Reactor

Air-core Reactor

1. Product Overview

The CKGKL dry type air-core reactor is connected in series with the high voltage shunt capacitor bank to achieve the purposes of suppressing gird voltage waveform distortion, controlling the harmonic components flowing through the capacitor bank, and limiting the inrush current produced when the capacitor bank is switched on.

2. Features

a. Our dry type air core reactor adopts multilayer parallel windings;

b. Each winding is wound by insulated conductor with a small cross section;

c. The reactor is encapsulated by epoxy glass fiber and cured by high temperature, which has high strength and strong short-circuit shock resistance;

d. The wire terminals of each layer of winding are soldered to the upper and lower aluminum alloy star-shaped bracket;

e. Our product adopts natural air cooling. Its surface is coated with anti-aging, anti-UV weather-resistant paint;

f. The product has small loss, high strength, and low noise. It is easy to install and maintain. Its service life reaches 30 years.

| Model | Shunt capacitor bank capacity kvar | Rated voltage of capacitor kV | Rated current A | Rated reactance rate % | Rated reactance Ω | Short-time current KA | Single-phase capacity kvar | Single phase loss 75℃ w | Dimensions | Base pitch diameter DC mm | Weight kg | Recommended installation method | ||

| DS mm | H mm | h mm | ||||||||||||

| CKGKL-15/6-4.5 | 1000 | 6.6/√3 | 87.7 | 4.5 | 1.95 | 1.949 | 15 | 940 | 920 | 560 | 285 | 670 | 80 | Stacking |

| CKGKL-17/6-5 | 5 | 2.19 | 1.754 | 17 | 1000 | 920 | 585 | 285 | 670 | 87 | ||||

| CKGKL-20/6-6 | 6 | 2.62 | 1.462 | 20 | 1069 | 920 | 630 | 285 | 670 | 95 | ||||

| CKGKL-40/6-12 | 7.2/√3 | 80.1 | 12 | 6.23 | 0.667 | 40 | 1627 | 980 | 700 | 285 | 895 | 154 | ||

| CKGKL-43/6-13 | 13 | 6.74 | 0.616 | 43 | 1708 | 1005 | 700 | 285 | 925 | 162 | ||||

| CKGKL-18/6-4.5 | 1200 | 6.6/√3 | 105 | 4.5 | 1.633 | 2.33 | 18 | 1042 | 870 | 700 | 285 | 620 | 98 | Stacking |

| CKGKL-20/6-5 | 5 | 1.815 | 2.1 | 30 | 1101 | 870 | 600 | 285 | 620 | 106 | ||||

| CKGKL-24/6-6 | 6 | 2.718 | 1.75 | 24 | 1218 | 916 | 600 | 285 | 670 | 112 | ||||

| CKGKL-48/6-12 | 7.2/√3 | 96 | 12 | 5.184 | 0.8 | 48 | 1800 | 1000 | 670 | 285 | 920 | 176 | ||

| CKGKL-52/6-13 | 13 | 5.616 | 0.74 | 52 | 1927 | 1051 | 750 | 285 | 970 | 180 | ||||

| CKGKL-22.5/6-4.5 | 1500 | 6.6/√3 | 131 | 4.5 | 1.305 | 2.911 | 22.5 | 1200 | 915 | 740 | 285 | 670 | 108 | Stacking |

| CKGKL-25/6-5 | 5 | 1.452 | 2.62 | 25 | 1215 | 915 | 660 | 285 | 670 | 112 | ||||

| CKGKL-30/6-6 | 6 | 1.742 | 2.183 | 30 | 1400 | 960 | 680 | 285 | 720 | 130 | ||||

| CKGKL-60/6-12 | 7.2/√3 | 120 | 12 | 4.147 | 1.0 | 60 | 1980 | 1000 | 730 | 285 | 920 | 202 | ||

| CKGKL-65/6-13 | 13 | 4.493 | 0.923 | 65 | 2055 | 1060 | 750 | 285 | 978 | 210 | ||||

| CKGKL-24/6-4.5 | 1600 | 6.6/√3 | 140 | 4.5 | 1.22 | 3.11 | 24 | 1209 | 900 | 750 | 285 | 670 | 116 | Stacking |

