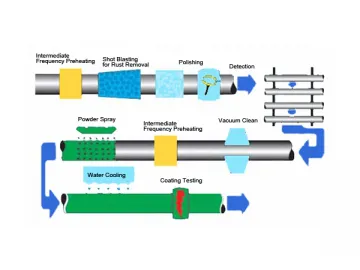

The pipe reducer is manufactured through the cold or hot processing methods embracing bending, extruding, pushing, mold pressing and machining.

Applicable Industry

The pipe reducer can be applied in a variety of fields, such as petroleum, natural gas, electric power, petrochemical engineering, ship, metallurgy, papermaking, heat supply, etc.

Scan QR to Read

Links:https://globefindpro.com/products/84902.html

Links:https://globefindpro.com/products/84902.html

Recommended Products

-

API Steel Oilfield Pipe

API Steel Oilfield Pipe

-

Cement Mortar Lined Steel Pipe

Cement Mortar Lined Steel Pipe

-

17.5 Inch Steel Wheel

17.5 Inch Steel Wheel

-

API 5L Steel Pipe

API 5L Steel Pipe

-

Prefabricated Insulated Pipe for Underground Installation

Prefabricated Insulated Pipe for Underground Installation

-

3 Layer PE Coated Steel Pipe

3 Layer PE Coated Steel Pipe

-

Pipe Gasket

Pipe Gasket

-

Steel Jacketed Insulated Pipe

Steel Jacketed Insulated Pipe

-

Seamless Stainless Steel Pipe

Seamless Stainless Steel Pipe

-

HS58 Radial Ply Tire

HS58 Radial Ply Tire

-

Single Layer Epoxy Coated Steel Pipe

Single Layer Epoxy Coated Steel Pipe

-

TCT Saw Blade

TCT Saw Blade