QT6-20B1 Concrete Block Making Machine

The QT6-20B1 concrete block making machine requires less labor intensity because of its full automatic operating system. It realizes the automation of plate feeding, plate discharging, and aggregate vibration. The concrete products that can be made by this machine include color floor tile, hollow blocks, etc.

Product Instruction

1. Our QT6-20B1 concrete block making machine adopts the crank-type aggregate drawer which is electrically controlled and comes with a braking system. Press the cylinder, then the secondary material scraping is carried out.

2. As a four-pillar jolt-squeeze molding brick making machine, it makes several blocks per time. The concrete blocks made by this machine each time, can be transported and stacked together.

3. This QT6-20B1 concrete block making machine is multifunctional. Its mold can be freely changed with ease.

4. It needs only 10 pallets. The concrete wall panel or floor tile made by our machine can be stacked directly. No drying is required.

5. The machine uses the special chasises, all of which are easily installed and debugged. Those chasises lower the failure rate.

6. The air-bag type mold clamping method is used for the die installation. Meanwhile, the mold clamping cylinder applies the hoisting assembly method.

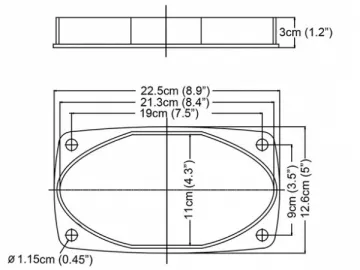

| Supporting Plate Size | 920*750*25mm |

| Forming Cycle | 20~25 seconds per time (Different product has different forming time)(Surface materials is excluded) |

| Product Height | 50~200mm |

| Forming Area | 875*700mm |

| Operating System | Full automatic |

| Total Installed Capacity | 33.75Kw |

| Overall Dimensions | 6, 420*2, 300*2, 850mm |

| Weight | 6, 900kg |

| Maxi. Pressure | 10t |

| Workers | 4 people (Full automatic, equipped with stacker and forklift) |

| Forming Method | Vibration and pressure |

| Output | 100m3 (mini. output per 8 hours ) 390*190*190mm |

| Executive Standard | JC/920-2011 Architecture material industry block machine |

Standard Configuration

Primary machine unit, pump station, surface material conveyor, ash bucket with silo, pallets feeder, bricks conveyor, conveyor, tool box, accessories, 20 pieces of 920*750*25bamboo plywood, operation instruction, warranty card, product delivery form, 4 trolleys, one set of 100*200 floor tile mold.

Remark

Raw Materials: Construction waste, coal ash, river sand, cement, stones, slag

Standard Blocks Output per Shift: 60,000 pieces per 8 to 10 hours

Floor Tile Daily Output: 30,000pieces

Finished Product

Related Names

Concrete Equipment | Cinder Block Machine | Paver Making Machine

Links:https://globefindpro.com/products/85558.html

-

QT9-20 Concrete Block Making Machine

QT9-20 Concrete Block Making Machine

-

QT4-20B2 Concrete Block Making Machine

QT4-20B2 Concrete Block Making Machine

-

QT10-15 Concrete Block Making Machine

QT10-15 Concrete Block Making Machine

-

QT5-35Z Concrete Block Making Machine

QT5-35Z Concrete Block Making Machine

-

BTS Mini Series

BTS Mini Series

-

QM5-18 Concrete Block Making Machine

QM5-18 Concrete Block Making Machine

-

QWT21 I Type Concrete Block Production Line

QWT21 I Type Concrete Block Production Line

-

ATS Series

ATS Series

-

Diaphragm Suction Pool Cleaner

Diaphragm Suction Pool Cleaner

-

Aluminum Outdoor Solar Shower

Aluminum Outdoor Solar Shower

-

Mould of Concrete Block Molding Machine

Mould of Concrete Block Molding Machine

-

European Style Series

European Style Series