| CKGKL-27/6-5 | 5 | 1.36 | 2.8 | 27 | 1340 | 900 | 700, | 285 | 670 | 118 | ||||

| CKGKL-32/6-6 | 6 | 1.64 | 2.33 | 32 | 1530 | 1000 | 700 | 285 | 770 | 124 | ||||

| CKGKL-64/6-12 | 7.2/√3 | 128 | 12 | 3.89 | 1.07 | 64 | 1878 | 1120 | 680 | 285 | 1040 | 226 | ||

| CKGKL-69/6-13 | 13 | 4.22 | 0.985 | 69 | 2040 | 1170 | 760 | 285 | 1068 | 230 | ||||

| CKGKL-27/6-4.5 | 1800 | 6.6/√3 | 157 | 4.5 | 1.089 | 3.489 | 27 | 1390 | 900 | 700 | 285 | 640 | 116 | Stacking |

| CKGKL-30/5-5 | 5 | 1.21 | 3.14 | 30 | 1482 | 935 | 700 | 285 | 690 | 120 | ||||

| CKGKL-36/6-6 | 6 | 1.452 | 2.617 | 36 | 1663 | 1010 | 710 | 285 | 770 | 132 | ||||

| CKGKL-72/6-12 | 7.2/√3 | 144 | 12 | 3.456 | 1.2 | 72 | 1980 | 1080 | 720 | 285 | 920 | 240 | ||

| CKGKL-78/6-13 | 13 | 3.744 | 1.108 | 78 | 2168 | 1104 | 740 | 285 | 920 | 252 | ||||

| CKGKL-36/6-4.5 | 2400 | 6.6/√3 | 210 | 4.5 | 0.81 | 4.667 | 36 | 1682 | 1115 | 720 | 285 | 870 | 141 | Stacking |

| CKGKL-40/6-5 | 5 | 0.907 | 4.2 | 40 | 1810 | 1215 | 720 | 285 | 970 | 151 | ||||

| CKGKL-48/6-6 | 6 | 1.089 | 3.5 | 48 | 1840 | 1100 | 650 | 285 | 1023 | 178 | ||||

| CKGKL-96/6-12 | 7.2/√3 | 192 | 12 | 2.592 | 1.6 | 96 | 2458 | 1260 | 700 | 285 | 1110 | 280 | ||

| CKGKL-104/6-13 | 13 | 2.808 | 1.477 | 104 | 2590 | 1310 | 700 | 285 | 1160 | 296 | ||||

4. Service and Installation Conditions

Elevation: 2000m

Wind speed: 35m/s

Ambient temperature: -40°C~ 45°C

Relative humidity: Monthly average 90%, daily average 95%

Installation site: Indoor or outdoor

The installation site should be kept from strenuous vibration or bump. The reactor could withstand seismic degree of 8 without damage. For indoor use, aeration and heat distribution should be paid enough attention to.

Related Names

Dry Type Reactor | Current Limit Reactor | Power System Protection Supplies

Links:https://globefindpro.com/products/85248.html

-

GGD AC Low Voltage Distribution Switchgear

GGD AC Low Voltage Distribution Switchgear

-

Fixed AC Metal-enclosed Switchgear

Fixed AC Metal-enclosed Switchgear

-

Seamless Reflective Vinyl Banner Material

Seamless Reflective Vinyl Banner Material

-

MNS-II Drawout Low Voltage Switchgear

MNS-II Drawout Low Voltage Switchgear

-

3H8000 Super Engineering Grade Prismatic Reflective Film

3H8000 Super Engineering Grade Prismatic Reflective Film

-

Reflective Plastic Sheet

Reflective Plastic Sheet

-

TKDM1L Residual Current Operated Circuit Breaker

TKDM1L Residual Current Operated Circuit Breaker

-

765kV Ultra High Voltage Transformer

765kV Ultra High Voltage Transformer

-

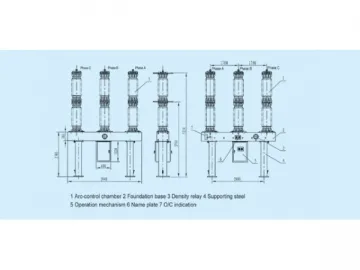

72.5~252kV SF6 Circuit Breaker

72.5~252kV SF6 Circuit Breaker

-

TKDM1 Molded Case Circuit Breaker

TKDM1 Molded Case Circuit Breaker

-

10~220kV Rectifier Transformer

10~220kV Rectifier Transformer

-

GW5 High Voltage Disconnector

GW5 High Voltage Disconnector